Processing method for crushing slag

A processing method and technology for steel slag, applied in the fields of crushing, processing, sorting and preparing steel slag powder, can solve the problems of difficult processing of steel slag, and achieve the effect of promoting the development of comprehensive utilization level

Inactive Publication Date: 2010-11-24

BEIJING KAITE CRUSHER

View PDF1 Cites 30 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The purpose of the present invention is to provide a crushing and processing method for steel slag, solve the problem that steel slag is difficult to process, and provide a reasonable preparation method for steel slag micropowder

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

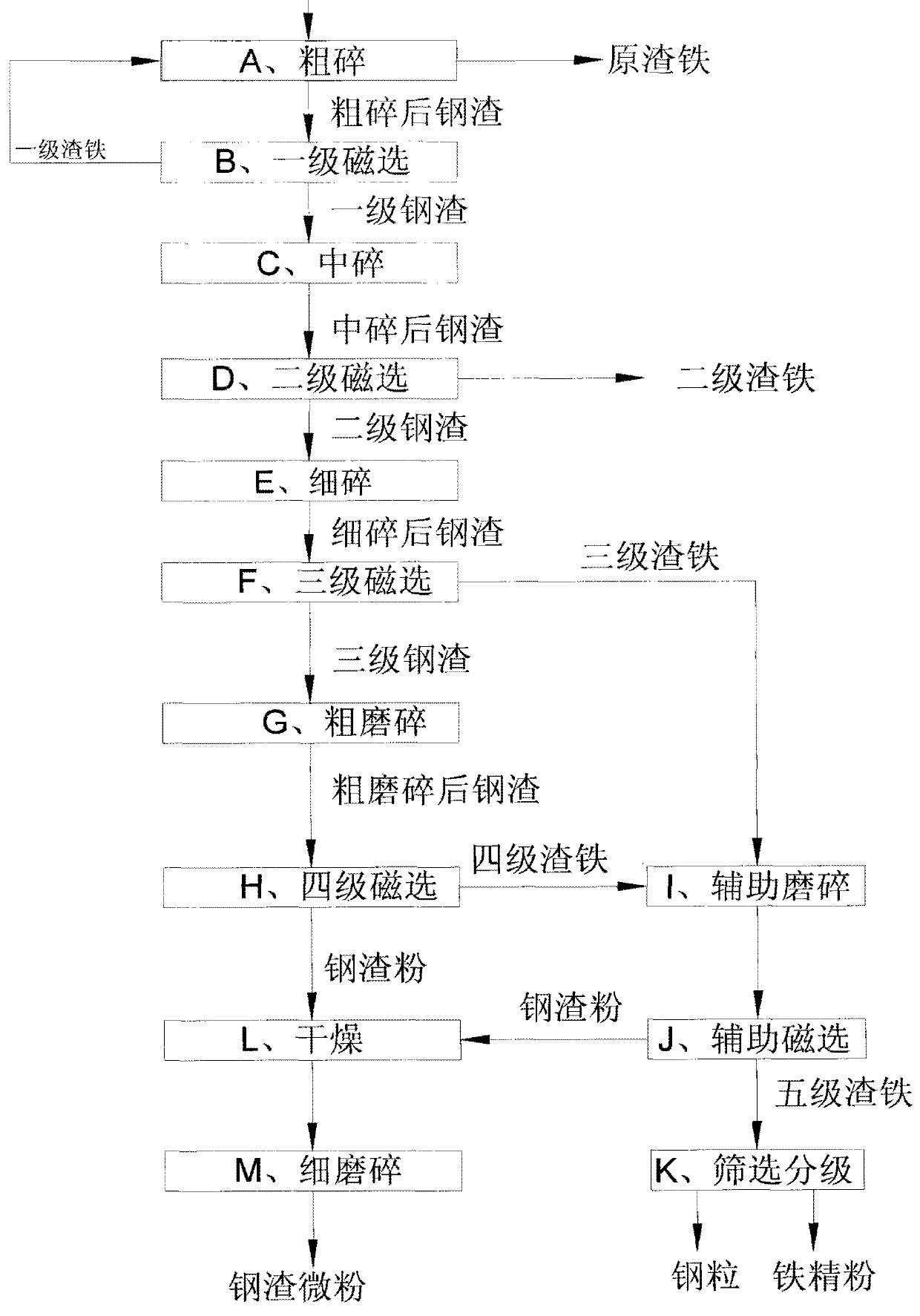

The invention discloses a processing method for crushing slag, comprising the following steps: conducting multi-level crushing, carrying out magnetic separation and grinding. The invention solves the problem that slag is hard to process and provides a reasonable preparation method for slag micro powder. In the method, after the slag is crushed for many times, separated magnetically and grinded, over 99.2% magnetic iron and residues contained in the slag are separated; the obtained products, such as slag steel, steel shots and iron ore concentrate, can be used in iron and steel smelting; and the obtained slag micro powder with the 0.075mm weight of screen residue less than 1% and the specific surface area more than 580m<2> / kg can be applied to cement production or replace part of cement to be used as an admixture of concrete, thereby realizing absolute and effective utilization of slag and accelerating comprehensive utilization level of the solid waste of the slag.

Description

A method for crushing and processing steel slag technical field The invention relates to the technical field of mechanical processing, in particular to a method for crushing and processing steel slag, which is used for sorting and preparing steel slag (fine) powder. Background technique Steel slag is a by-product of the steelmaking industry. With the development of the steelmaking industry, a lot of steel slag is produced every year. Its dumping not only takes up a lot of land, pollutes the surrounding environment, but also causes a waste of resources, which is very unfavorable to environmental protection and circular economy. . Steel slag has a special structure, which is a combination of slag and iron (steel). Some blocks are mainly slag, and some are mainly iron; some are slag-coated iron, and some are iron-coated slag. It is very difficult for existing jaw crushers to crush steel slag coarsely and mediumly, and for cone crushers to crush steel slag finely. The crushe...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): B22F9/04C21B3/06

CPCY02W30/50

Inventor 夏晓鸥陈帮罗秀建刘方明王旭

Owner BEIJING KAITE CRUSHER

Features

- Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com