Patents

Literature

35results about How to "Improve frying quality" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

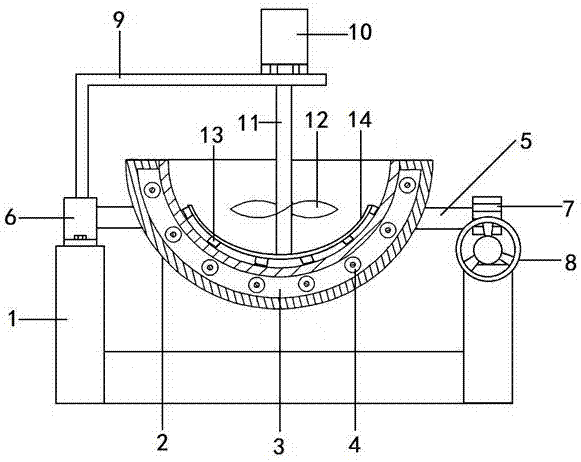

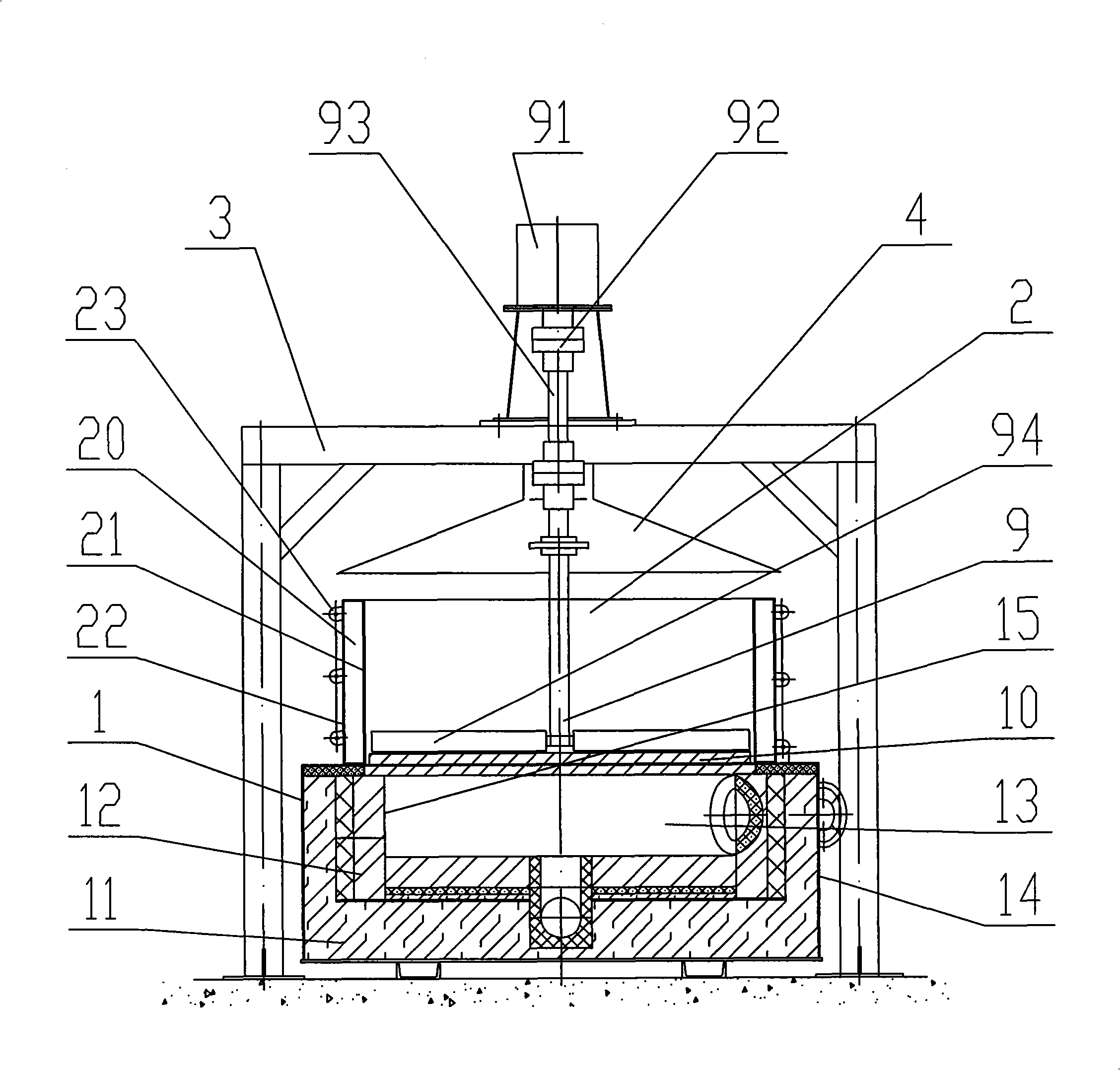

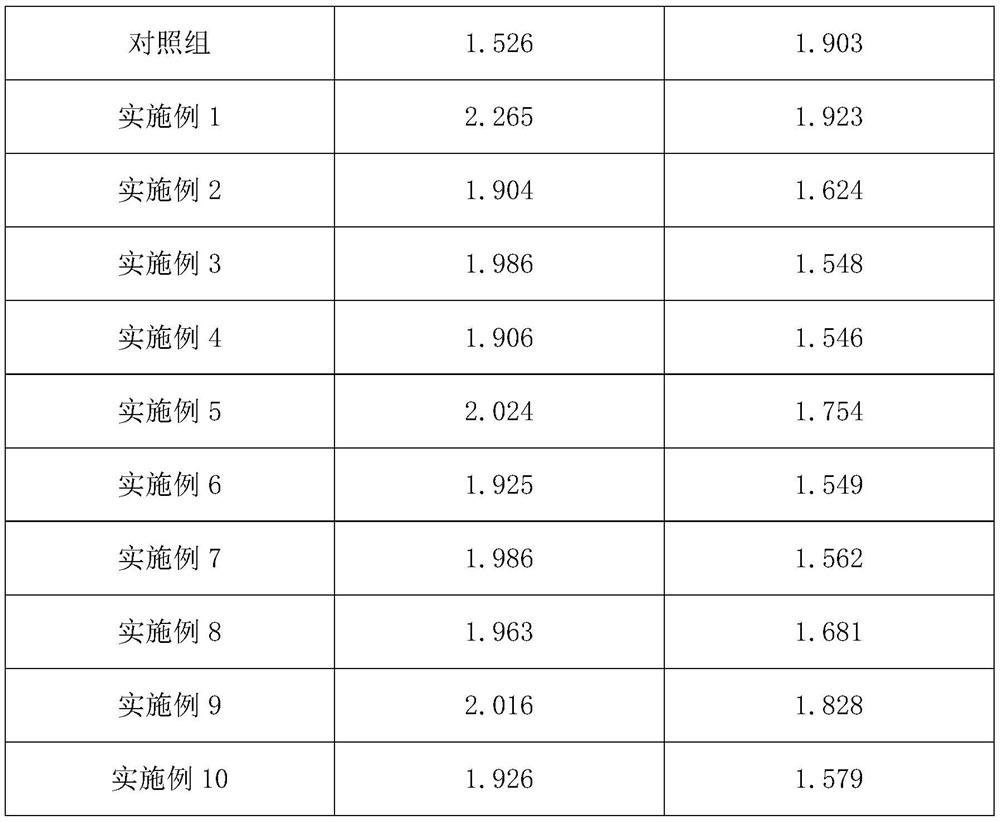

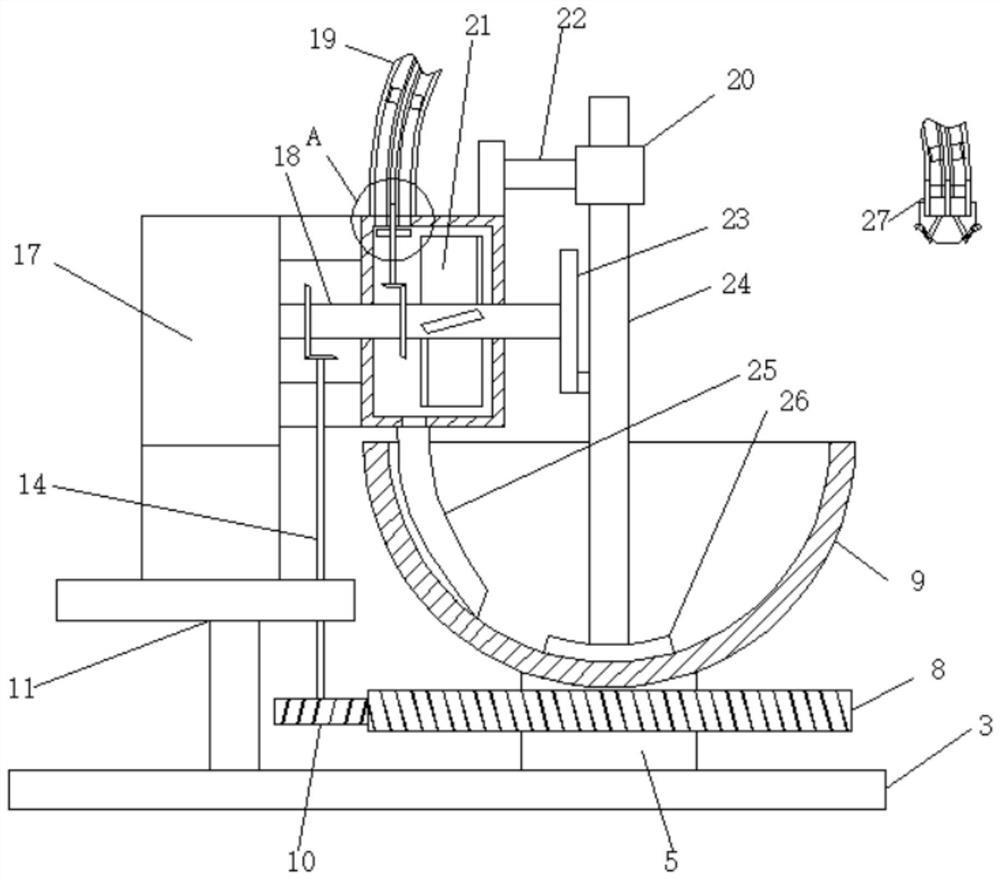

Herbal medicine roasting device

InactiveCN107411963AEvenly heatedStir wellPharmaceutical product form changeDomestic articlesElectric heatingTurbine

