Split rotating shaft joint

A rotating shaft, split-type technology, applied in the direction of load hanging components, earthmoving machines/shovels, construction, etc., can solve the problems of difficult to ensure coaxiality, difficult processing, difficult detection, etc., to achieve measurement and operation. Strong performance, simple processing technology, good dimensional accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

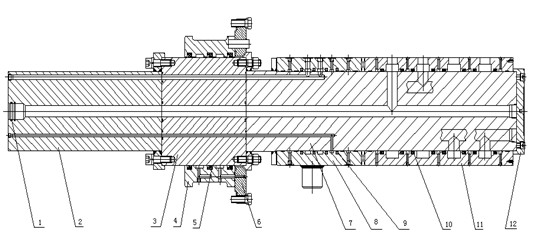

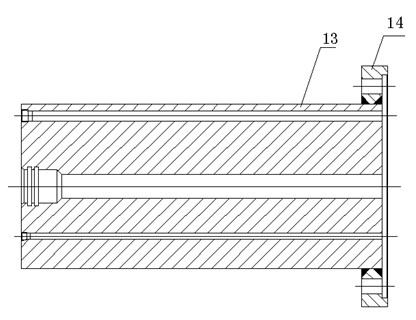

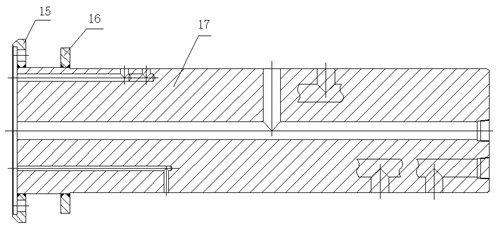

[0019] Such as figure 1 As shown, a split rotary shaft joint provided by the present invention includes split front shaft 2, central shaft 3, rear shaft 7, middle sleeve 4, oil distribution sleeve 8 and water distribution sleeve 11. After assembly, the central shaft 3 Located between the front axle 2 and the rear axle 7, a rear cover 12 is provided on the rear end of the rear axle 7, a middle sleeve 4 is placed on the center axle 3, and an oil distribution sleeve 8 and a water distribution sleeve 11 are placed on the rear axle 7 , guide rings are respectively embedded on the inner walls of the oil distribution sleeve 8 and the water distribution sleeve 11. There is a large flange 6 over the central shaft 3, and the large flange 6 is located at the side of the middle sleeve 4, and the seal between the large flange 6 and the middle sleeve 4 is sealed by an O-ring.

[0020] The middle shaft 3 and the middle sleeve 4 are sealed by soil and sand 5, the oil distribution sleeve 8 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com