Solenoid valve for active closing of solenoid injectors

A fuel injector, electromagnetic technology, applied to fuel injection devices, valve details, valve devices, etc., can solve problems such as no overpressure limit

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

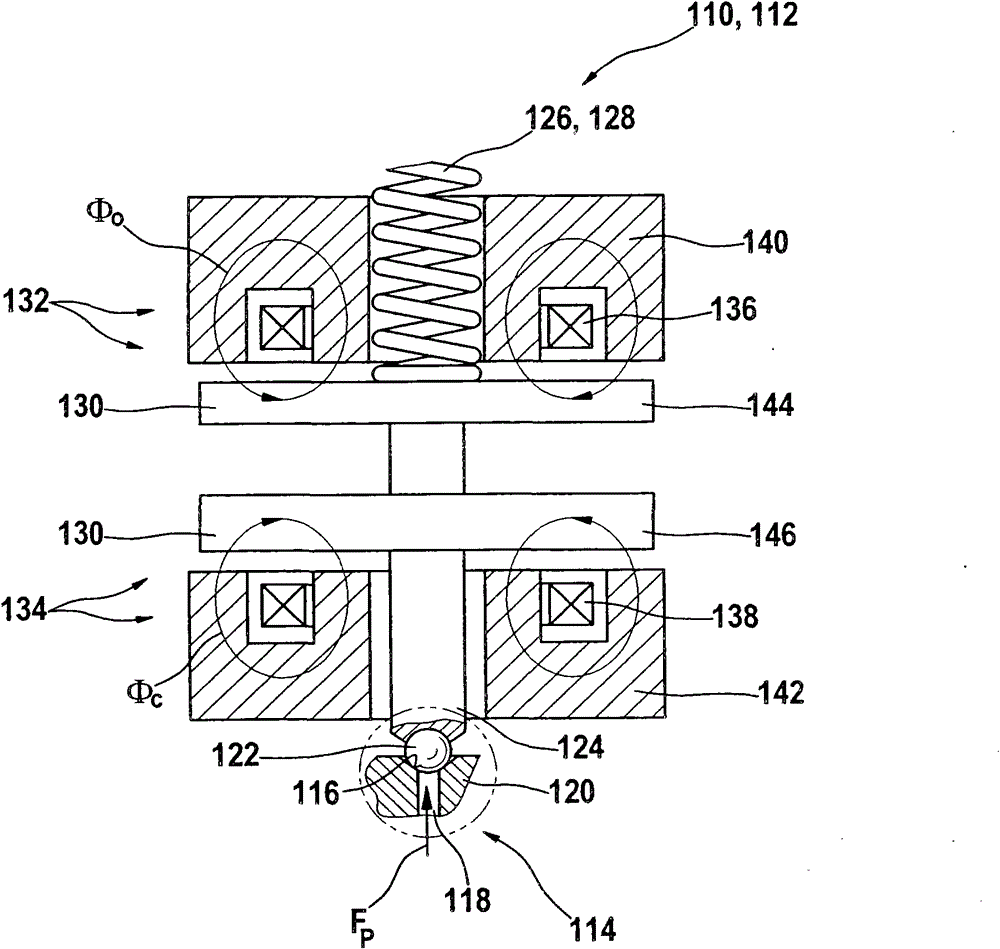

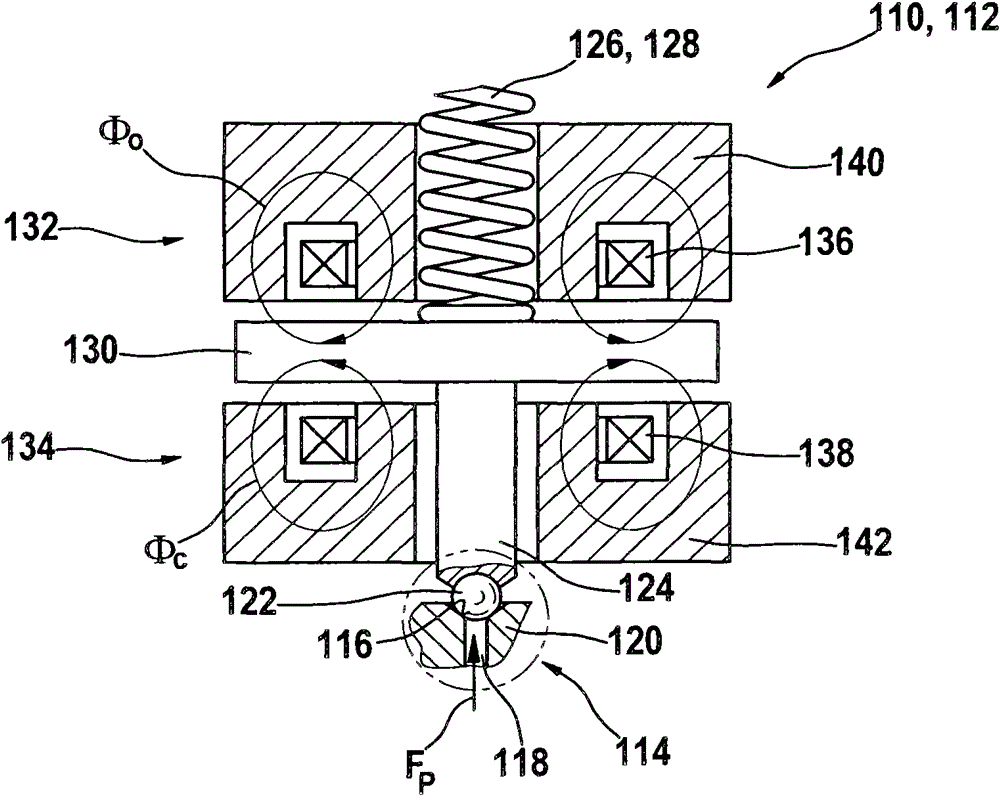

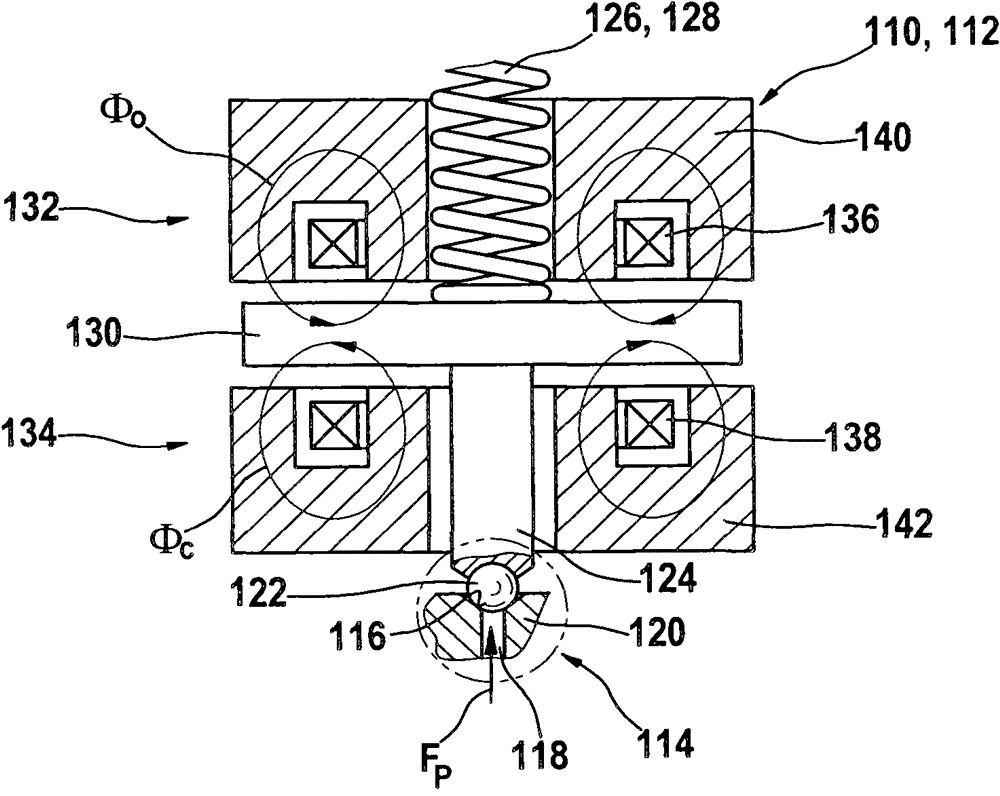

[0028] exist Figures 1 to 4B Various different embodiments of the hydraulic valve 110 that may be used in the fuel injector 112 are shown in . Other portions of fuel injector 112 are not shown in the drawings. Hydraulic valve 110 can be accommodated, for example, in an injector housing (not shown) of fuel injector 112 in which, for example, an injection valve element can also be supported. Each hydraulic valve 110 has a valve region 114 with a valve seat 116 and a valve bore 118 . The valve seat 116 and the valve opening 118 can be formed, for example, in an injector body 120 , which is only shown schematically. The valve opening 118 can, for example, open directly or indirectly into a control chamber of the fuel injector 112 , via which the stroke of the injection valve element can be controlled. Furthermore, the hydraulic valve 110 has a closing element 122 in the valve region 114 , which in the exemplary embodiment shown is embodied as a ball. In principle, however, ot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com