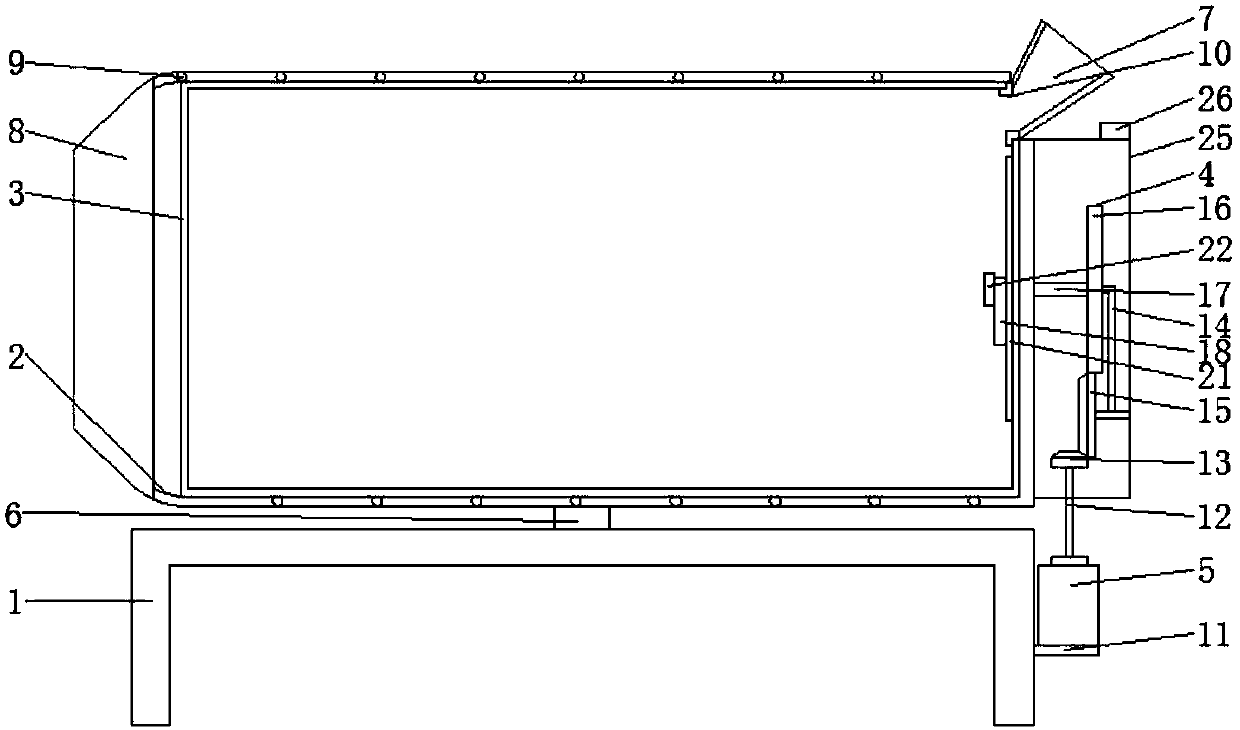

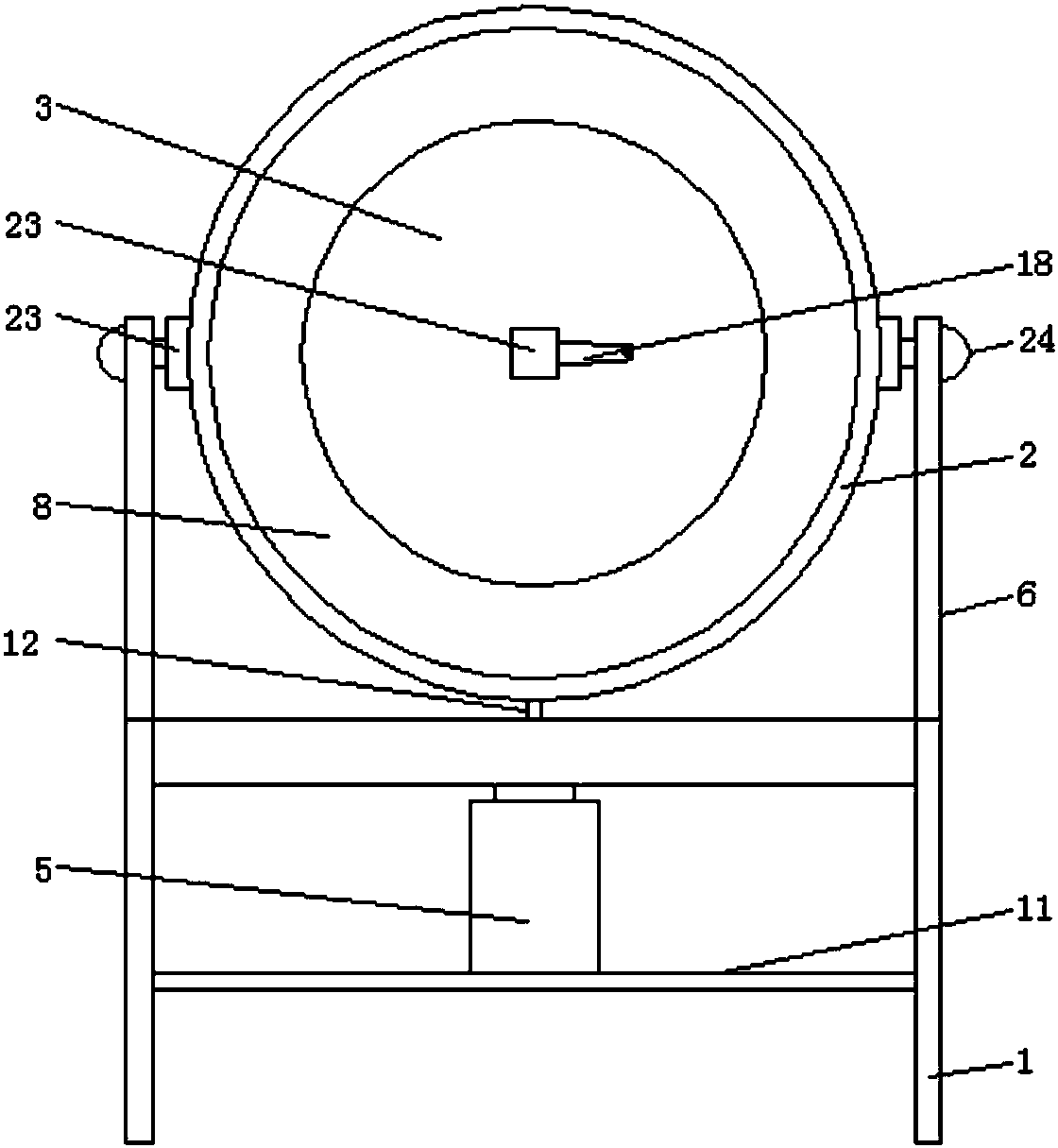

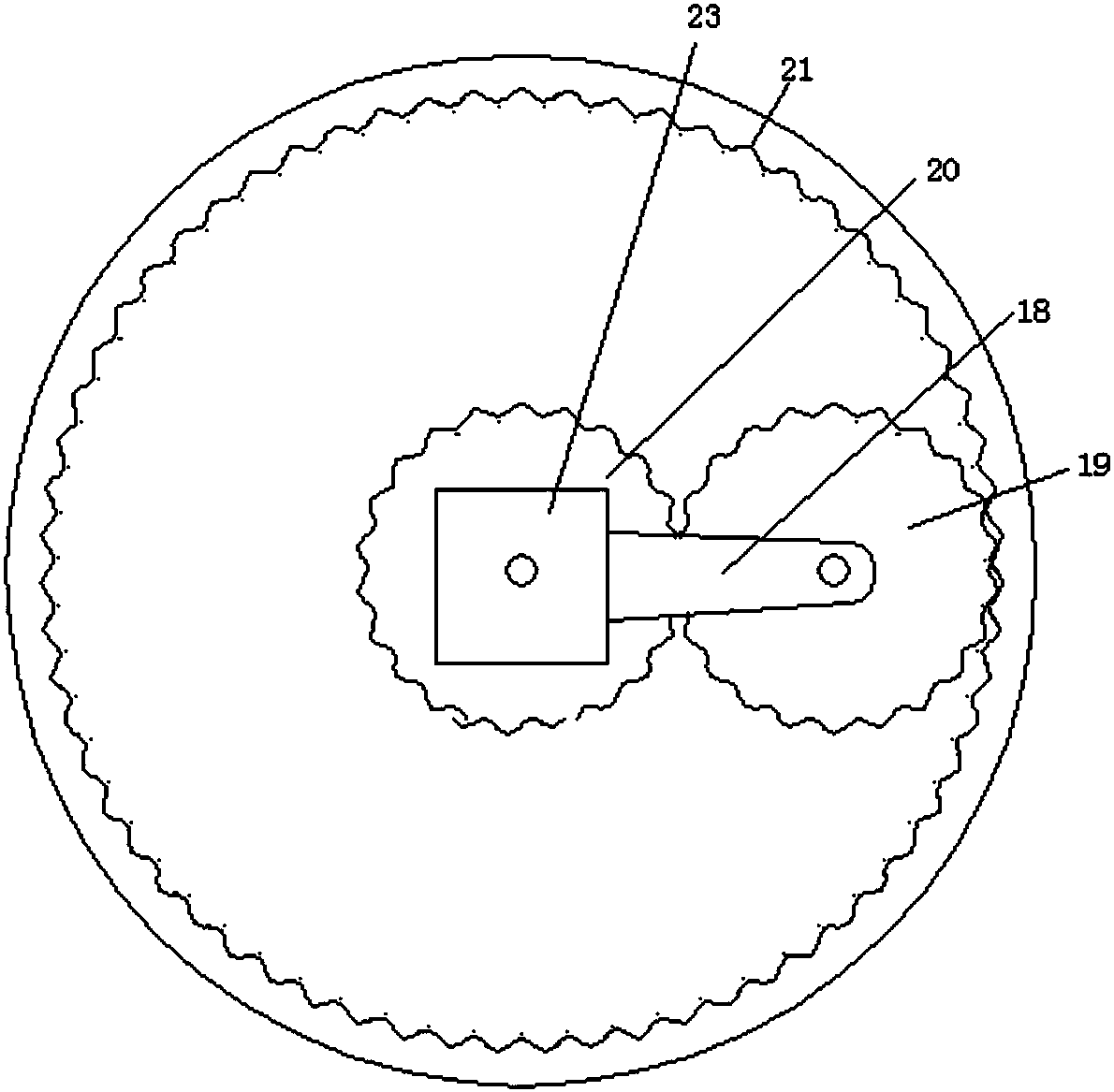

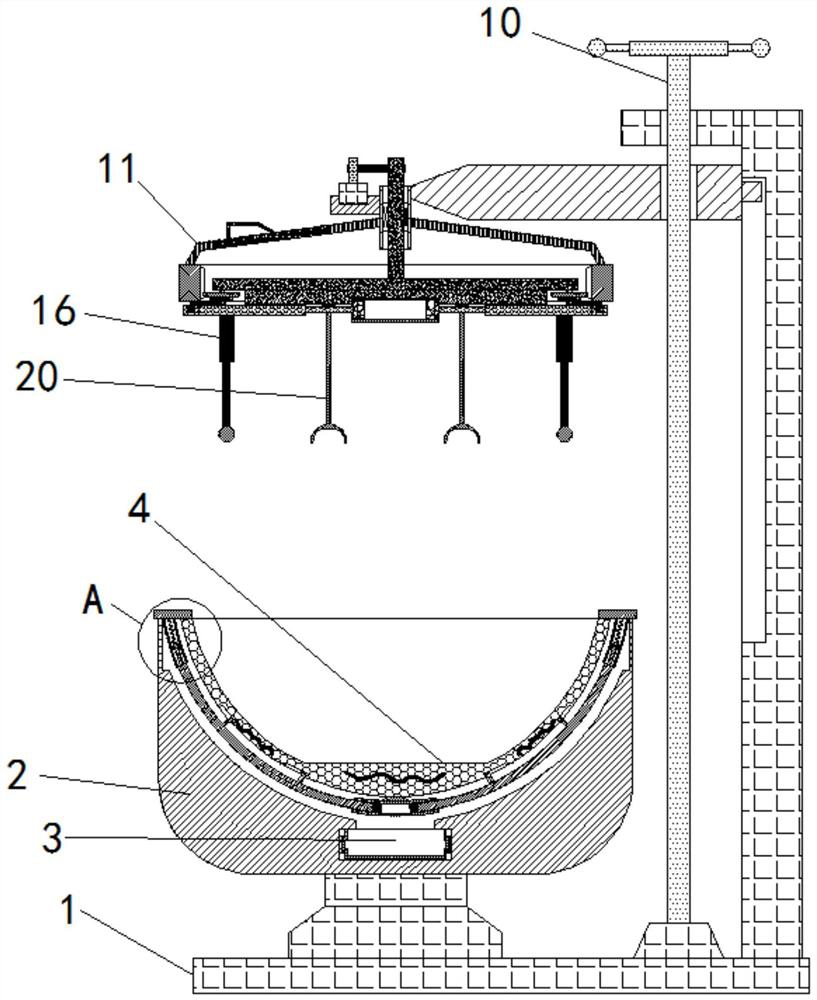

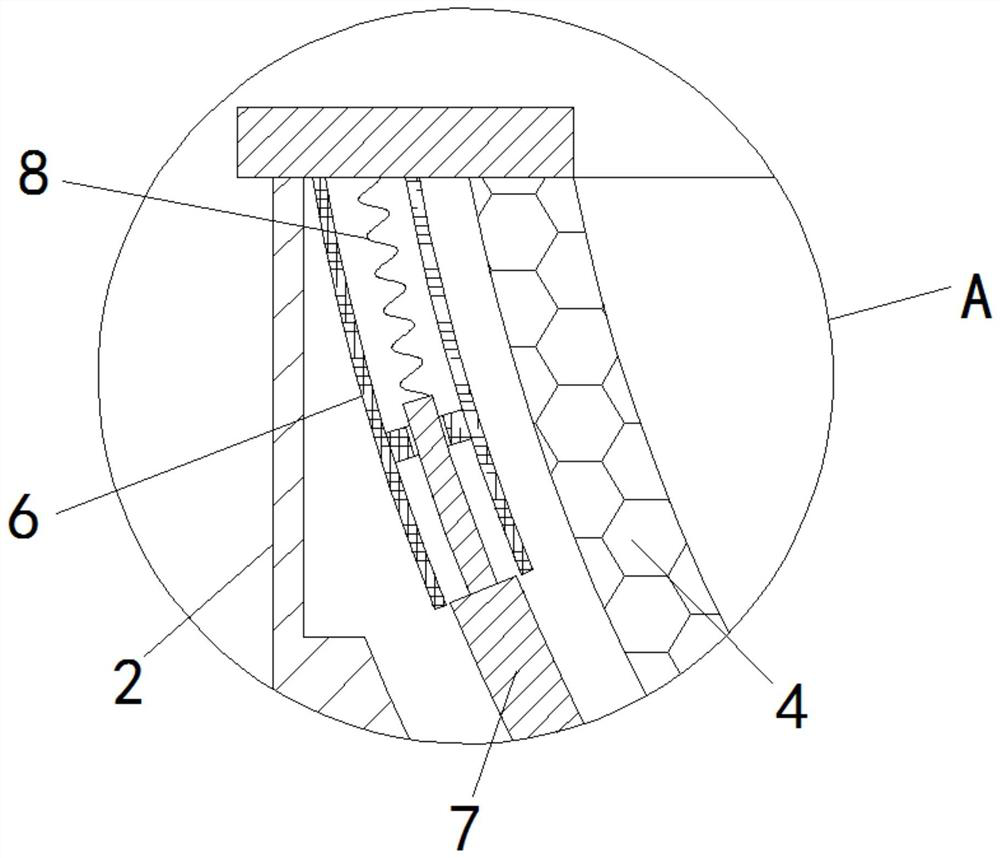

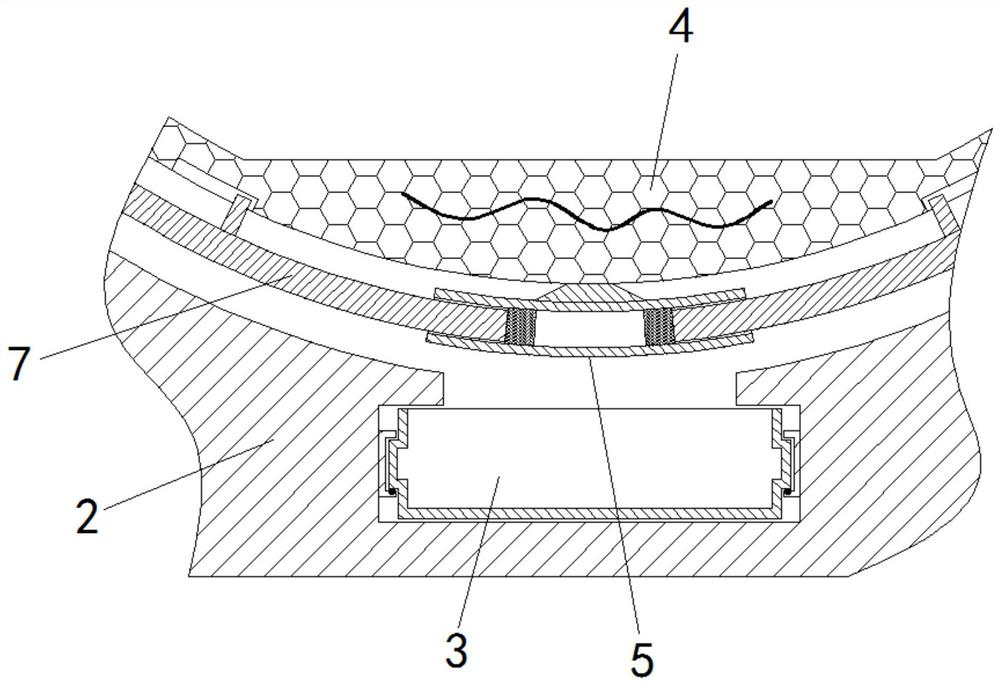

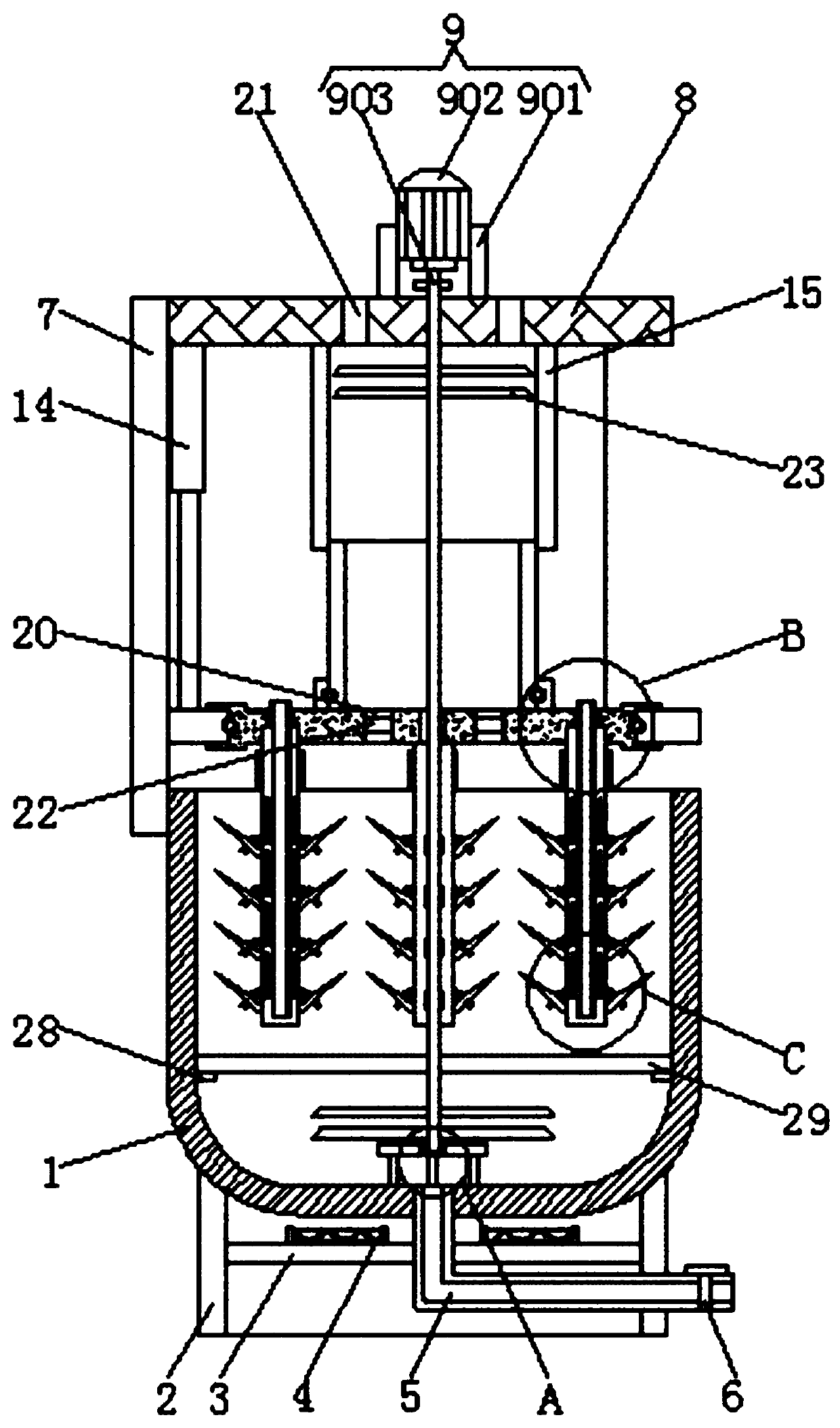

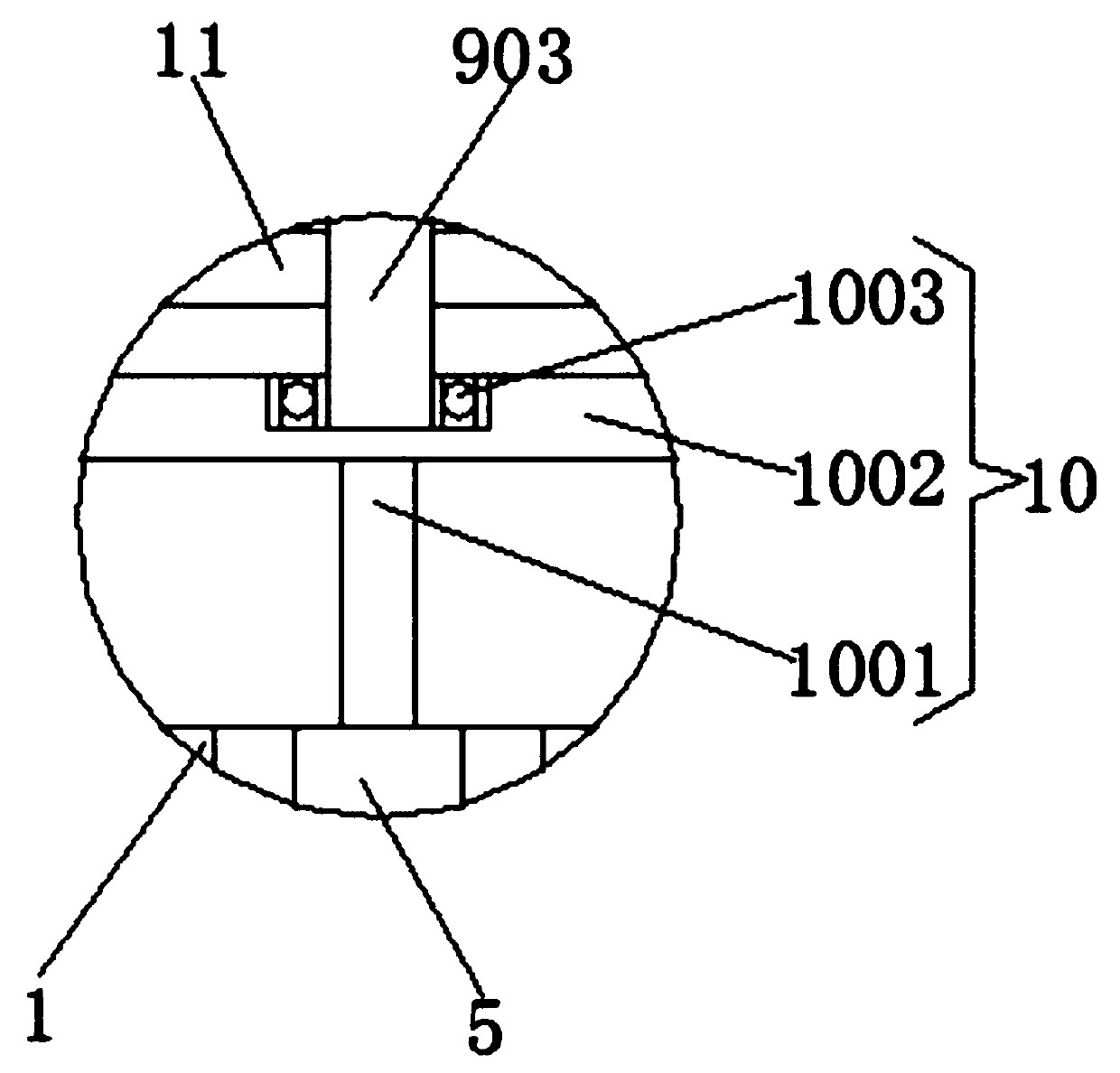

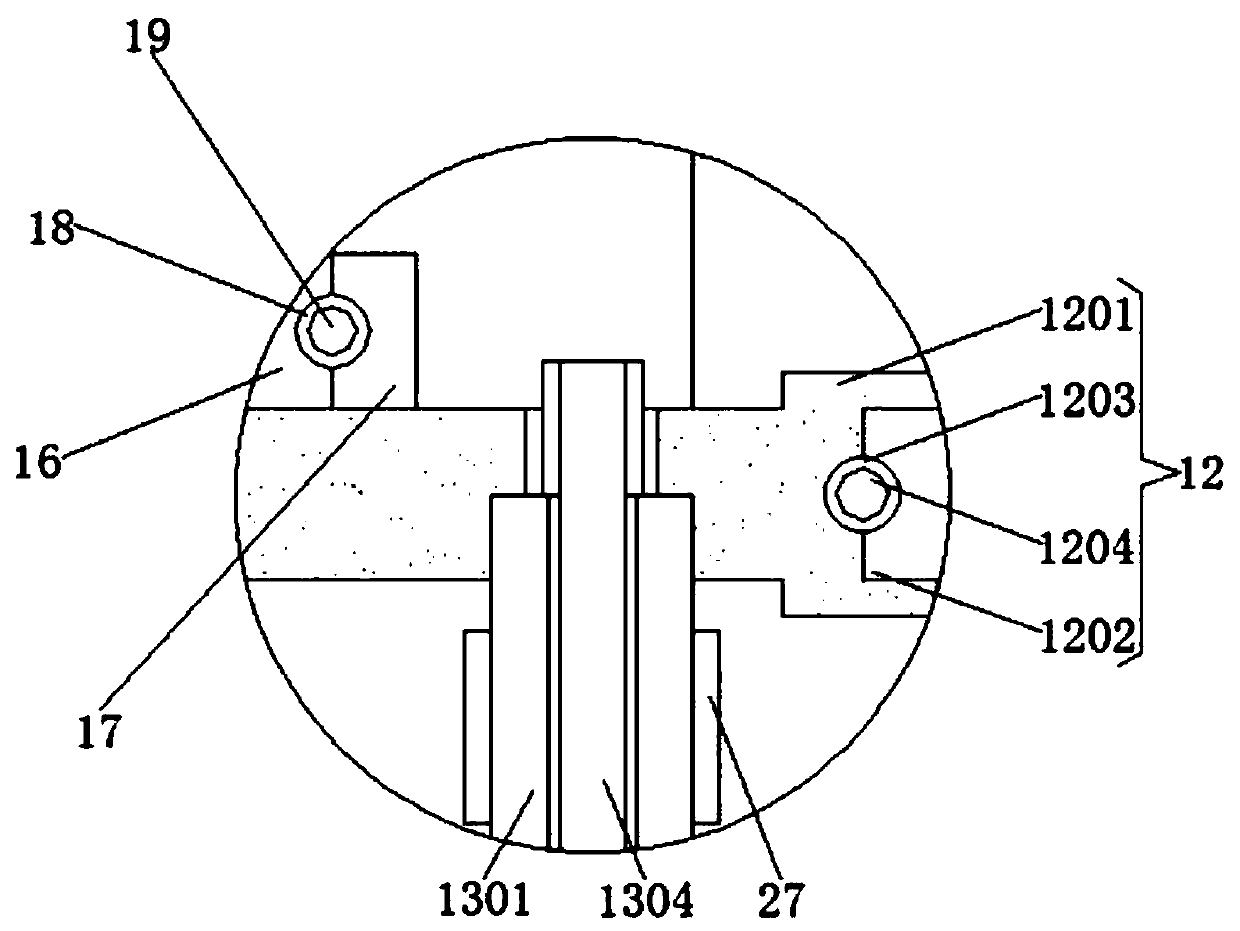

The invention discloses a herbal medicine roasting device which comprises a frame, a herbal medicine roasting pot and a stirring device. Two sides of the herbal medicine roasting pot are rotatably mounted on the frame through horizontally fixed rotating shafts, the stirring device is arranged above the center of the herbal medicine roasting pot, stirring blades are arranged in the middle of a stirring shaft of the stirring device, an arc-shaped stirring rod is arranged at one end of the stirring shaft, a scraper is arranged between the arc-shaped stirring rod and the herbal medicine roasting pot, the herbal medicine roasting pot is provided with an interlayer, an electric heating tube is arranged in the interlayer in a surrounding manner, a turbine fixedly sleeves one end of the rotating shaft, a worm in meshing transmission with the turbine is arranged on the frame, and a turntable is arranged at the end of the worm. By the aid of the interlayer and the electric heating tube in the interlayer, the whole herbal medicine roasting pot is uniformly heated and matched with the stirring device with the arc-shaped stirring rod and the stirring blades, so that medicinal materials can be all-dimensionally stirred and uniformly heated, and roasting quality is improved. After roasting, the herbal medicine roasting pot can be automatically inclined to realize discharging only by turning the turntable, and the herbal medicine roasting device is efficient and convenient.

