Air and steam gasification downdraft gasified combustion boiler with catalyst internally arranged

A water vapor and catalyst technology, applied in the field of combustion equipment, can solve problems such as black smoke, high dust content, and excessive tar accumulation, and achieve the effects of increasing energy density, low dust content, and reducing ash corrosion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

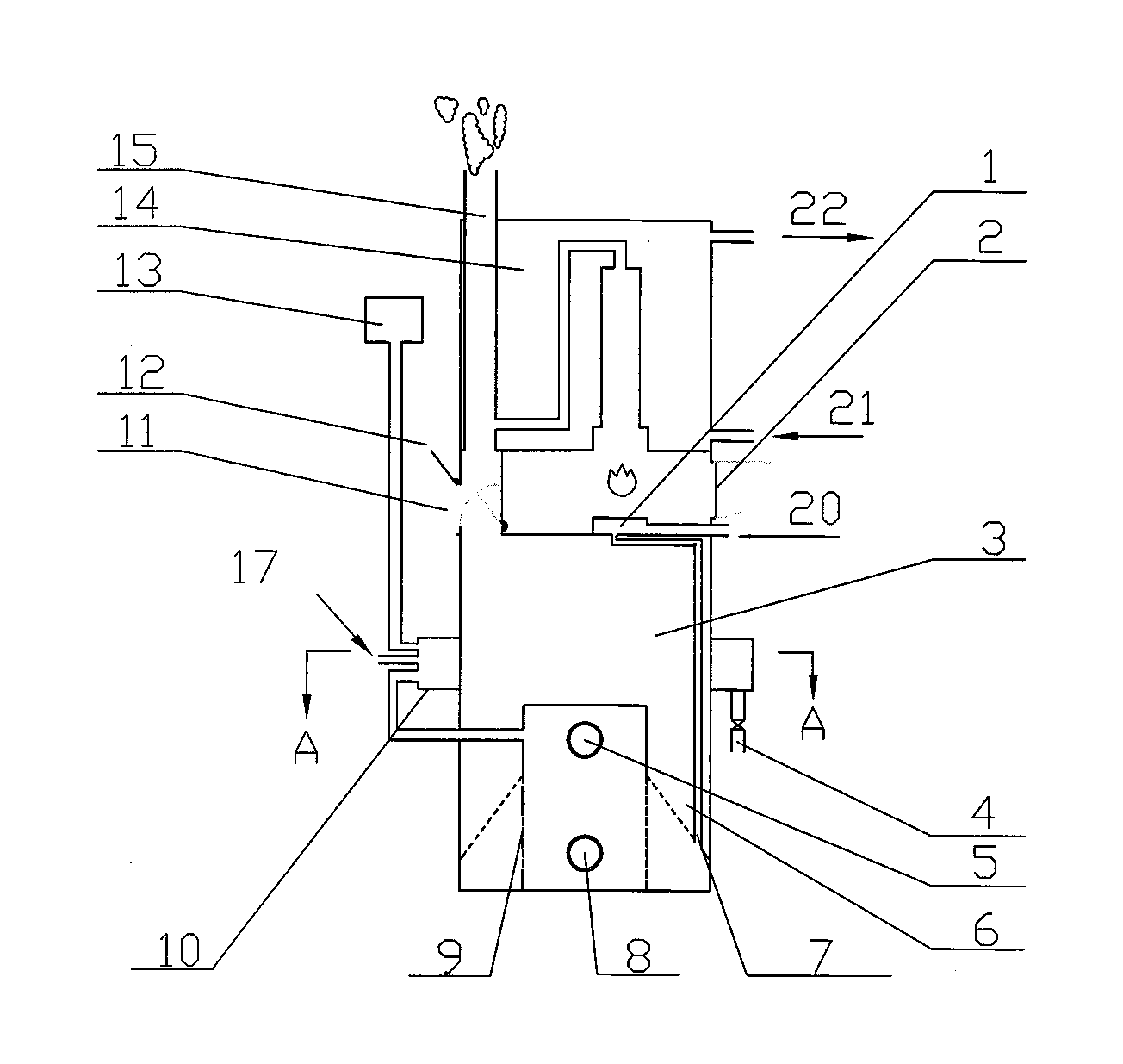

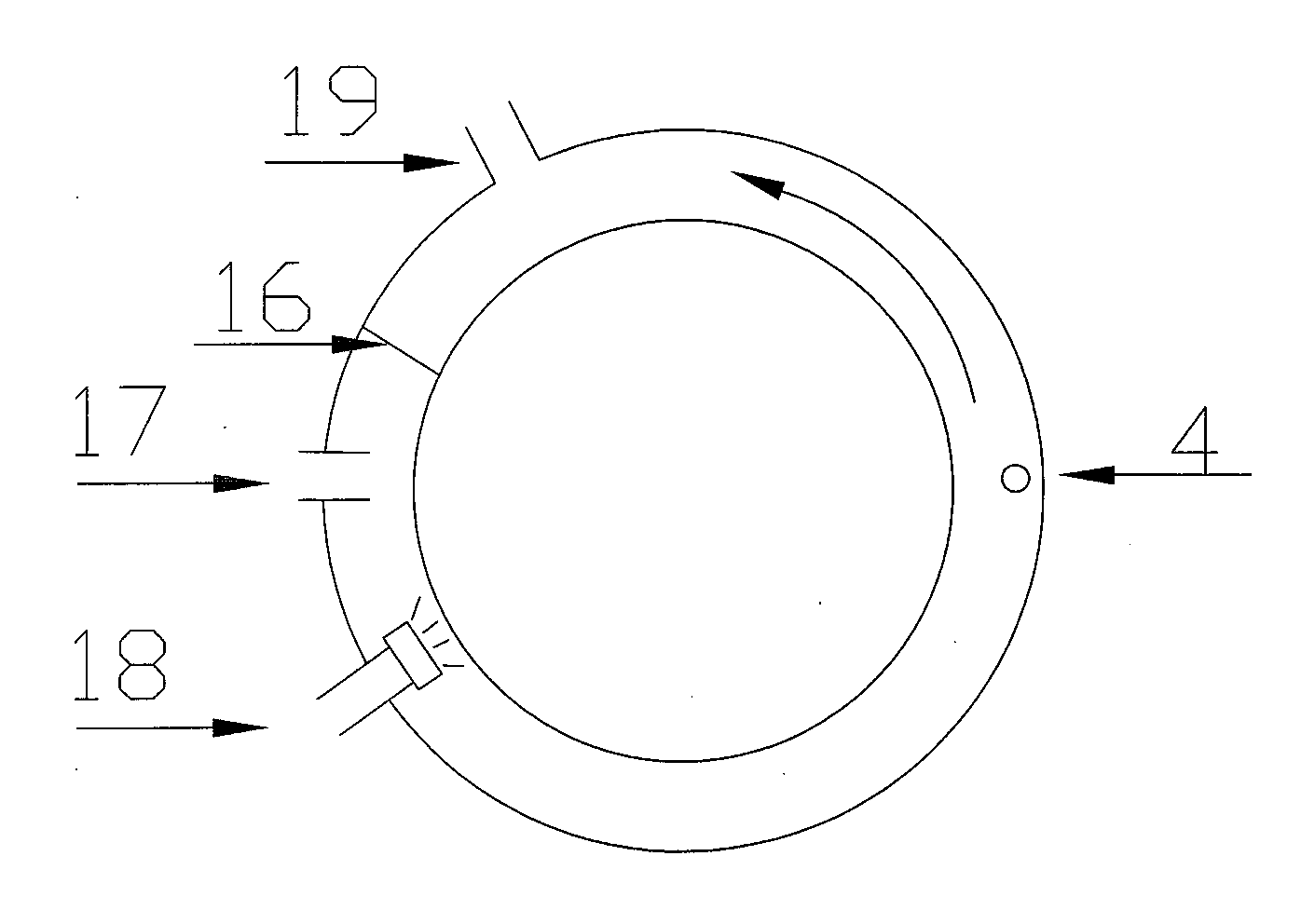

[0021] according to figure 1 and figure 2 The specific structure and working process of the present invention will be described in detail. According to the function, the present invention can be divided into three parts: a gasification furnace part, a gasification medium generation part and a combustion heat exchange part.

[0022] The gasification medium generation part includes a primary air inlet 17, an atomized water tank 13, a gasification medium mixing tank 10, and a drainage port 4, and its function is to generate a mixture of air and water vapor for gasification. The atomizing water tank 13 communicates with the gasification medium mixing box 10 through a conduit, and the gasification medium mixing box 10 communicates with the inner pipe 9 of the gasification furnace. The top of the furnace is provided with a partition 16, and the drain port 4 is arranged on the body of heater. The water in the atomizing water tank 13 enters the gasification medium mixing tank 10 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com