Rigid out-covered clamping device of vertical fine boring machine

A fine boring machine and rigid technology, applied in the field of rigid outsourcing clamping devices, can solve the problems of frequent replacement and adjustment, low fixture accuracy, low qualification rate, etc., and achieve the effect of ensuring shape and position tolerance, improving quality and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

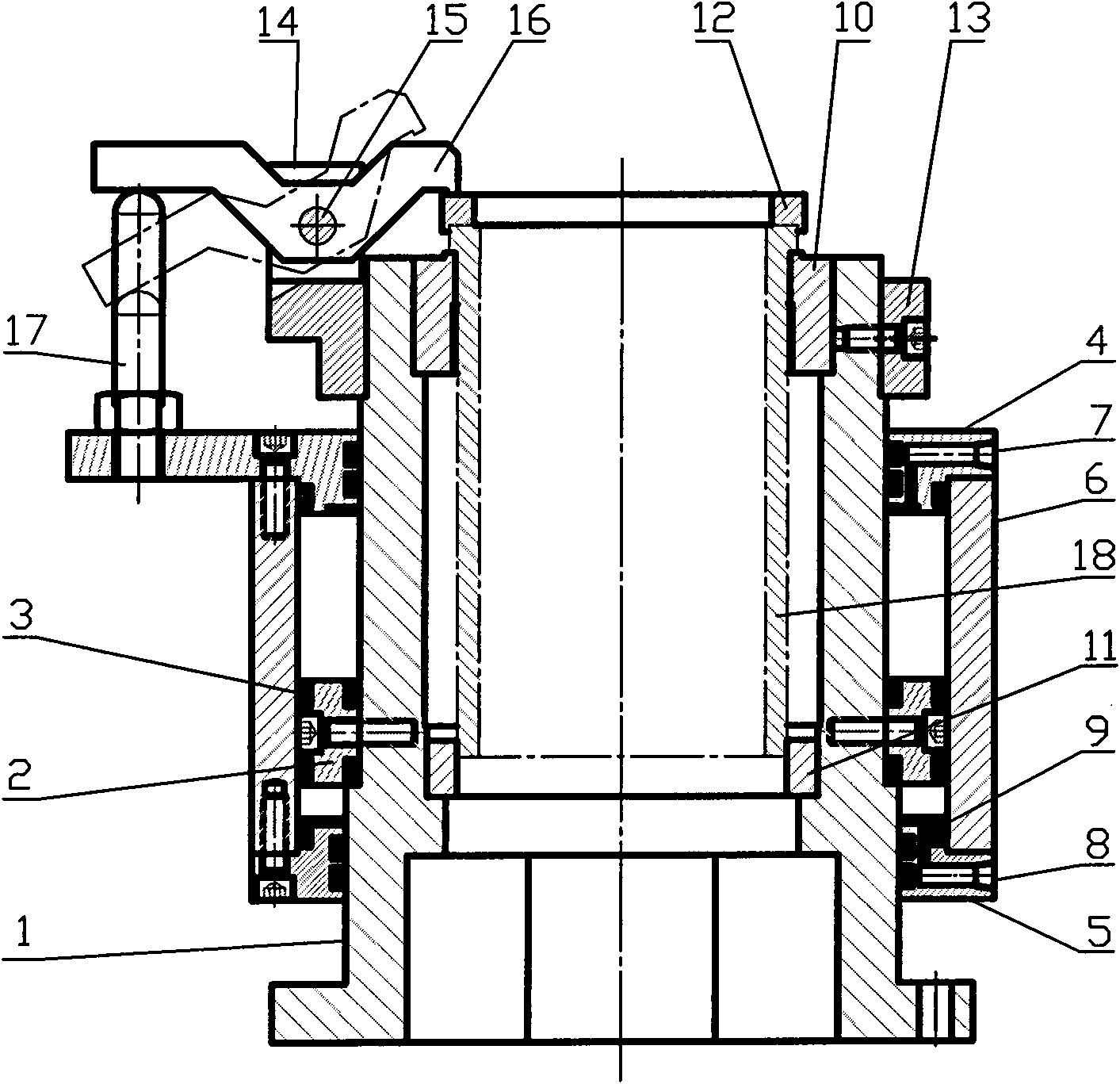

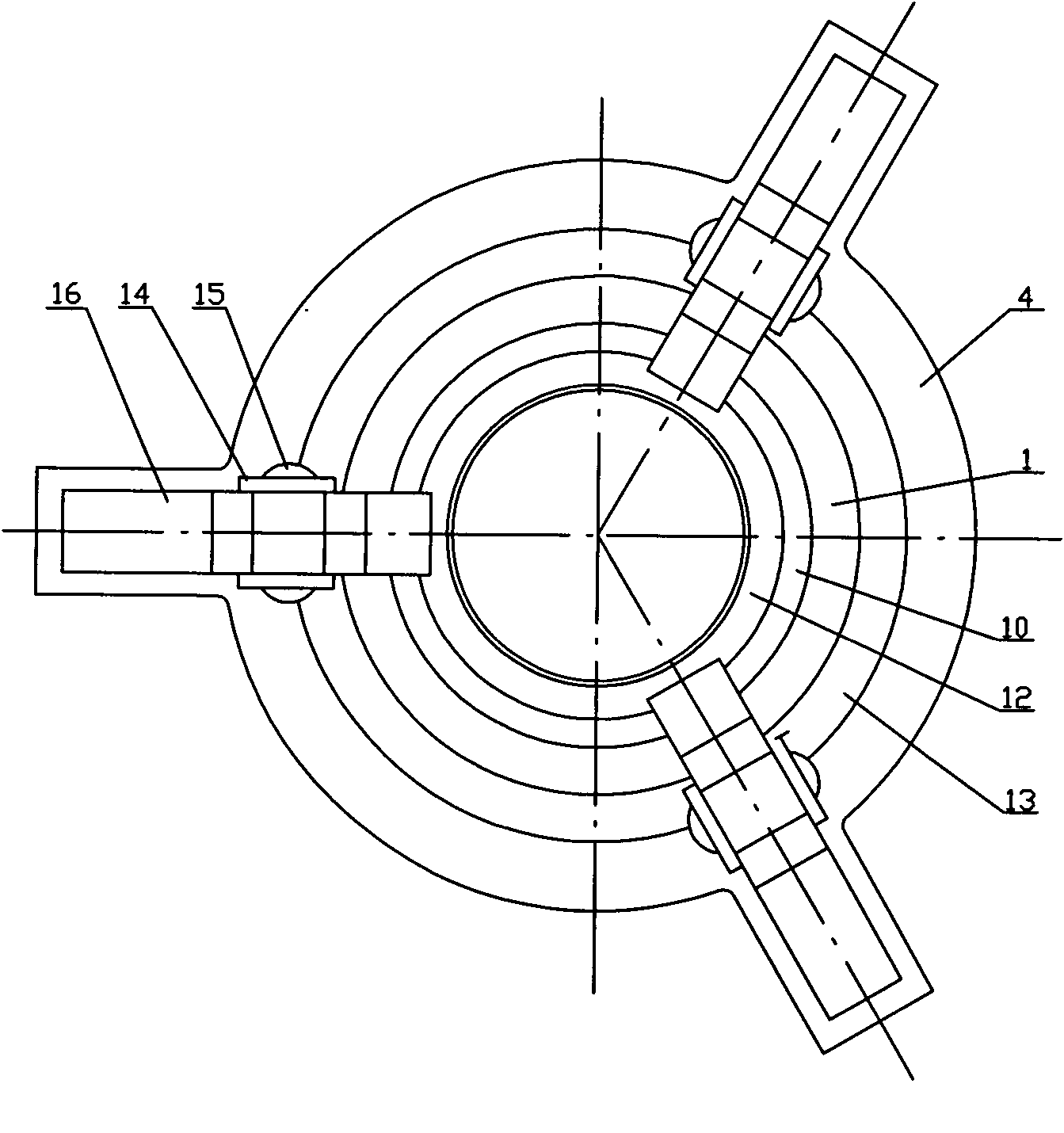

