Magnetic pole module of rotor, assembly method thereof and rotor

An assembly method and magnetic pole technology, applied in the field of magnetic poles and rotors, can solve the problems of lack of connection between magnetic steel and magnetic pole core, expansion of magnetic steel magnetic pole core, poor structural integrity, etc., to achieve long-term reliability and meet fixed Requirements, effect of guaranteeing long-term reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The magnetic pole modules of the rotor of the embodiment of the present invention, its assembly method and the rotor will be described in detail below with reference to the accompanying drawings.

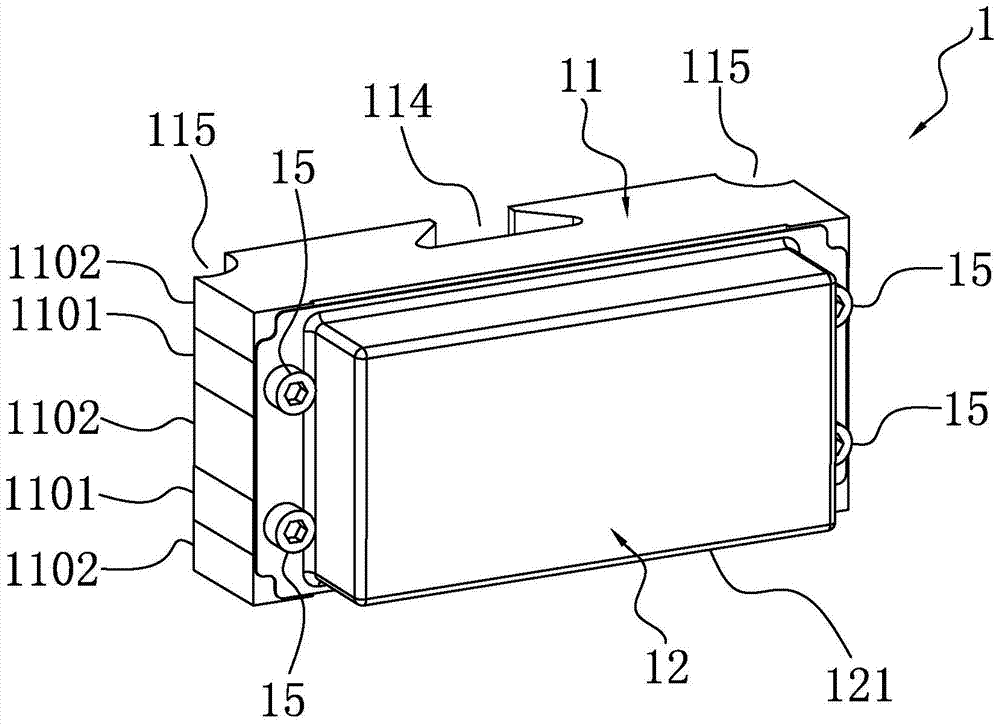

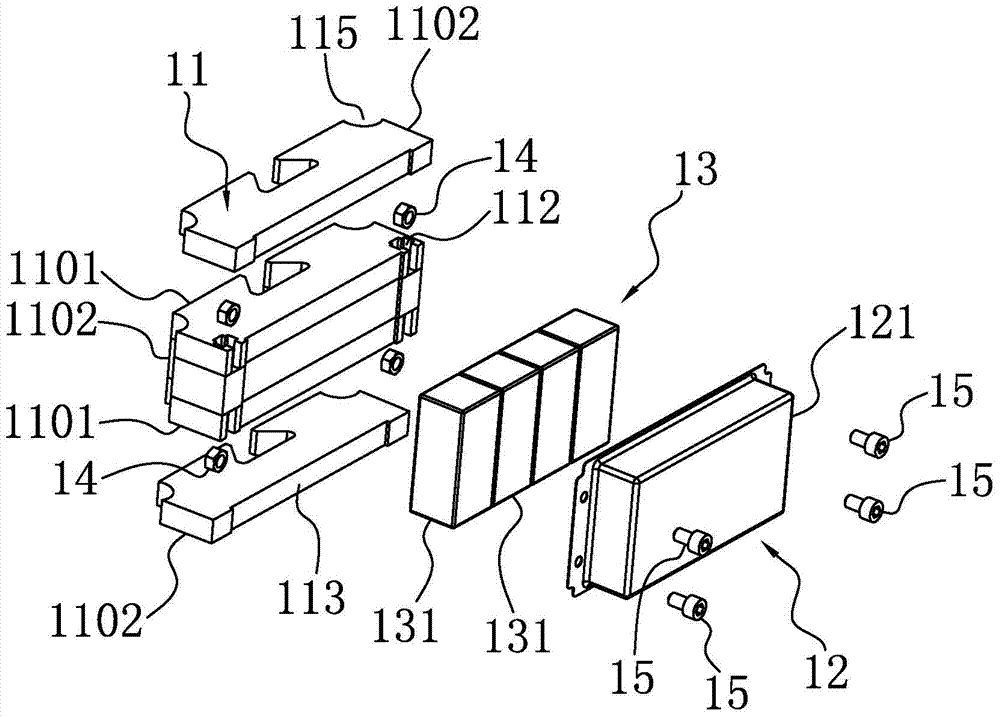

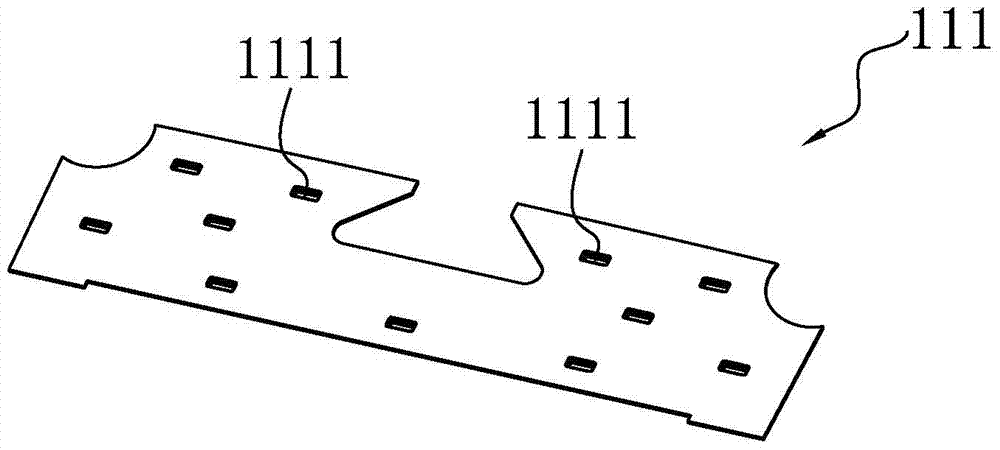

[0041] Such as figure 1 and figure 2 As shown, the magnetic pole module 1 of the rotor of the embodiment of the present invention includes a magnetic pole core 11, and a magnetic steel container 12 is connected to one side of the magnetic pole core 11 through a connecting piece, between the magnetic pole core 11 and the magnetic steel container 12 Magnetic steel 13 is provided.

[0042] The magnetic pole module 1 provided by the embodiment of the present invention uses the magnetic steel container 12 to buckle the magnetic steel 13 on one side of the magnetic pole core 11, and uses the connecting piece to connect the magnetic steel container 12 and the magnetic pole core 11 to form an integral module. Stable, the integrity is not affected by temperature, it is beneficial t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com