Brightness enhancement film and backlight module

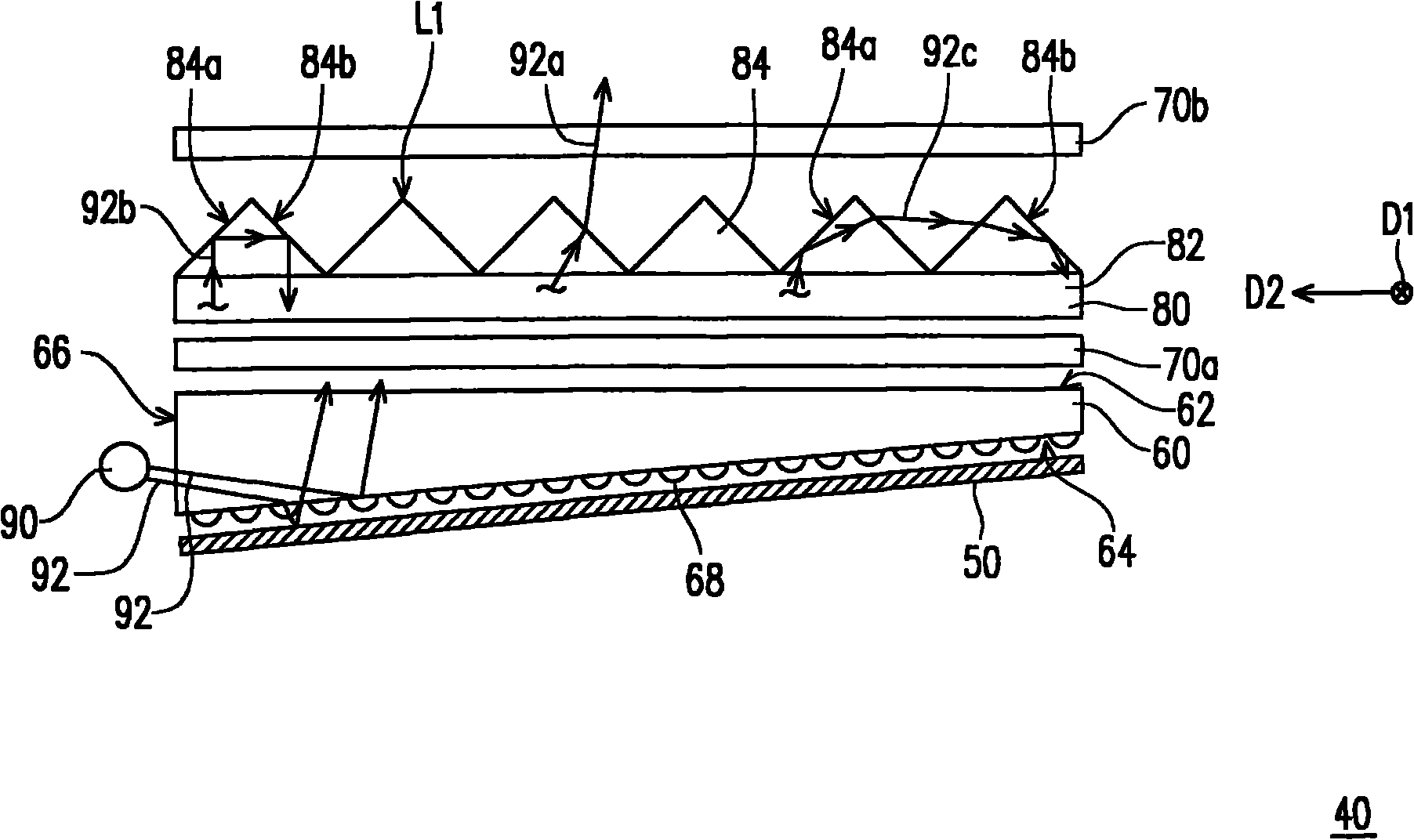

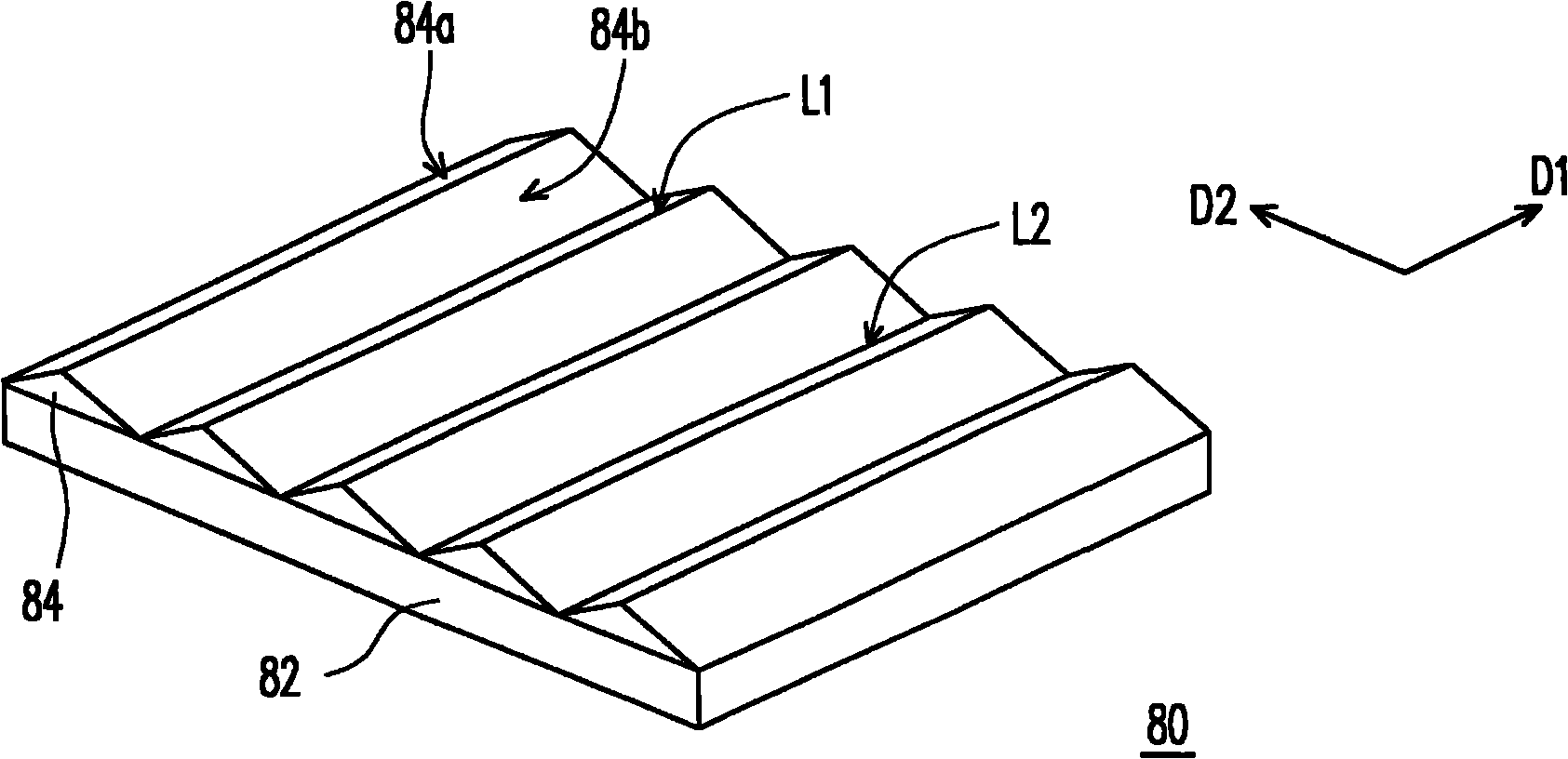

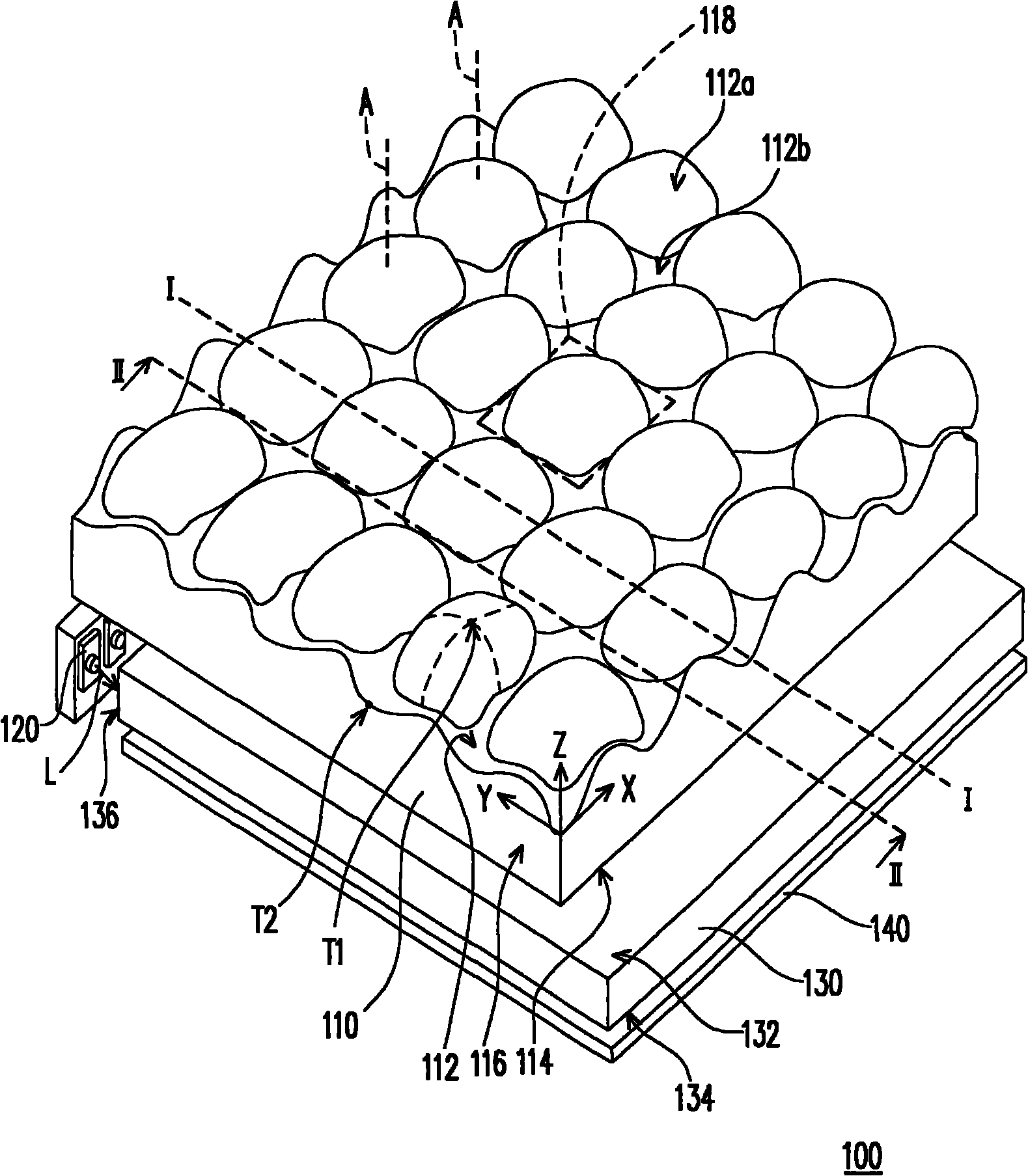

A light-enhancing sheet, axisymmetric technology, applied to lighting devices, components of lighting devices, refractors, etc., can solve the problems of reduced light efficiency, increased cost, increased thickness of backlight module 40, etc., to achieve uniform brightness and good shading characteristics, the effect of good light-gathering characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0071] The description of the following embodiments refers to the attached drawings to illustrate specific embodiments that the present invention can be implemented. The terms of the direction mentioned in the present invention, such as "up", "down", "front", "rear", "left", "right", etc., are only directions for referring to the attached drawings. Therefore, the directional terms used are used to illustrate rather than to limit the present invention.

[0072] In this specification, an object that is axisymmetric means that a symmetry axis can be found and after the object is rotated around the symmetry axis at any angle, the shape of the object can be substantially the same as the shape before the rotation. In addition, if an object is non-axisymmetric, it is defined as that no axis of symmetry can be found so that after the object is rotated at any angle around the axis of symmetry, the shape of the object can be substantially the same as the shape before the rotation.

[0073] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com