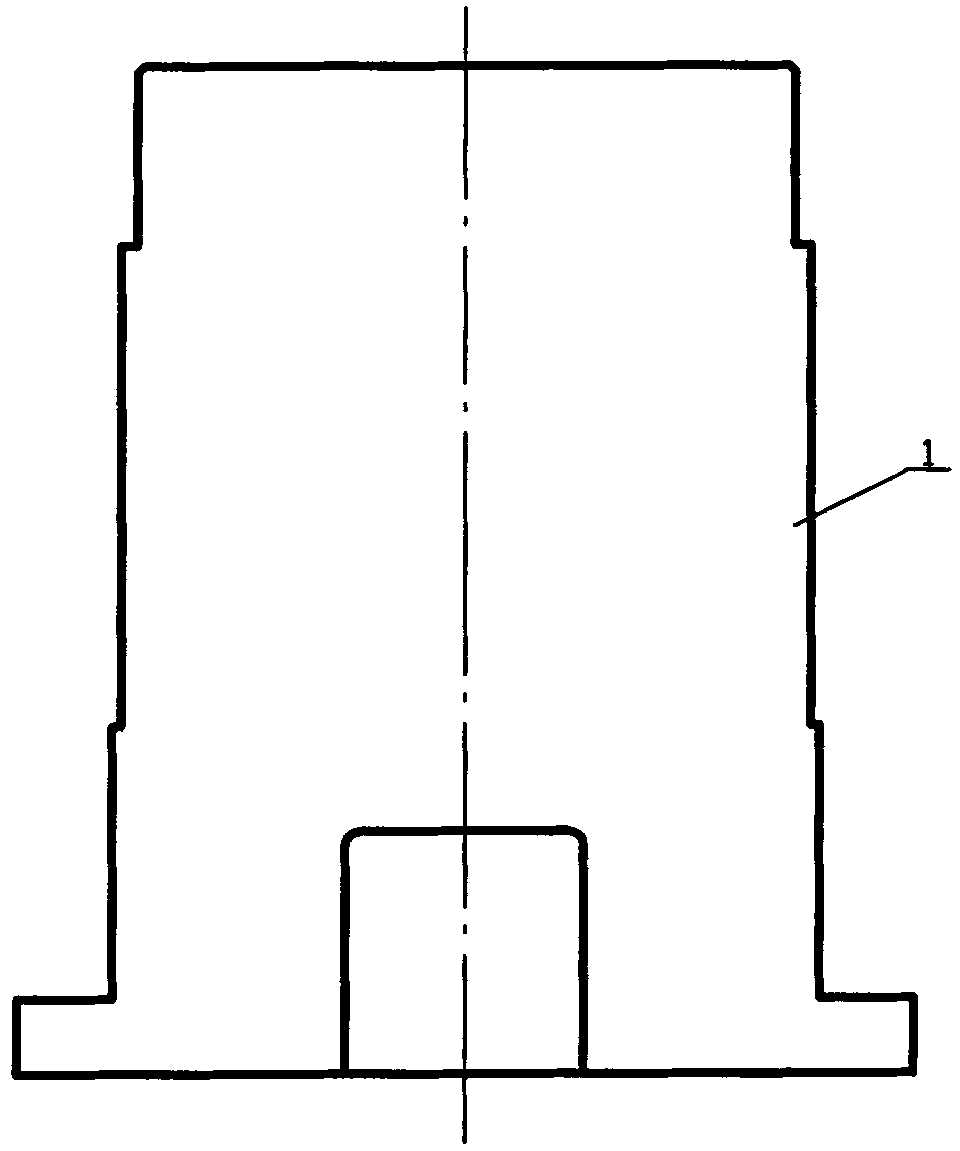

[0010] Depend on figure 1 , figure 2 and image 3 It can be seen that the rigid outsourcing clamping device of the vertical fine boring machine of the present invention includes a clamp tube 1, the connecting seat and the clamp tube 1 are an integral structure, and the connecting seat is provided with a connecting hole for connecting with the boring machine. The lower part of the outer wall of the fixture cylinder 1 is provided with a fixed ring 2, and the fixed ring 2 is matched with the inner wall of the sleeve 6 on which the upper flange 4 and the lower flange 5 are fixed through the O-shaped sealing ring 3. The length of the sleeve 6 is shorter than that of the clamp cylinder. 1, the sleeve 6 is provided with an upper vent hole 7 and a lower vent hole 8, and the inner end faces of the upper flange 7 and the lower flange 8 are matched with the outer wall of the fixture cylinder 1 through the O-ring 9, and the fixture The inner wall of the cylinder 1 is provided with an u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com