Guide sleeve for concrete nail

A technology of guide sleeves and cement nails, applied in nail dispensers, packaging, manufacturing tools, etc., can solve problems such as bending, nails can't go in, and cement nails have problems.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

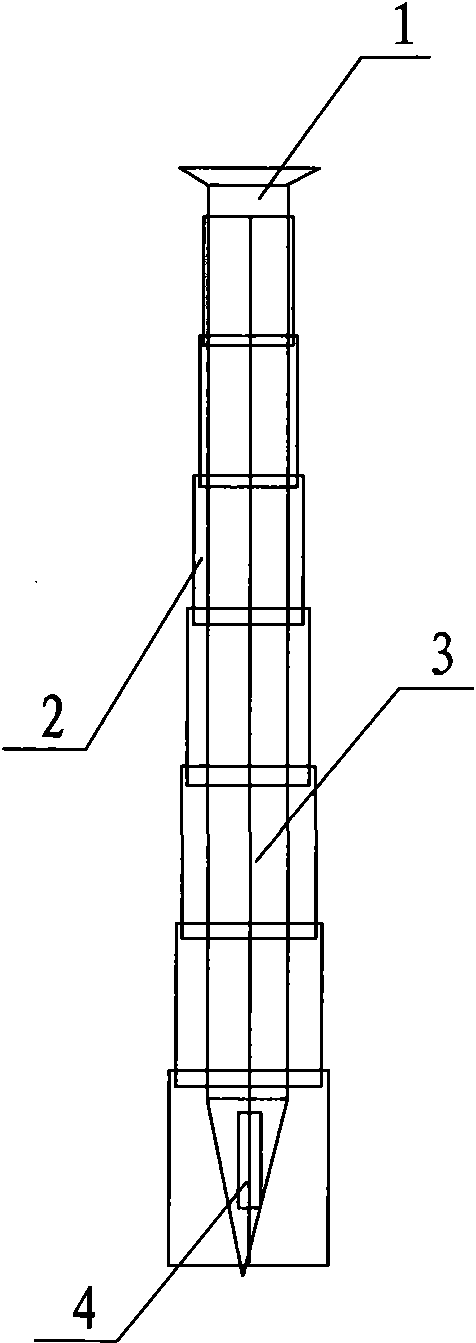

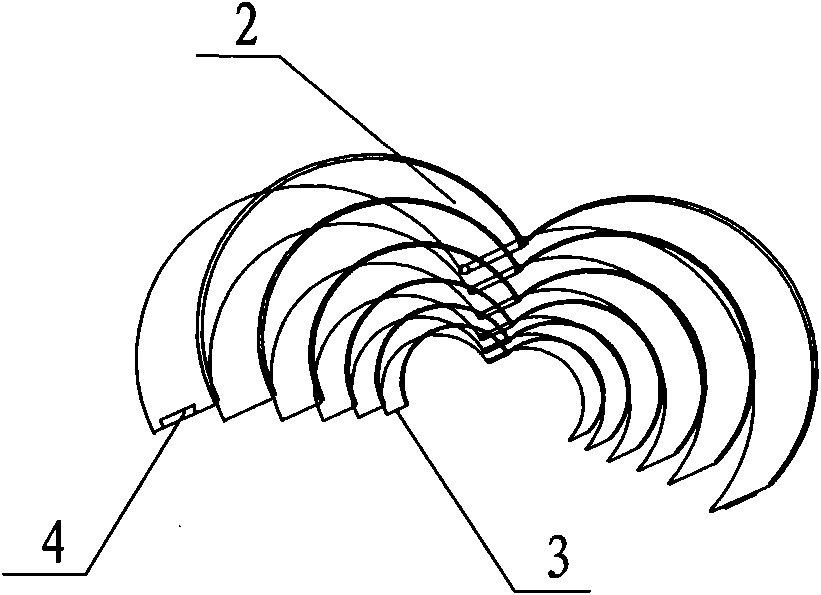

[0011] Such as figure 1 , figure 2 As shown, a guide sleeve for cement nails includes a fishing rod type multi-layer rigid ring body 2, and the inner wall of the innermost rigid ring body closely fits with the outer circumference of the cement nail 1. When nailing cement nails, on the one hand, because the inner wall of the innermost rigid ring fits closely with the outer circumference of the cement nails, the direction of the cement nails will not be deflected; The body is shortened accordingly, and the inner wall is always in close contact with the outer circumference of the cement nail, so that the possibility of the nail becoming bent is lower.

[0012] Each layer of rigid ring body 2 is composed of two semi-ring shaft connections, and a connecting clip 4 is provided on the connecting line 3 opposite to the shaft connection part of the outermost rigid ring body. Elastic clips are arranged on the connecting shafts of the two half-rings of each rigid ring body 2, and both...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com