Method for first-pulse optimization in Q-switched solid-state lasers and Q-switched solid state laser

A solid-state laser and switching technology, applied in lasers, laser components, phonon exciters, etc., can solve problems such as manual optimization, different optimal parameter values, and manual intervention.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

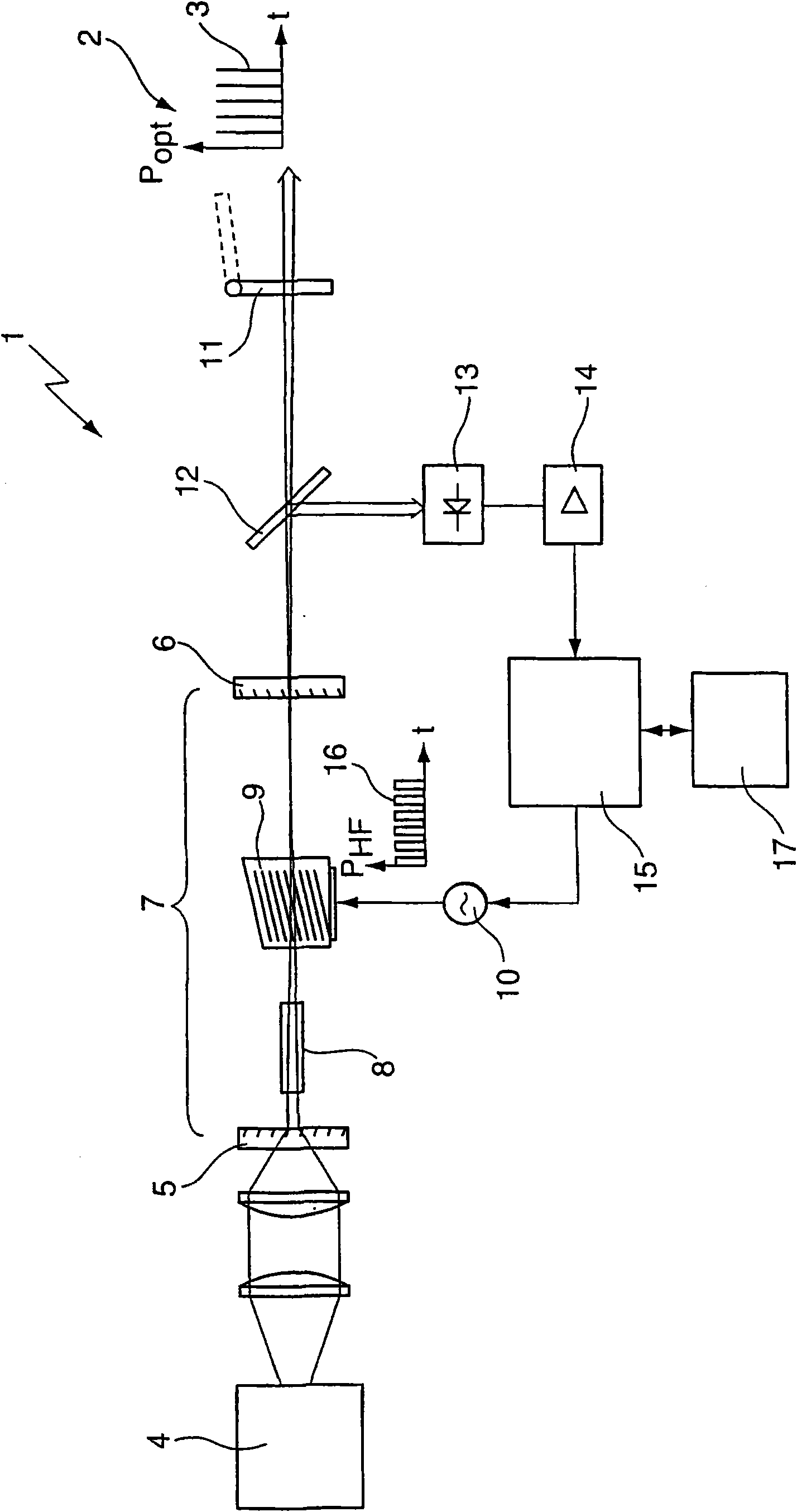

[0034] exist figure 1 The Q-switched solid-state laser 1 shown in is used to generate a pulse train 2 consisting of a number of individual pulses 3 with as constant a pulse energy as possible.

[0035] The solid-state laser 1 comprises a pump source 4, a laser resonator 7 and an HF driver 10, the laser resonator is defined by a highly reflective mirror 5 and an output coupling mirror 6 for the lasing light, in the laser resonator Housed in the cavity is a laser-active medium (laser medium) 8 pumped by a pump source 4 and an active Q-switch (Q-Switch) in the form of an acousto-optic modulator (AOM) 9 , the HF driver 10 for controlling the AOM 9 . Doped with rare earth ions (ND 3+ , Yb 3+ , Er 3+ ) base crystal (YAG, YVO 4 , YLF, GdVO 4 ) as the laser medium 8. These crystals are characterized by laser transitions with fluorescence lifetimes from tens of microseconds to milliseconds and are thus able to store in the Q-switched laser resonator 7 the energy pumped into the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com