Light-emitting element, illumination device, and liquid crystal display device

A technology for light-emitting elements and lighting devices, which is applied to lighting devices, optical elements, lighting and heating equipment, etc., can solve the problems of inability to obtain the uniformity of brightness of lighting devices, high cost, and obstacles to thinning of displays.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

[0110] [Embodiment 1: When the holding part is provided on the light emitting surface of the light guide]

[0111]

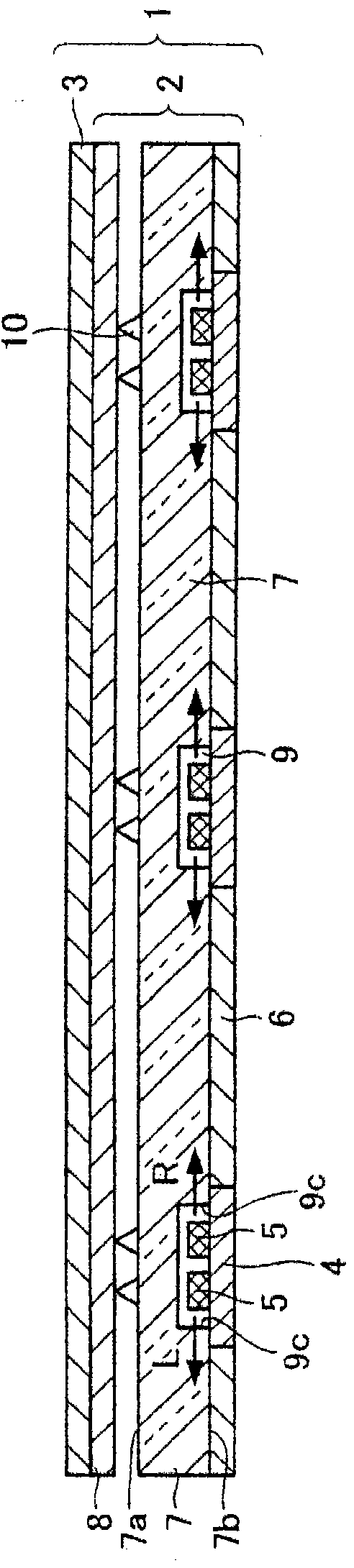

[0112] figure 2 It is a cross-sectional view showing a schematic configuration of a liquid crystal display device 1 according to an embodiment of the present invention. The liquid crystal display device 1 includes a backlight 2 (illumination device), and a liquid crystal display panel 3 arranged to face the backlight 2 .