Owner:赵爱

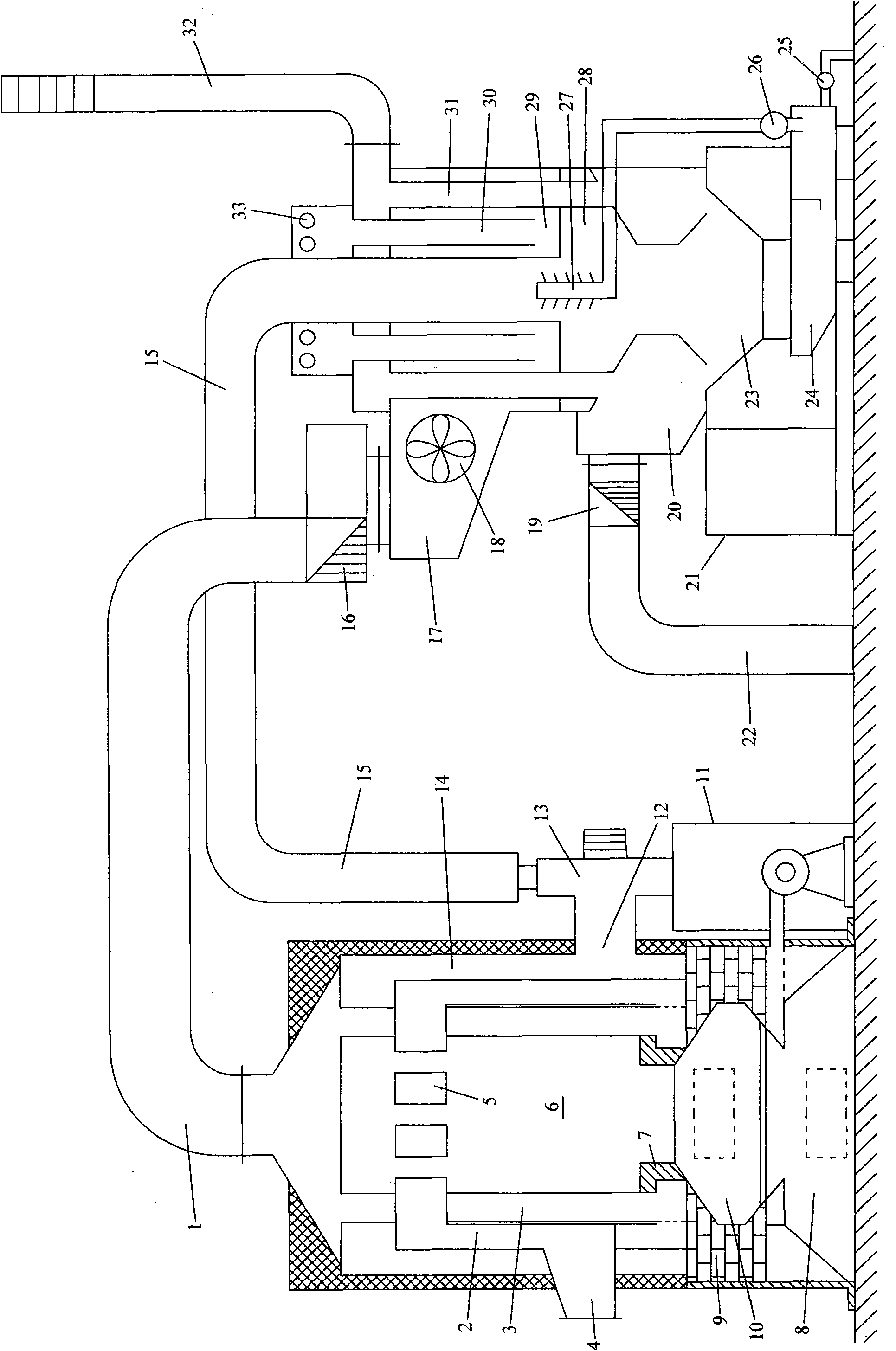

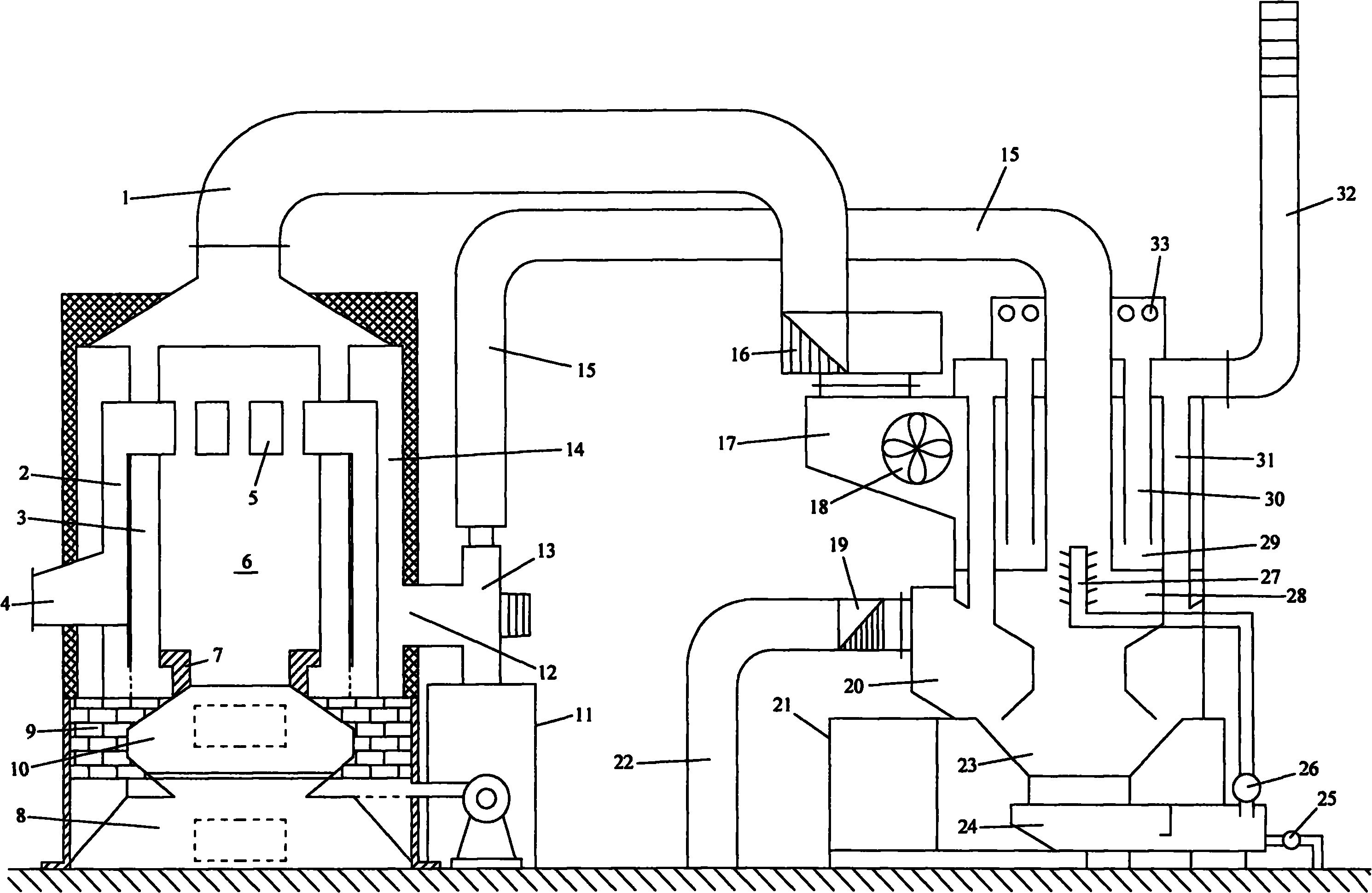

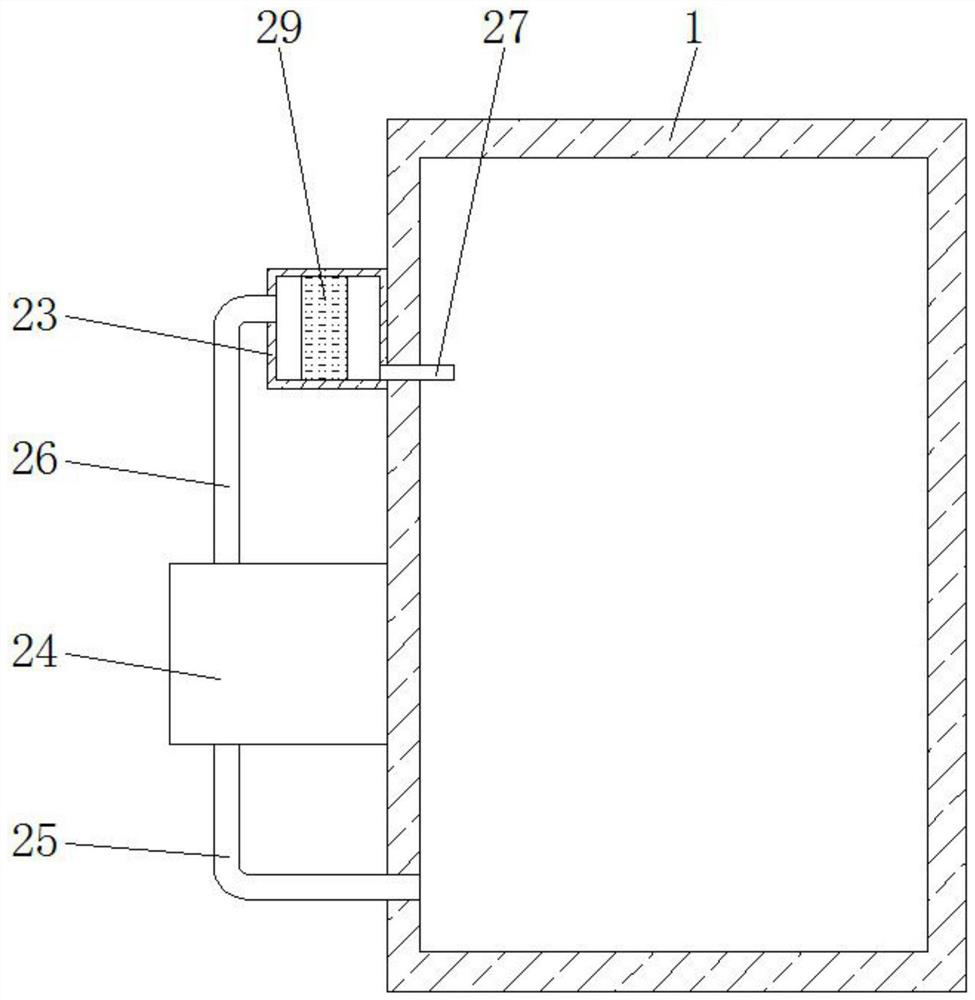

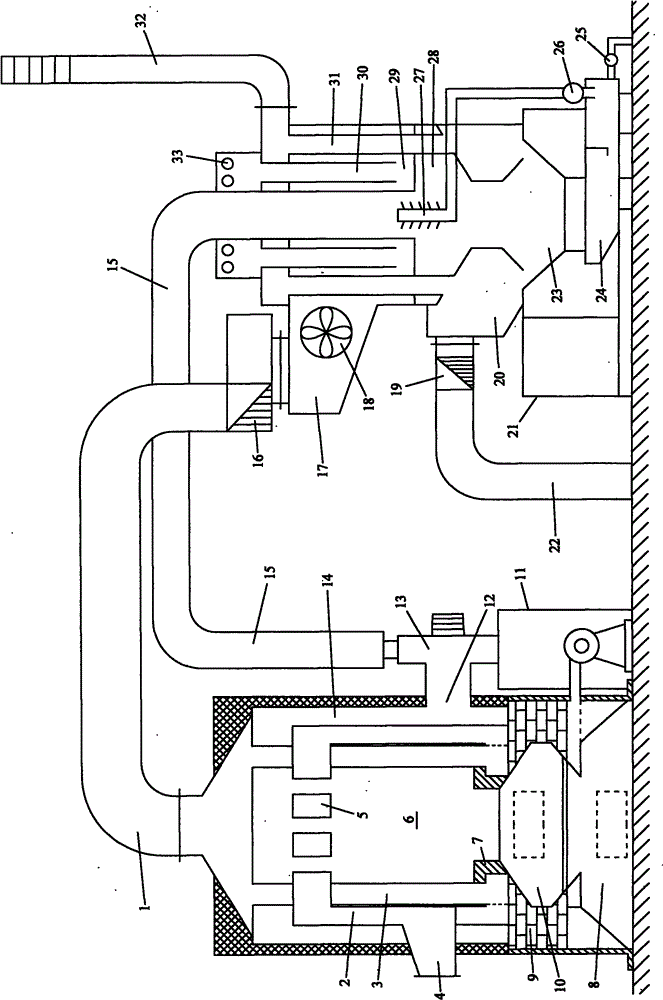

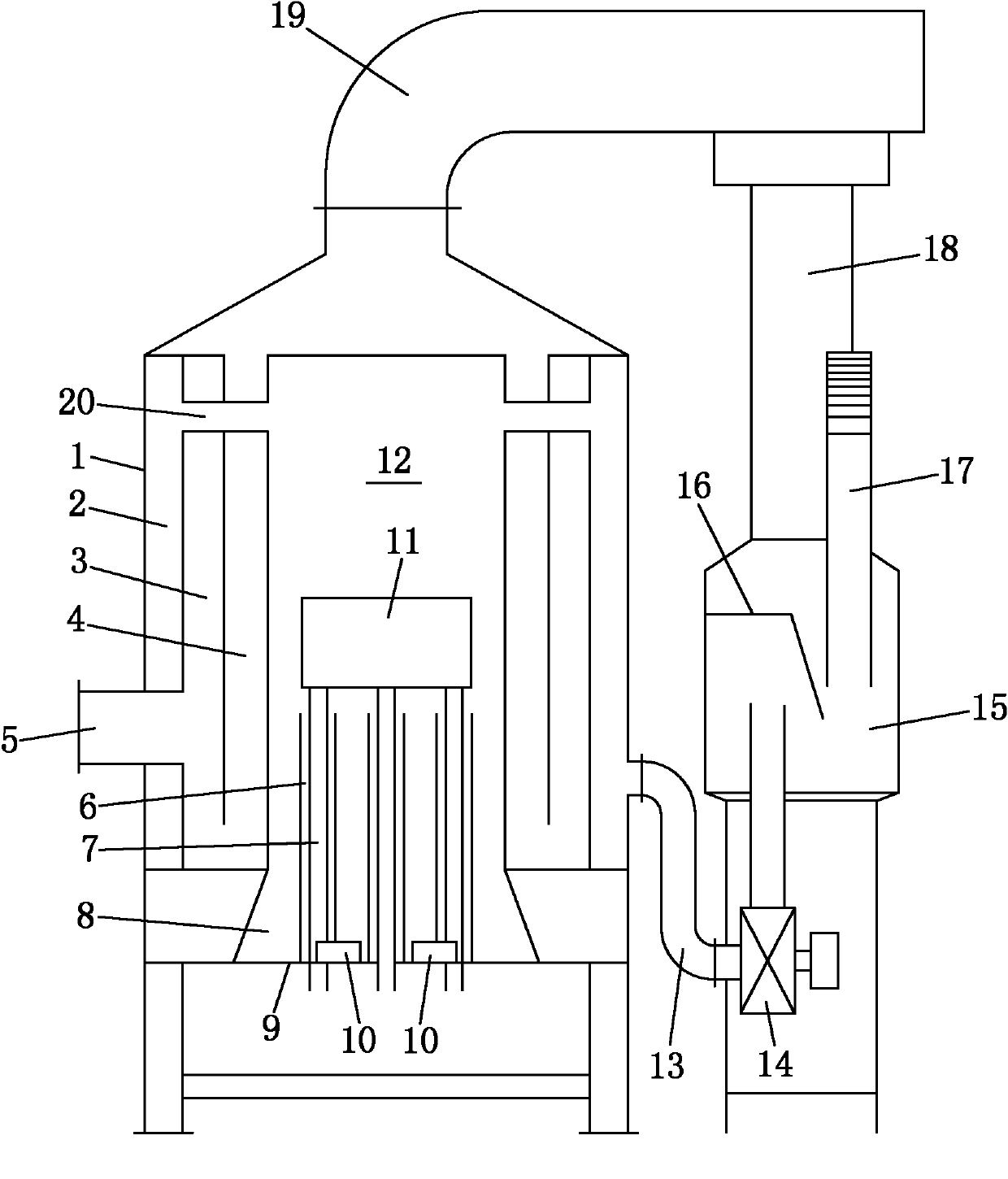

Air-returning decompressing high temperature hot blast stove capable of dedusting and removing smoke with calandria

InactiveCN101897363AReduce pollutionImprove protectionPre-extraction tea treatmentCombustionFresh air

The invention provides an air-returning decompressing high temperature hot blast stove capable of dedusting and removing smoke with a calandria. A waste heat return aircourse is arranged on an upper hearth of a combustion furnace, the waste heat return aircourse is communicated with a hot-blast air cavity in an inlayer of the upper hearth and is communicated with a hot-blast air outlet by a hot-blast air cavity in an outer layer; a smoke dust cavity of the upper hearth is communicated with a smoke dust channel through a smoke dust channel port and a draught fan, and the smoke dust channel is communicated with a dedusting and smoke-removing device; and a waste heat recovering mechanism comprises a fresh air inlet arranged on the dedusting and smoke-removing device, wherein the fresh air inlet is communicated with a waste heat cavity in the dedusting and smoke removing device through a fresh air cavity in the dedusting and smoke removing device, one side of the waste heat cavity is provided with a waste heat outlet, a waste heat blower is arranged on the waste heat outlet, and the waste heat blower is communicated with a waste heat return aircourse. The invention reduces pollution of smoke dust to atmosphere and is beneficial to protecting environment; after the fresh air enters, the fresh air has the constant temperature after heating for multiple times and has constant air-out flow, thereby improving effects of firing and green-removing of tea leaves, and being beneficial to improve firing quality of the tea leaves.

