Shield tunnel segment lining anti-seismic longitudinal joint

A technology of shield tunnel segment and longitudinal joint, which is applied in tunnel lining, tunnel, wellbore lining and other directions, can solve the problem that the seismic capacity needs to be improved, and achieve the effect of easy promotion and easy implementation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

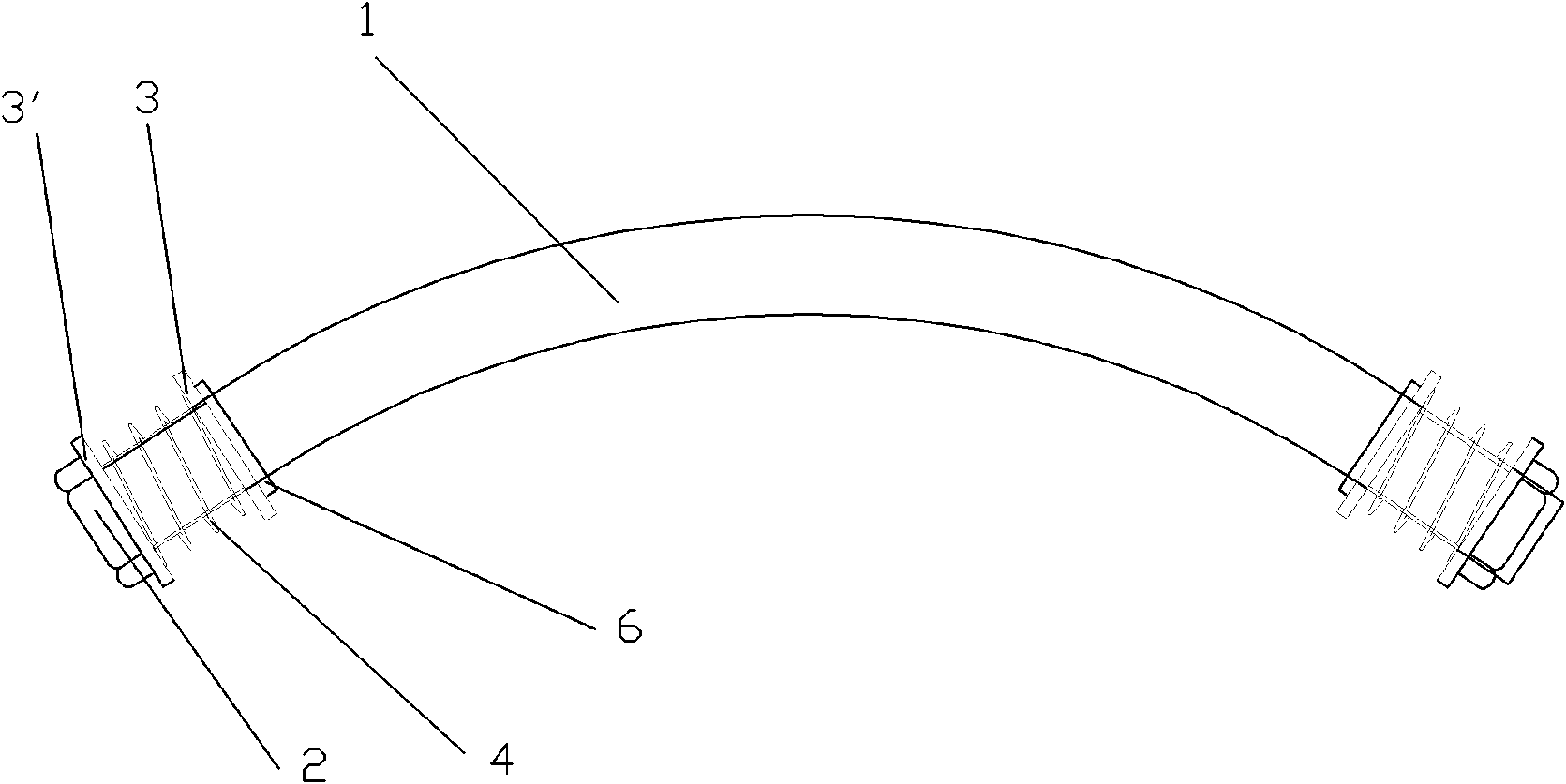

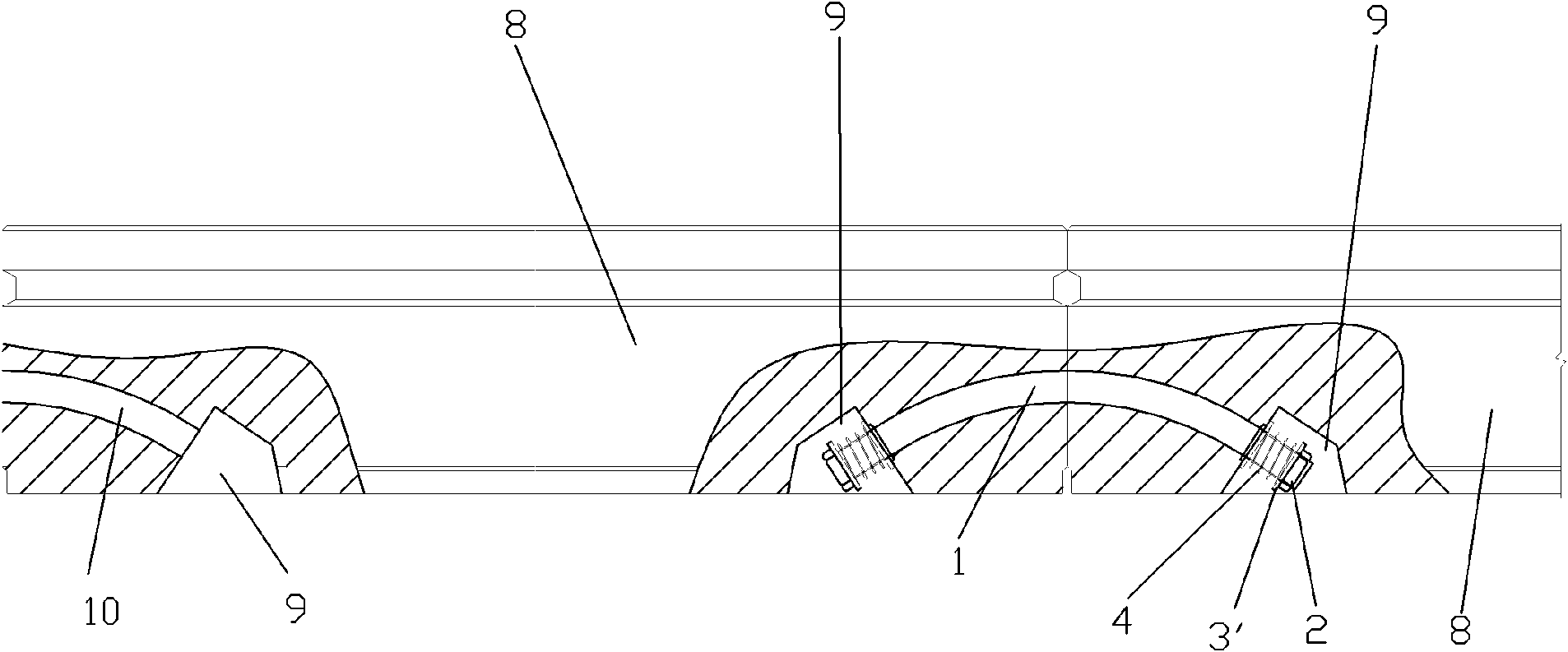

[0034] figure 1 , 2 As shown, a specific embodiment of the present invention is: a shield tunnel segment lining anti-seismic longitudinal joint, including a screw 1, a nut 2 at both ends of the screw 1, a washer 3 and a water-swellable rubber 6 on the inner side of the nut 2 in sequence . An elastic device 4 is fitted on the screw 1 between the washer 3 and the nut 2 . An outer gasket 3' is sleeved between the water-swellable rubber 6 and the elastic device 4. The elastic device 4 is a spring.

[0035] figure 2 It is shown that the screw rod 1 of this example is inserted into the longitudinal (axial) perforation 10 between the hand holes 9 of two adjacent segment rings 8, the ends of the screw rod 1 at the hand holes 9 of the two segment rings 8 The water-swellable rubber 6, the washer 3, the elastic device 4 and the outer washer 3' are sequentially inserted from the inside to the outside, and then the nut 2 is tightened to realize the splicing of the segment rings 8.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com