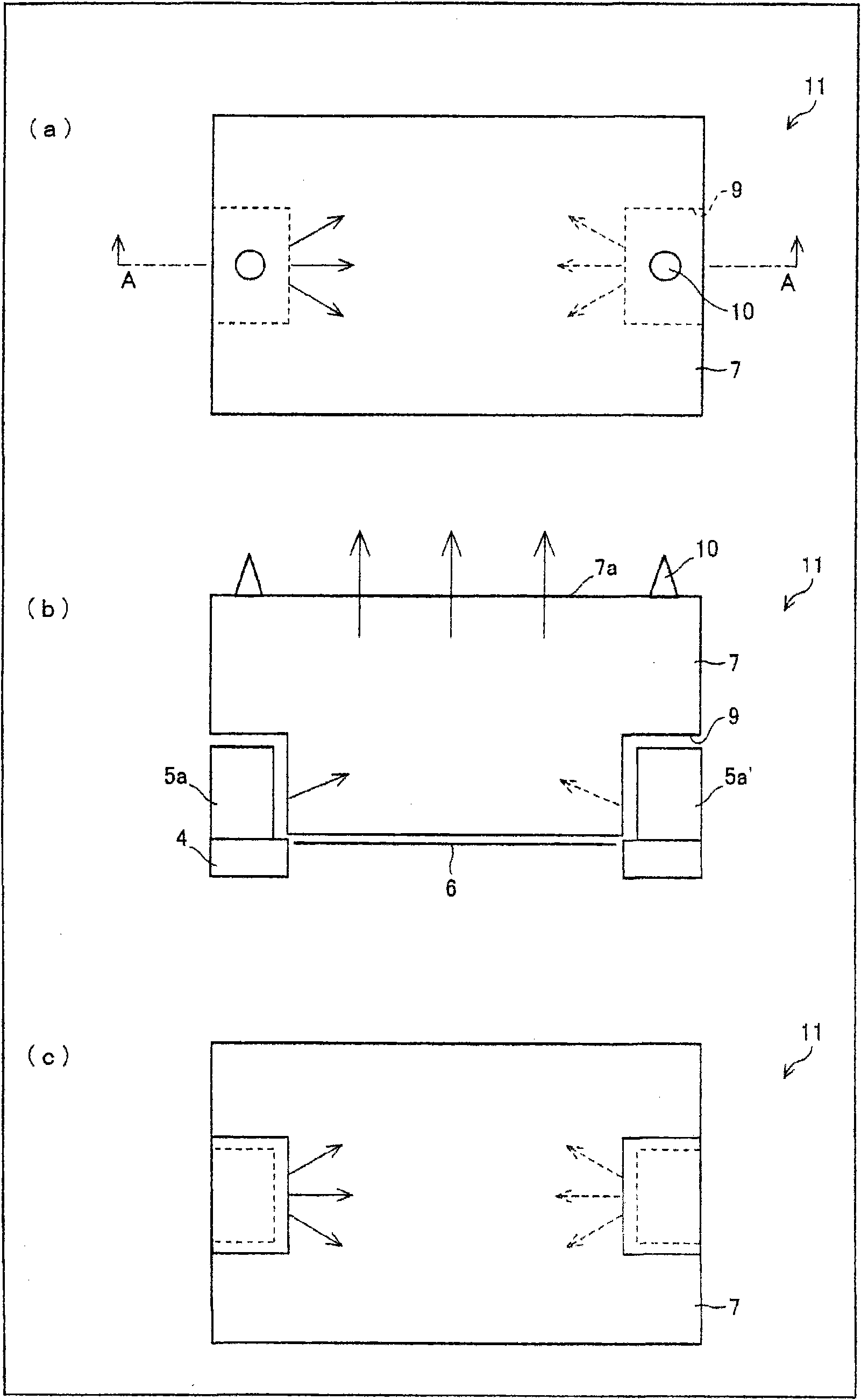

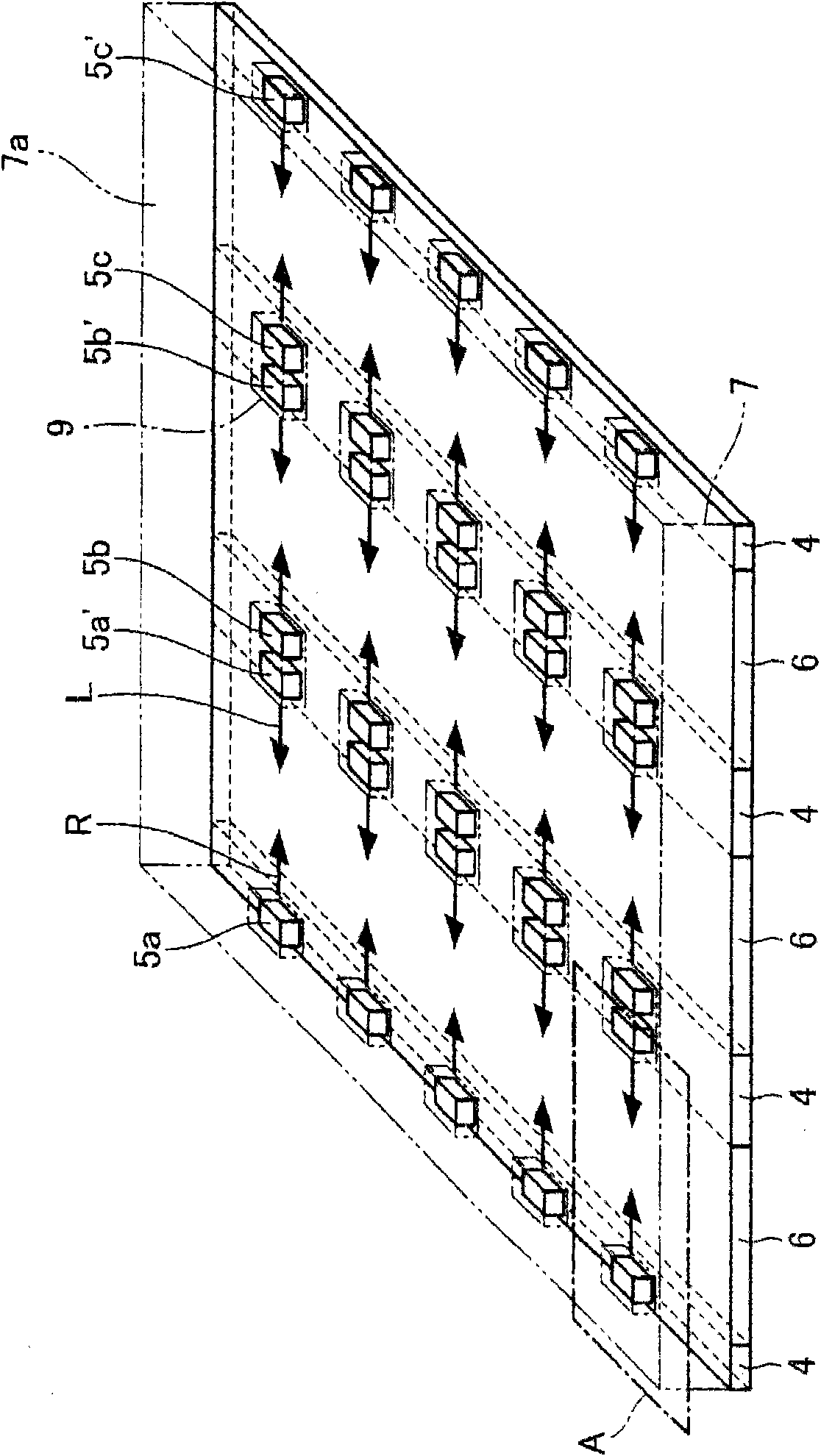

[0113] The backlight 2 is disposed behind the liquid crystal display panel 3 (on the side opposite to the display surface). Such as figure 2 As shown, the backlight 2 includes a substrate 4, a light source 5, a reflective sheet 6, a light guide 7, an optical sheet 8, and a holding portion 10 (first protrusion or second protrusion).

[0114] The liquid crystal display panel 3 is the same as a general liquid crystal display panel used in a conventional liquid crystal display device, and although not shown, includes, for example, an active...

Embodiment approach 2

[0200] based on the following Figure 18-20 Other embodiments of the present invention will be described. In addition, for convenience of explanation, components having the same structure and function as those shown in the drawings of Embodiment 1 above are denoted by the same reference numerals, and description thereof will be omitted.

[0201] Such as Figure 18 As shown, the liquid crystal display device 1 of the present embodiment differs from the first embodiment described above in terms of the arrangement of the holding portion 10 . In this embodiment, the holding part 10 is not provided on the light emitting surface 7a of the light guide 7 (refer to figure 2 ), but on the side of the optical sheet 8. Such as Figure 18 As shown, as an example of the form of providing the holding portion 10 on the optical sheet 8 side, the holding portion 10 may be formed integrally with the transparent plate 13 or integrally formed with the diffuser plate constituting the optical s...

Embodiment approach 3

[0210] based on the following Figure 21-22 Another embodiment of the present invention will be described. In addition, for convenience of explanation, components having the same structure and function as those shown in the drawings of Embodiment 1 above are denoted by the same reference numerals, and description thereof will be omitted.

[0211] Such as Figure 21 As shown, the liquid crystal display device 1 of this embodiment differs from the above-mentioned Embodiments 1 and 2 in the point of installation of the holding portion 10 . In this embodiment, the holding part 10 is not provided on the light emitting surface 7a of the light guide 7 (refer to figure 2 ), but integrally formed with the transparent plate 13, and the transparent plate 13 is fixed on the lower surface 8a of the optical sheet 8 opposite to the light-emitting surface 7a by an adhesive.

[0212] As a result, the holding portion 10 does not protrude upward from the light emitting surface 7 a toward the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com