Minimally invasive combined type absorbable interbody cage

An intervertebral fusion device and combined technology, applied in medical science, prostheses, spinal implants, etc., can solve the problems of non-adjustable fusion device height, delayed bone fusion, increased surgical volume, etc., and is beneficial to spinal fusion , promote bone graft fusion, and reduce the effect of surgical trauma

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

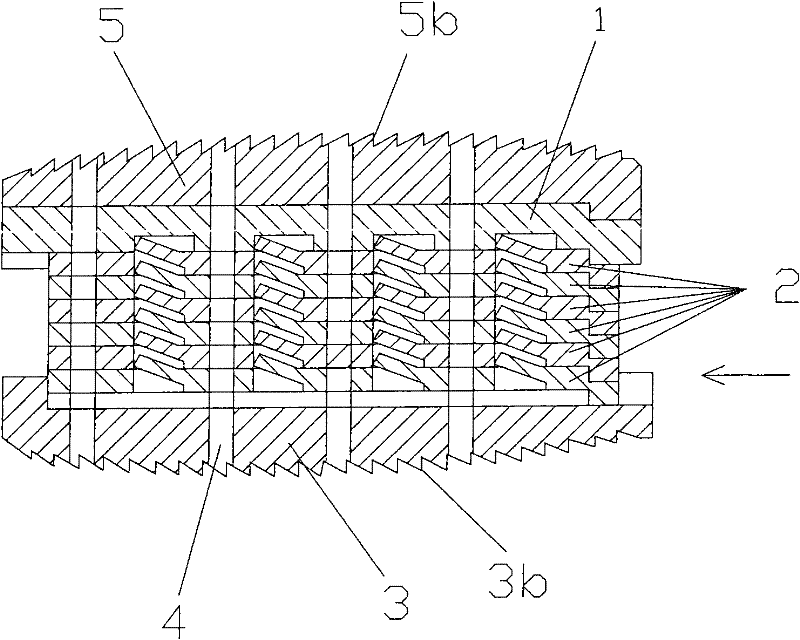

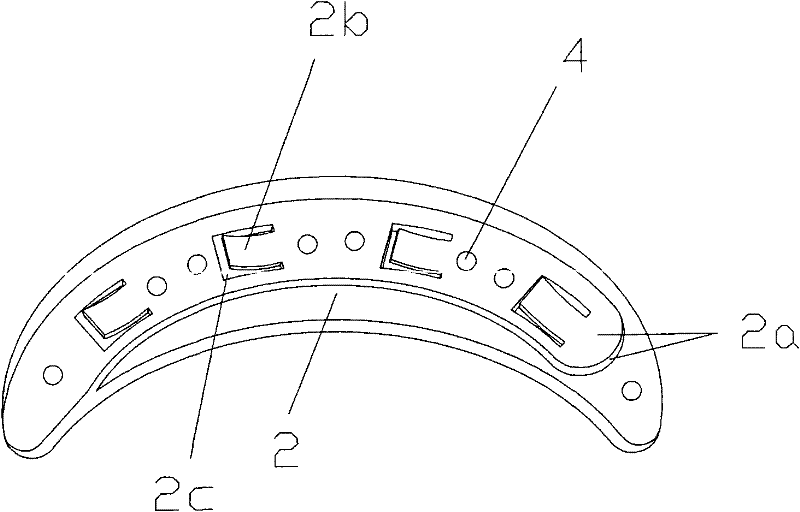

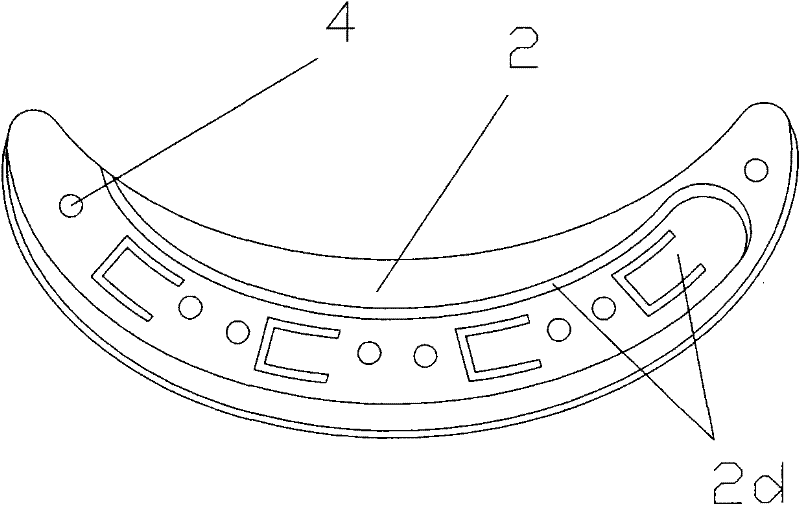

[0028] figure 1 A cross-sectional view of the overall structure of the minimally invasive combined absorbable intervertebral fusion device; figure 2 It is a schematic diagram of the three-dimensional structure of the arc-shaped convex table surface of the middle sheet; image 3 It is a schematic diagram of the three-dimensional structure of the arc-shaped groove surface of the intermediate sheet; Figure 4 It is a schematic diagram of the three-dimensional structure of the arc-shaped groove surface of the top sheet; Figure 5 It is a schematic diagram of the three-dimensional structure of the arc-shaped convex table surface of the top sheet; Figure 6 It is a schematic diagram of the three-dimensional structure of the arc-shaped groove surface of the top cover; Figure 7 It is a schematic diagram of the three-dimensional structure of the curved groove surface of the film.

[0029] As shown in the figure: this minimally invasive combined absorbable intervertebral fusion de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com