Biomass boiler capable of realizing combined combustion of synthesis gas and semicoke

A biomass boiler and synthesis gas technology, which is used in combustion equipment, the manufacture of combustible gas, the combustion of solid fuels, etc., can solve the problem of increased heat loss, low thermal efficiency of biomass boilers, and no consideration of the impact of semi-coke yield on combustion efficiency. and other problems to achieve the effect of solving low thermal efficiency and reducing ash corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

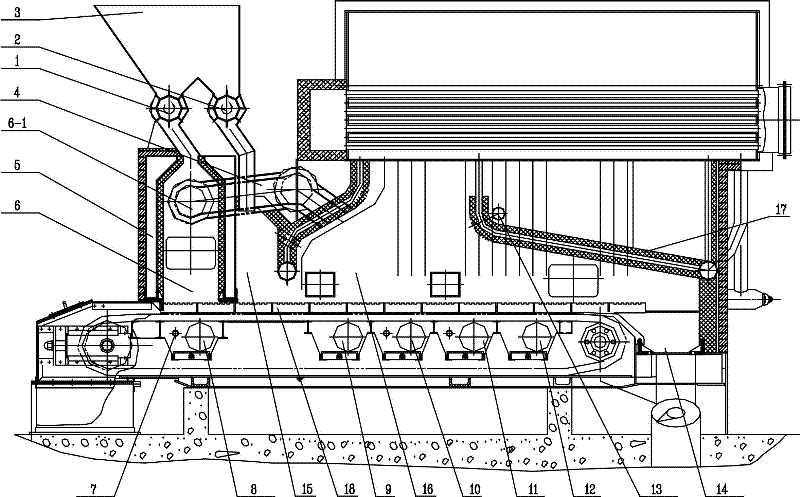

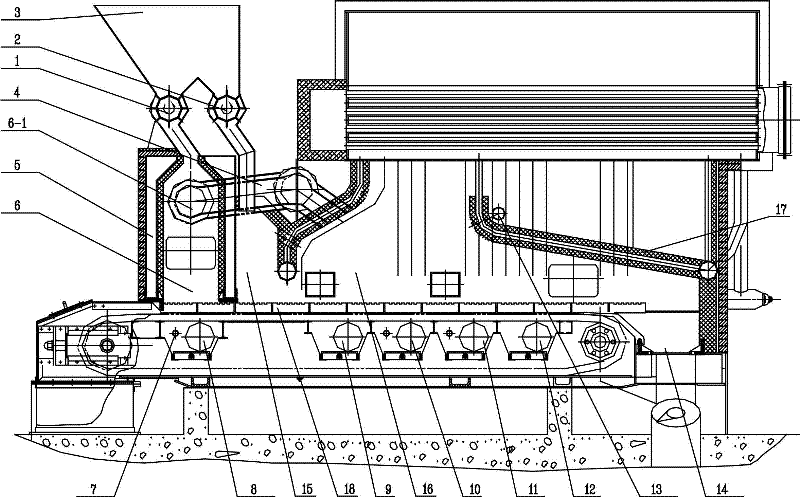

[0012] Specific implementation mode one: as figure 1As shown, a biomass boiler that can realize the combined combustion of syngas and semi-coke described in this embodiment includes a boiler body 17, a chain grate 18, a plurality of air chambers, a silo 3, a biomass gasification chamber 6, The gasification air chamber 8 and steam enter the pipe 7, and the inner cavity of the boiler body 17 is the furnace 16; the biomass boiler also includes a primary feeder 1, a secondary feeder 2, a semi-coke combustion chamber 15 and a syngas outlet Pipe 4; the biomass gasification chamber 6 is arranged at the inlet end of the boiler body 17, the semi-coke combustion chamber 15 is arranged between the biomass gasification chamber 6 and the boiler body 17, and the semi-coke combustion chamber 15 communicates with the furnace 16, and the chain The fire grate 18 is arranged under the biomass gasification chamber 6, the semi-coke combustion chamber 15 and the boiler main body 17, and the gasific...

specific Embodiment approach 2

[0013] Specific implementation mode two: as figure 1 As shown, the side wall of the biomass gasification chamber 6 in this embodiment is provided with a cavity 5 conforming to the side wall, and the cavity 5 is used to generate atomized steam. The cavity 5 is called an air interlayer, that is, the jacket of the biomass gasification chamber is composed of inner and outer furnace walls, with an air interlayer in the middle, and an atomizing nozzle connected to the water inlet pipe is arranged on the inner side of the outer furnace wall. The vaporized water vapor is sprayed into the air interlayer, and the heat generated by the partial combustion of the fuel in the gasification combustion chamber is used to increase the temperature of the inner layer of the jacket, and the fine water mist generated by the atomizing nozzle directly contacts the inner furnace wall of the jacket. Water vapor is generated, and the water is sprayed into the biomass fuel in the gasification air chamber...

specific Embodiment approach 3

[0014] Specific implementation mode three: as figure 1 As shown, the plurality of air chambers in this embodiment are composed of the first air chamber 9, the second air chamber 10, the third air chamber 11 and the fourth air chamber 12; the first air chamber 9, the second air chamber 10. The third air chamber 11 and the fourth air chamber 12 are arranged sequentially along the furnace 16 from the inlet end to the outlet end. Such setting can fully provide the air required for the combustion of syngas and semi-coke to the furnace. Other components and connections are the same as those in the first embodiment.

[0015] Specific implementation mode four: as figure 1 As shown, in this embodiment, a secondary air inlet 13 is provided at the rear of the boiler body 17, and the secondary air inlet 13 is used to provide the furnace 16 with the air required for combustion, which can further improve the combustion efficiency. Other compositions and connections are the same as those ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com