Numerical control upsetting tester

An experimental machine and experimental technology, applied in the field of experimental machines, can solve the problems of high cost and difficult to meet the needs of upsetting process research, and achieve the effect of low cost and rationality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] Below in conjunction with specific embodiment, and with reference to accompanying drawing, the present invention will be further described:

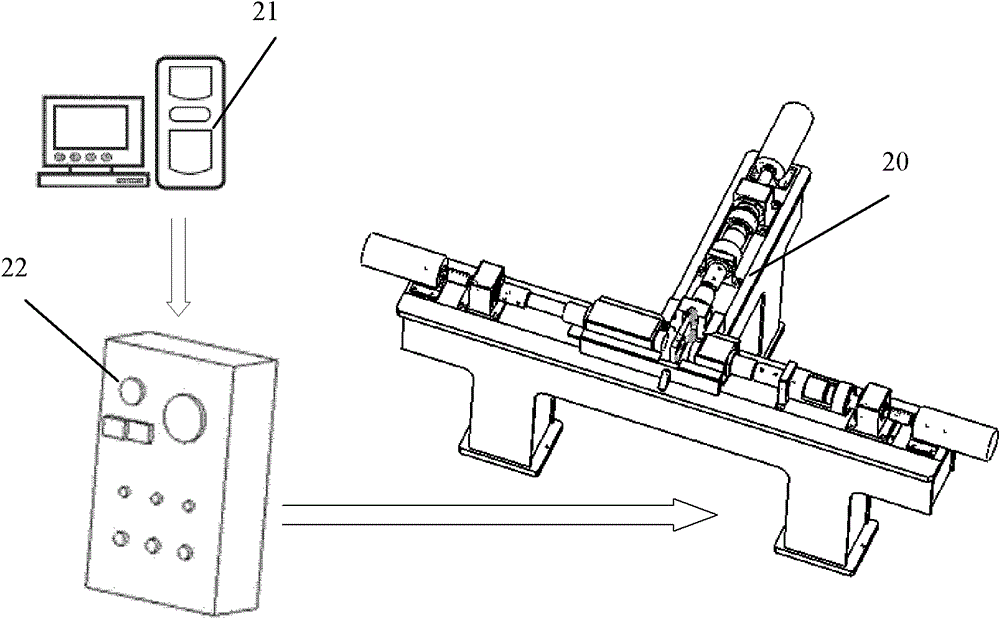

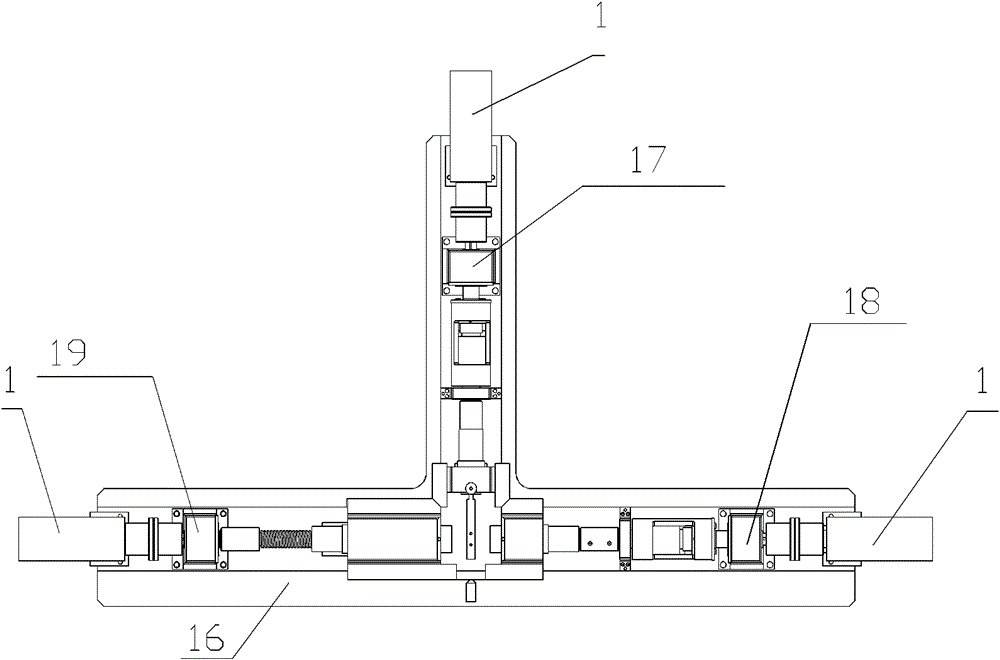

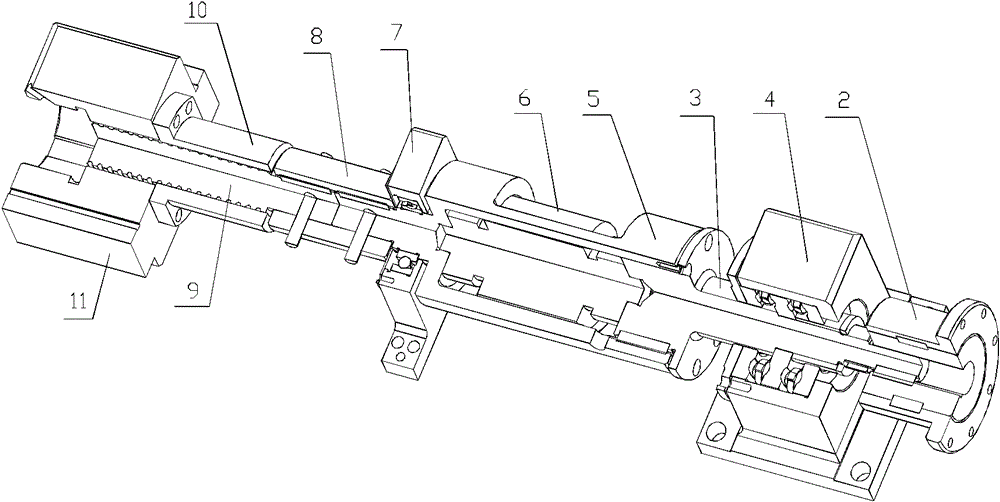

[0013] As shown in the accompanying drawing, the numerically controlled upsetting test machine includes an industrial computer 21 and a main machine 20 of the test machine. The main machine of the experimental machine includes the bed 16 and the left, right, and vertical three-axis linkage CNC transmission devices 17, 18, 19 installed on the bed 16 and arranged in a ⊥ shape with each other. The axes of the devices 19 and 18 are located on the same straight line, so the forces received during processing are the same in size and opposite in direction, so only the right transmission device is selected to measure the load. Described right transmission device is identical in structure with longitudinal transmission device. Both the right transmission device and the longitudinal transmission device include a stepping motor 1, and the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com