Owner:浙江绿峰机械有限公司

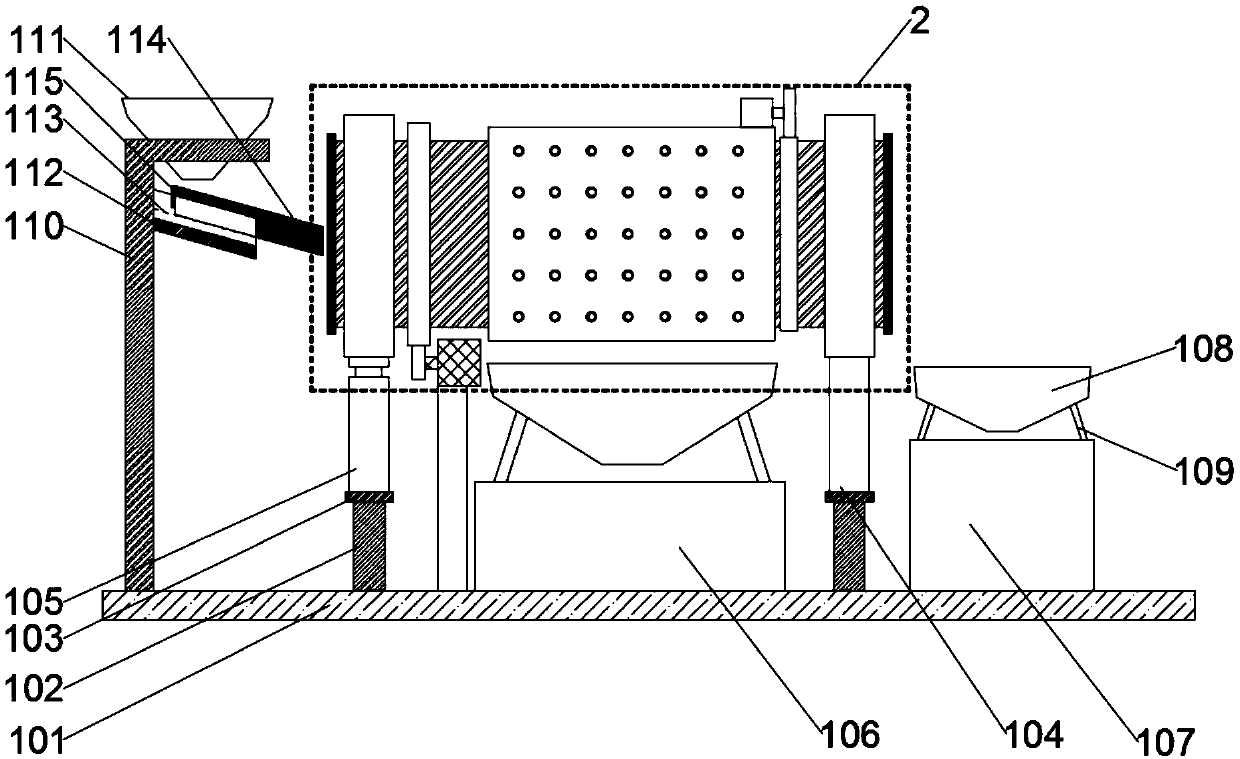

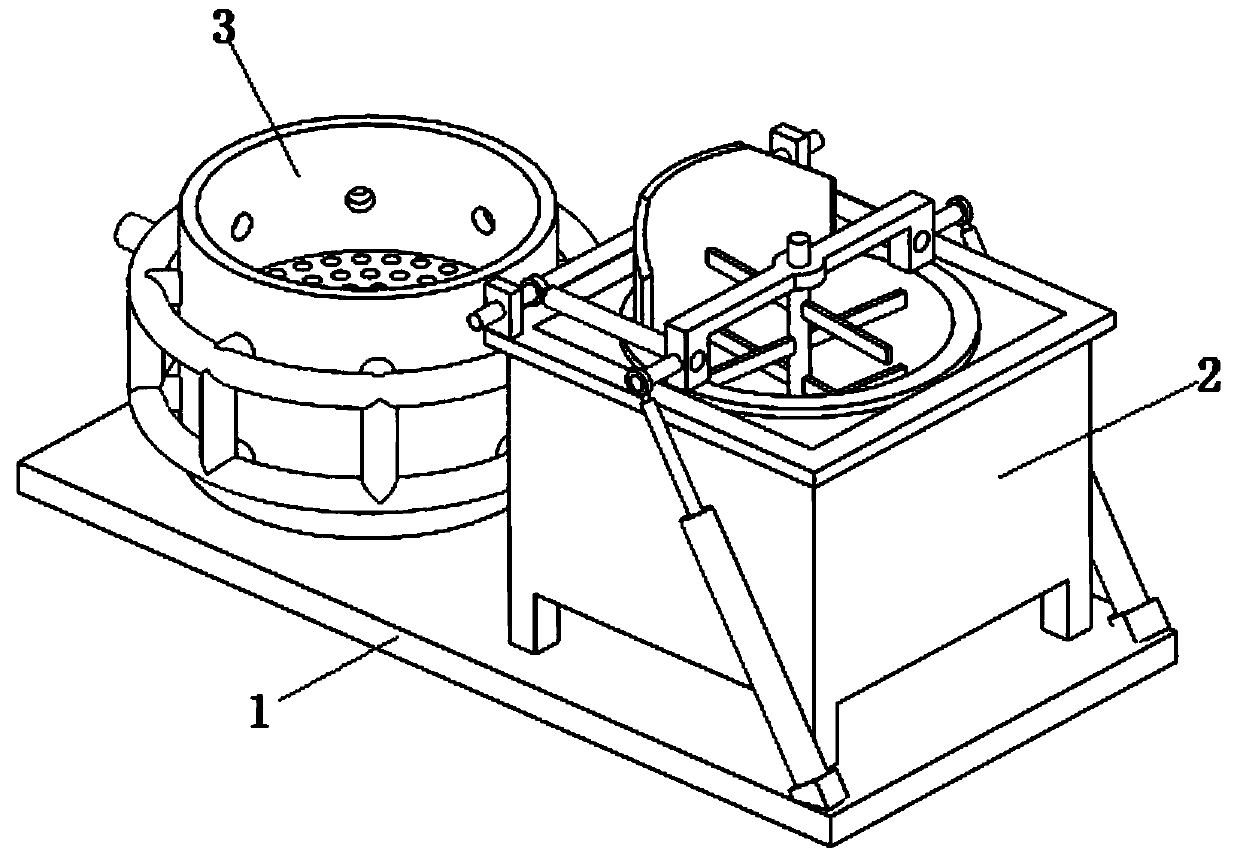

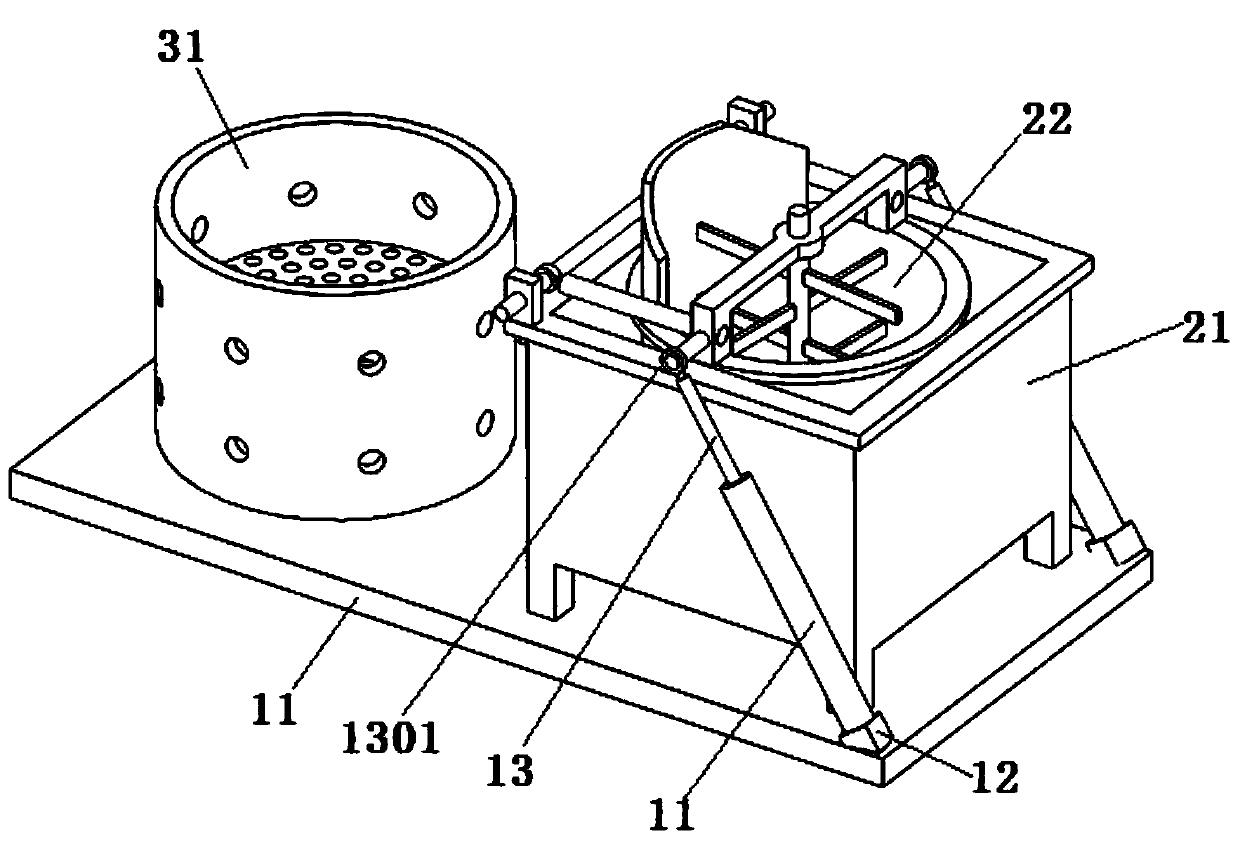

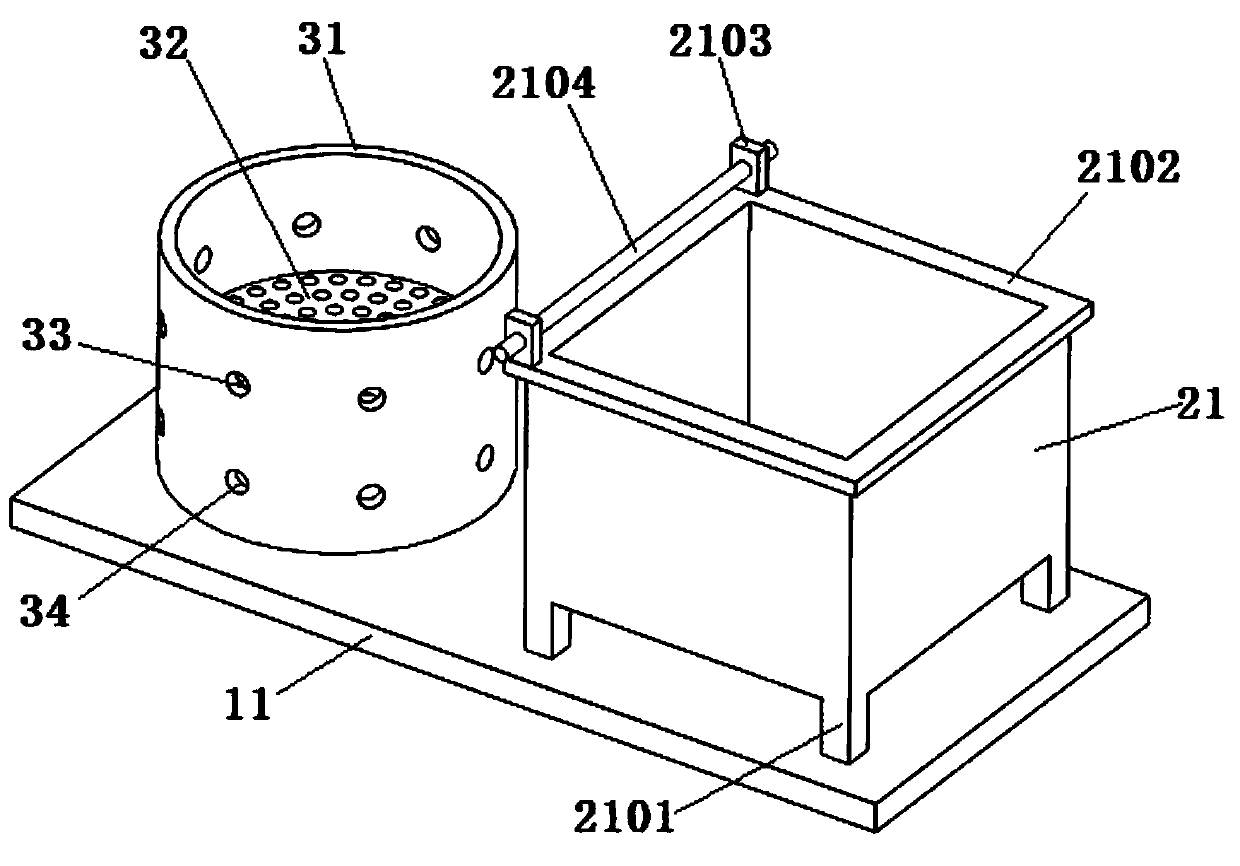

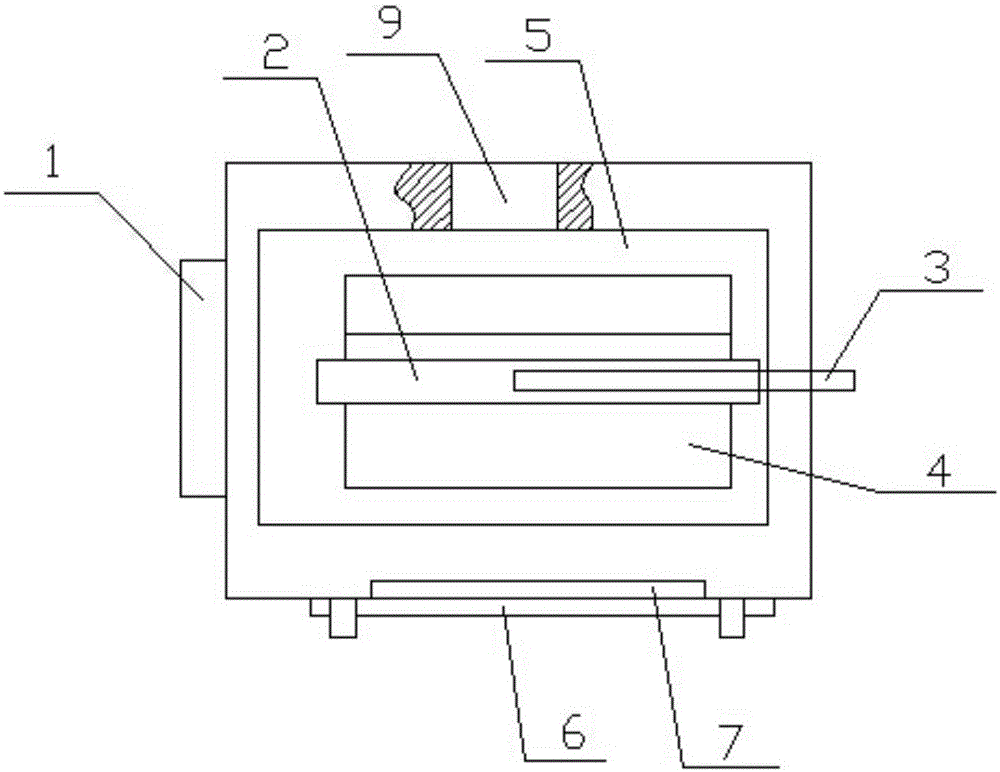

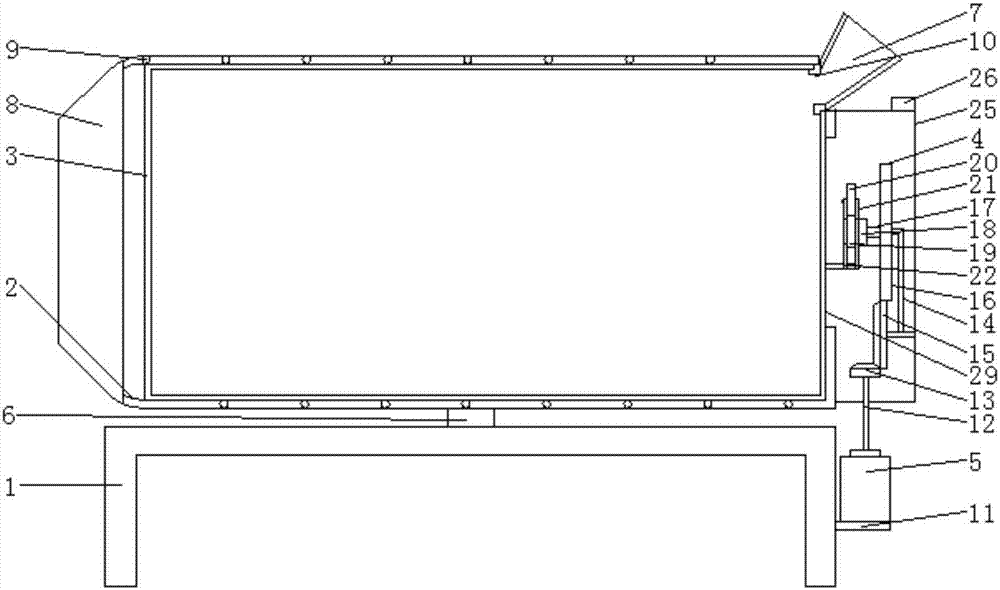

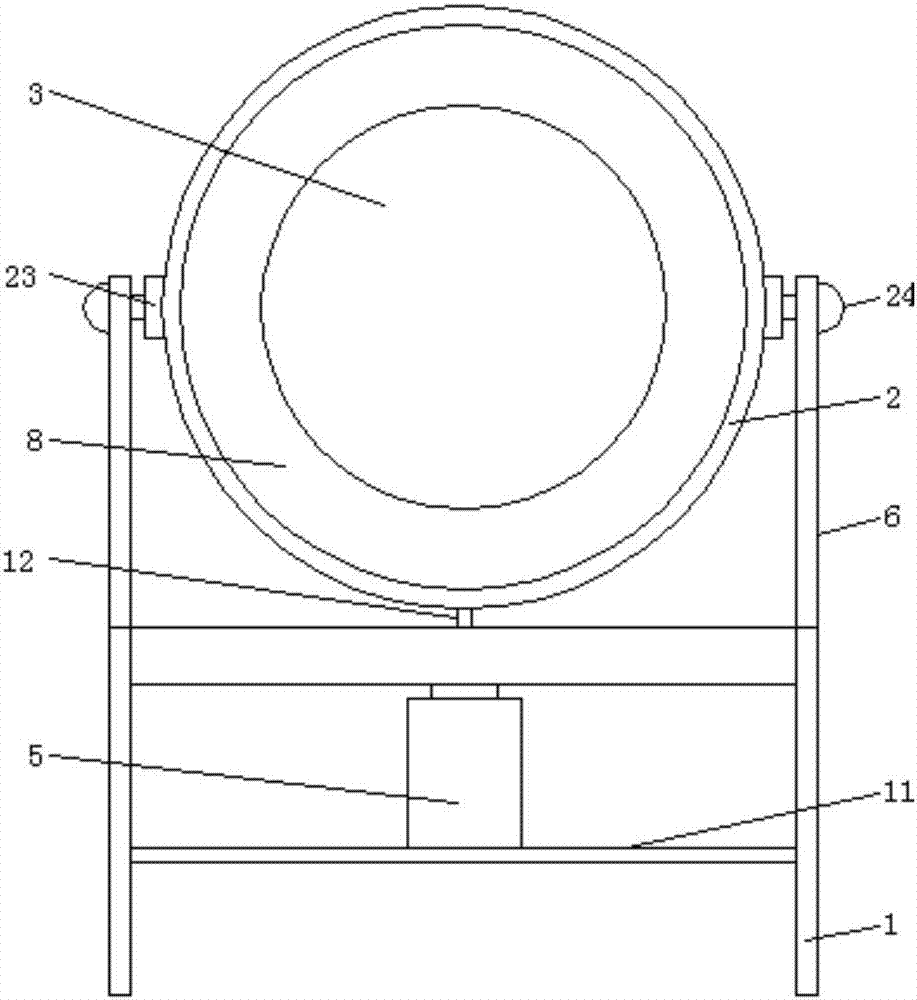

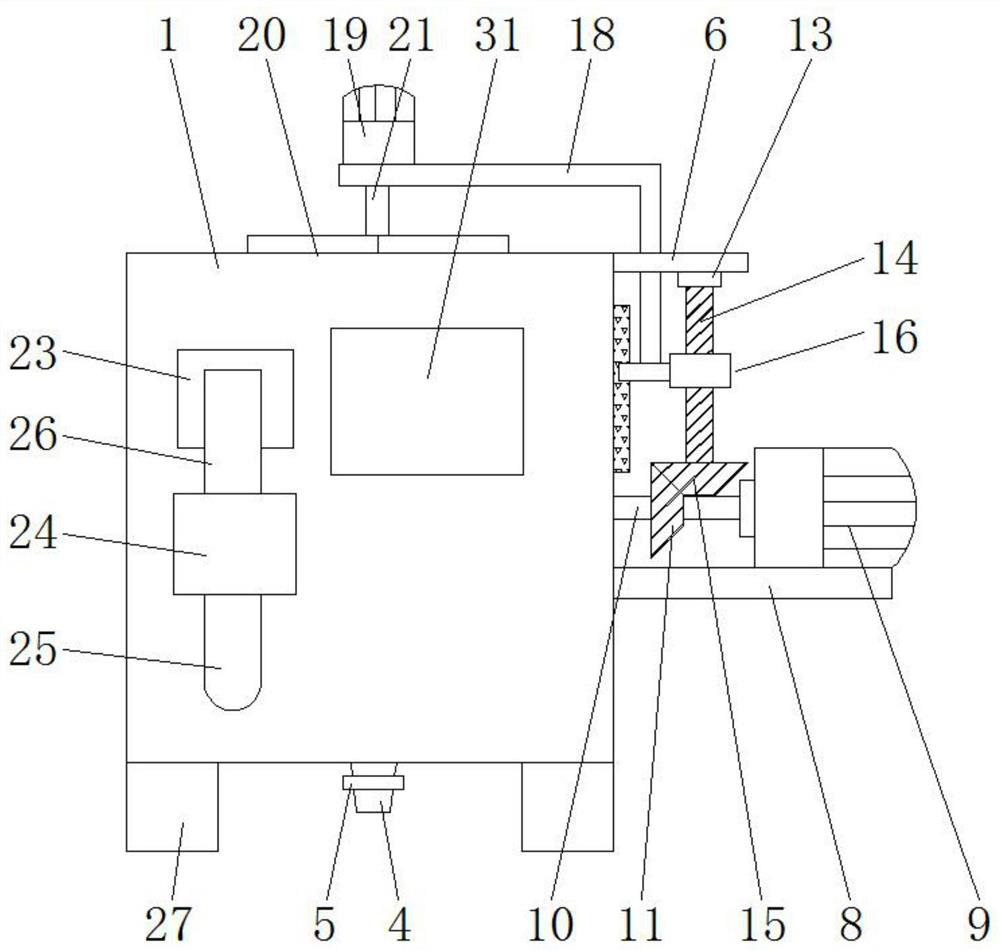

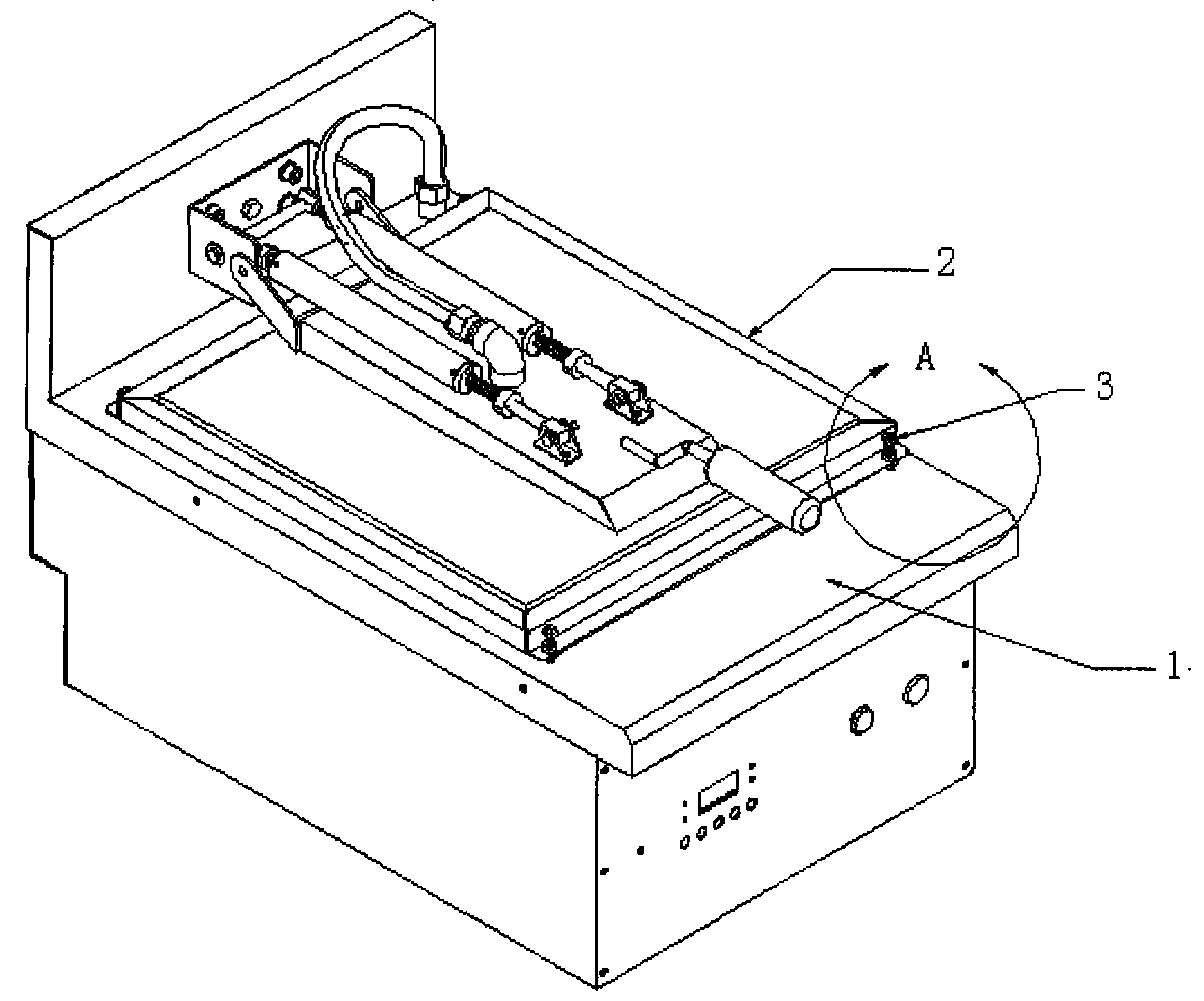

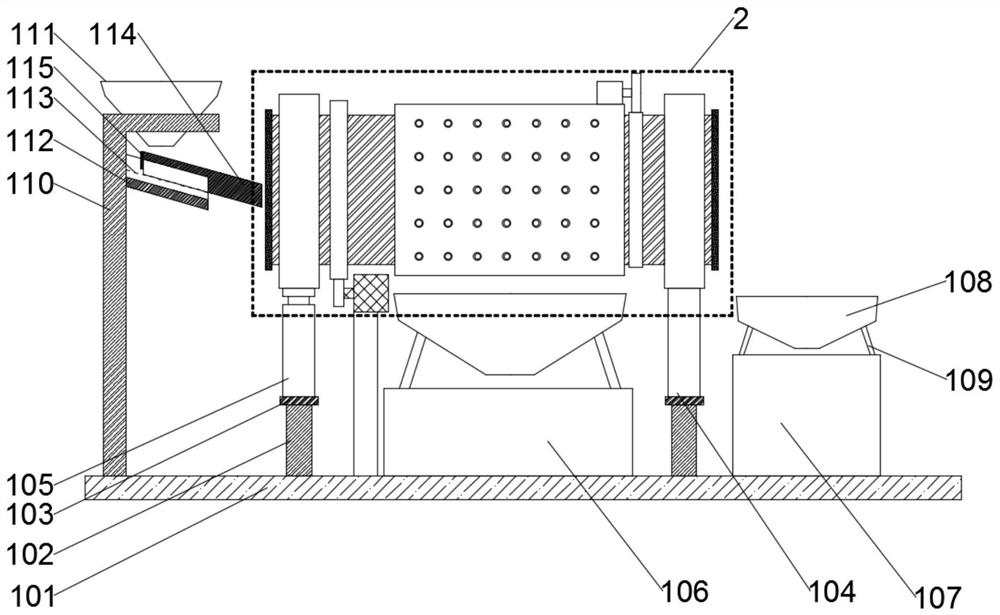

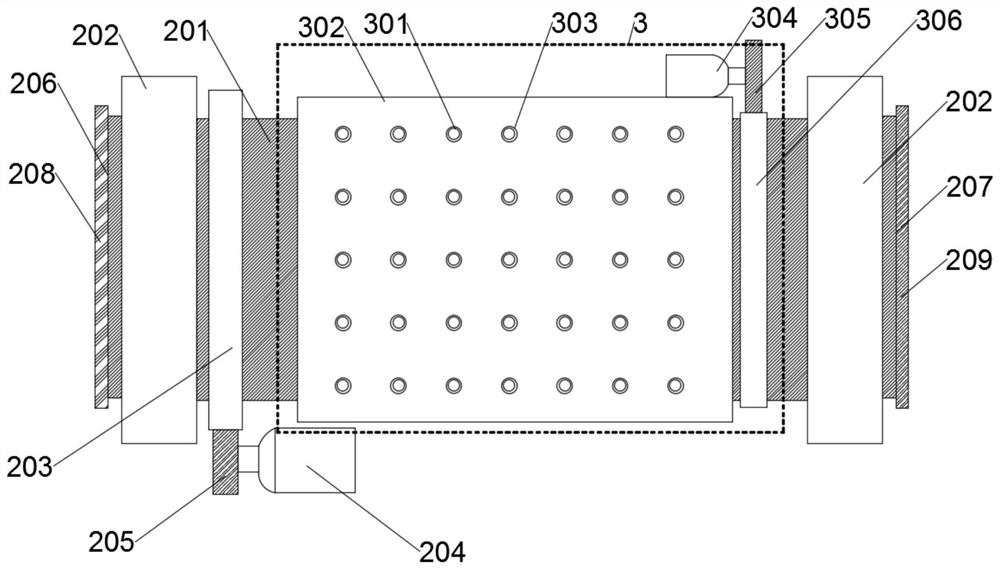

Tea frying device with screening function

ActiveCN109675787AFried evenlyNot easy to go too farSievingPre-extraction tea treatmentSoftware engineeringTea leaf

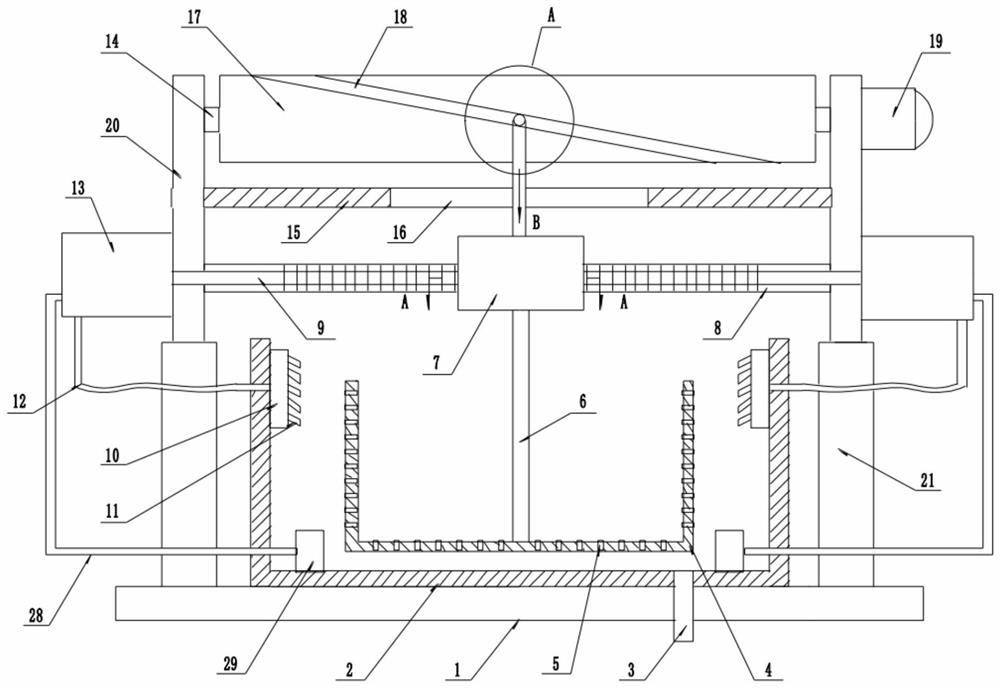

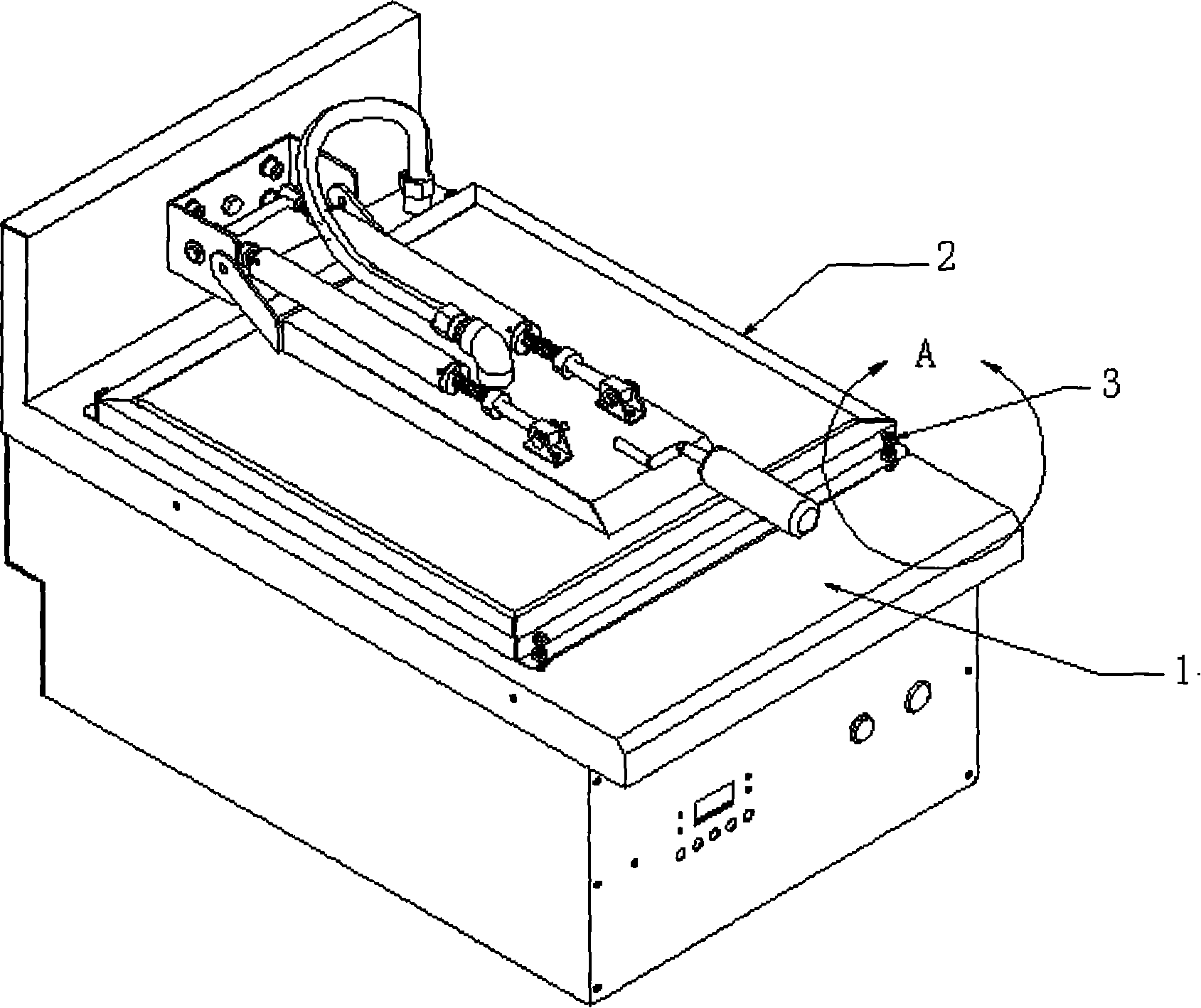

The invention discloses a tea frying device with a screening function. The tea frying device with the screening function comprises an installation structure. The installation structure is provided with a stir-frying assembly and a screening assembly. The installation structure comprises an installation base. The installation base is provided with two installation supports. The upper ends of the installation supports are provided with installation platforms. One installation platform is provided with an installation rod, and the other installation platform is provided with a supporting air cylinder. The stir-frying device comprises a stir-frying cylinder. The exteriors of the two ends of the stir-frying cylinder are sleeved with installation rings. Bearings are arranged between the installation rings and the stir-frying cylinders. One installation ring is hinged to the upper end of the installation rod, and the other installation ring is hinged to the output end of the supporting air cylinder. The exterior of the stir-frying cylinder is fixedly provided with a stir-frying gear. The installation base is provided with a stir-frying motor. An output shaft of the stir-frying motor is provided with a stir-frying motor gear. The screening function is achieved, the situation that tea is broken during stir-frying can be avoided, the tea forming quality is guaranteed, meanwhile, the teacan be automatically put into and taken out, and the labor cost is reduced.

