Air-returning decompression type high temperature hot blast stove capable of dedusting and removing smoke with calandria

A technology of high-temperature hot blast stove and air return duct, which is applied to air heaters, fluid heaters, lighting and heating equipment, etc., and can solve problems such as difficulty in stabilizing the outlet air temperature and flow rate, unreasonable structural design, and scattered smoke and dust, etc. Achieve the effects of improving frying quality, simple structure, and protecting the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

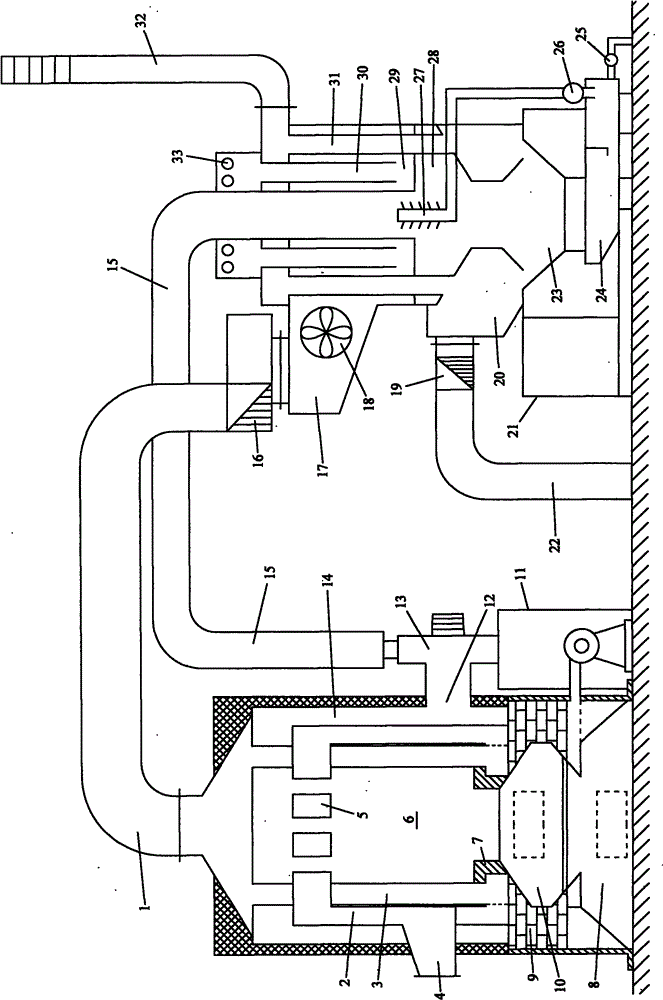

[0010] Example: see figure 1 , the invention includes a combustion furnace, a dust and smoke removal device and a waste heat recovery mechanism arranged on the dust and smoke removal device. Wherein the combustion chamber 10 of the combustion furnace is built with refractory bricks 9 around, and the temperature of the combustion chamber is very high, and the refractory bricks can protect the body of furnace and prolong its service life. The lower furnace 8 of the combustion furnace is used for removing ashes; the combustion chamber 10 is connected with the upper furnace The transition joint of 6 is provided with high-temperature-resistant separation ring 7, and the temperature at both transition joints is also very high, and high-temperature-resistant separation ring can be selected high-temperature steel or pottery clay to make for use, is used for protecting the wall body of inner layer hot air chamber 3, prolongs its service life. The upper hearth 6 of the combustion furna...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com