Owner:宁强县千山茶业有限公司

Efficient energy-saving environment protective beige frying kitchen range

The invention provides a high-efficiency energy-saving environment-friendly fried rice color cooker. The cooker comprises an upper barrel body, a fried pot, a cooker body and a stirring device, wherein the cooker body comprises a cooker wall and a circular hearth; the fried pot is arranged in the upper barrel body and on the upper end of the circular hearth; the bottom surface of the fried pot and the upper end of the cooker body are in sealing fit; the upper barrel body is positioned on the upper end of the cooker body, the lower end of the upper barrel body and the upper end of the cooker body are in sealing fit; the stirring device is fix above the fried pot by a portal frame; and the inner wall of the circular hearth is provided with two burners respectively. The cooker of the invention has the advantages of improving the utilization ratio of heat energy in the fried color technological process and the production efficiency, lowering the labor intensity and improving the production environment.

Owner:JIANGSU HENGSHUN VINEGAR IND +1

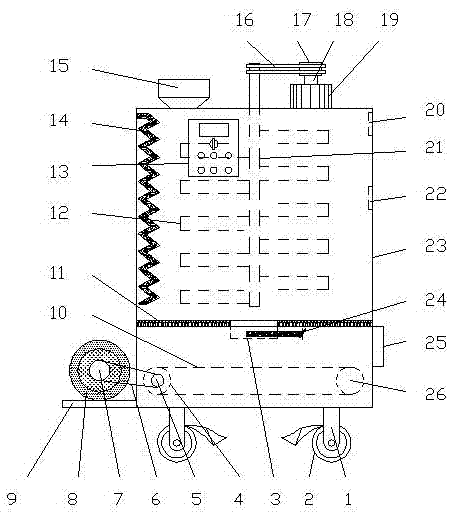

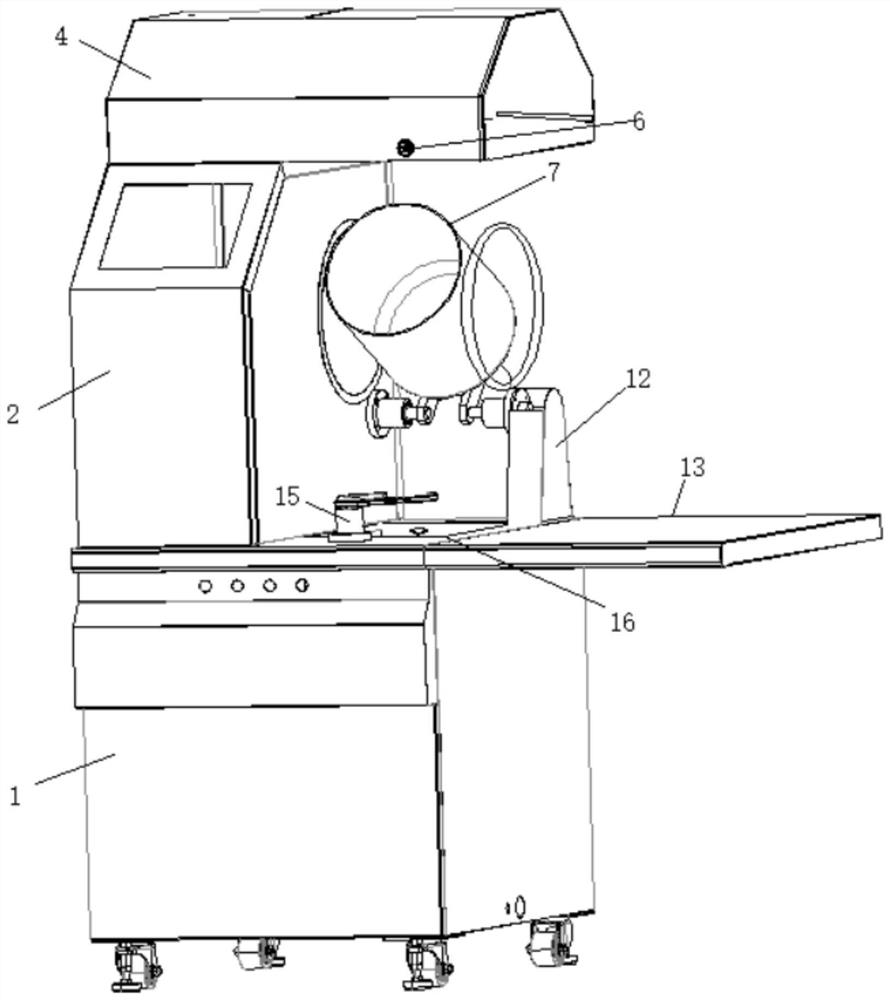

Tea processing machine

InactiveCN105432830AEasy to controlConvenient discharge workPre-extraction tea treatmentDrive wheelSolenoid valve

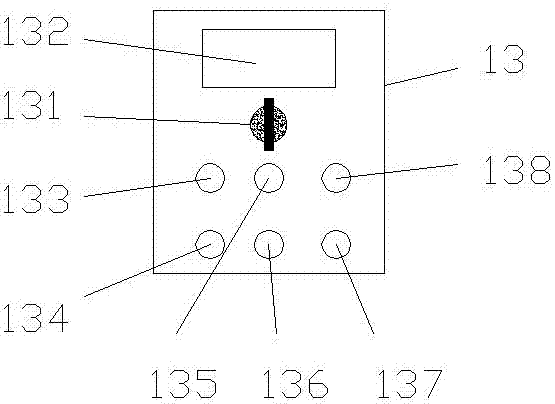

The invention discloses a tea processing machine comprising a shell and a heating wire, wherein a temperature sensor is arranged on the upper end at the right side of the inner cavity of the shell; the lower end of the outer side of the temperature sensor is provided with a humidity sensor; the upper end at the left side of the inner cavity of the shell is provided with the heating wire; the lower end of the inner cavity of the shell is provided with a baffle; the middle end of the inner cavity of the baffle is provided with a first discharging opening; the lower end of the inner cavity of the first discharging opening is provided with a solenoid valve; the right end of the bottom of the inner cavity of the shell is provided with a driven wheel which is in transmission connection with a driving wheel through a conveyor belt. The tea processing machine is provided with the temperature sensor, can display temperature in the shell through a display screen, is convenient for controlling temperature in the shell by people, can automatically switch off the heating wire and stop continuous heating when the temperature reaches the highest preset value, can automatically switch on the heating wire when the temperature reaches the lowest preset value, and thus the self-heating of the heating wire can be realized, the loss of the electric energy can be reduced and the stir-frying quality of the tea leaves can also be ensured.

Owner:HENGYANG ZHIYUAN AGRI TECH

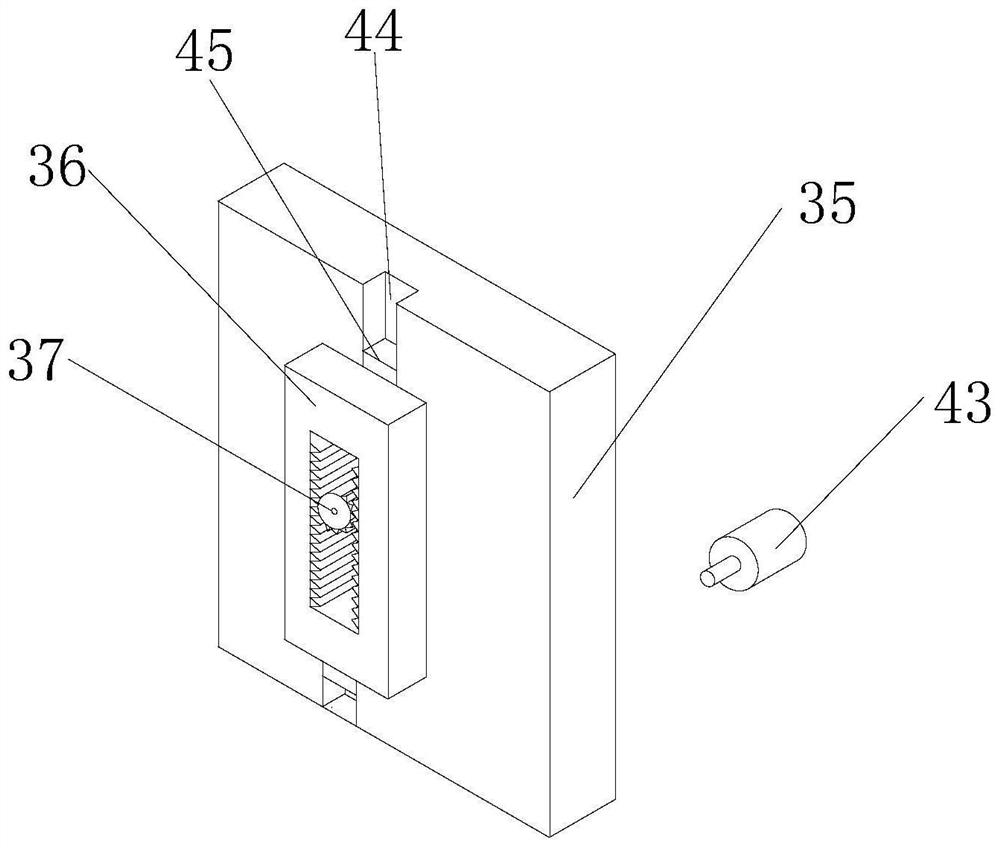

Tea leaf stir-frying machine

InactiveCN107751428AFried evenlyAvoid fryingPre-extraction tea treatmentAgricultural engineeringMotor shaft

The invention discloses a tea frying machine, which comprises a base, a frying barrel, a frying device, a frying rod and a motor. Support rods are respectively fixedly connected to both sides of the top center of the base, and the two sides of the frying barrel The side is movably connected to the support rod, the upper right end of the frying barrel is provided with a material inlet, and the left end is provided with a discharge port, the inside of the frying barrel is connected with an electric heating tube, and the frying device is set On the right side of the frying barrel. The present invention can solve the problem of extremely low efficiency and high labor intensity in the prior art of manual frying, and solves the problem that tea leaves are easily burnt and wasteful. The present invention is simple in structure and easy to use. Tube heating can prevent overheating, and through the turning of the frying rod, it can effectively prevent the scorching of tea leaves caused by long-term heating at the same place, and the frying device can make the roasted tea leaves more uniform, greatly Improve the frying quality of tea.

Owner:ANHUI SHITAI COUNTY XIHUANGSHAN TEA IND

Production method of fried puffed flavored fish skin

InactiveCN110810753AReduce generationReduce the impact of damageDomestic cooling apparatusLighting and heating apparatusCold airProcess engineering

The invention discloses a production method of fried puffed flavored fish skin. The production method comprises the following steps: S1, treating raw materials; S2, performing segmentation; S3, performing pickling; putting the cut fish skin into a pickling barrel, and pickling for 20-40 minutes; S4, frying for the first time; adjusting the oil temperature of the frying and cooling integrated equipment to 125-130 DEG C, performing low-temperature frying, and performing frying for 8 min; S5, performing cooling; turning on a cold air device for cooling to the normal temperature of 20-25 DEG C; S6, performing deep-frying puffing for the second time; adjusting the oil temperature of the frying and cooling integrated equipment to 170 DEG C, and carrying out secondary frying puffing by utilizingmoisture contained in the primary frying; S7, filtering oil; S8, performing cooling; S9, performing seasoning; S10, performing drying; and S11, performing modified atmosphere packaging. The fresh fishskin or frozen fish skin is adopted as a raw material, the flavor fish skin product is prepared through the procedures of cleaning, cutting, pickling and the like, a secondary frying method and a fusion puffing technology are employed, and the obtained flavor fish skin has special taste and high quality and is long in shelf life and easy to store.

Owner:安徽灵猫食品有限公司

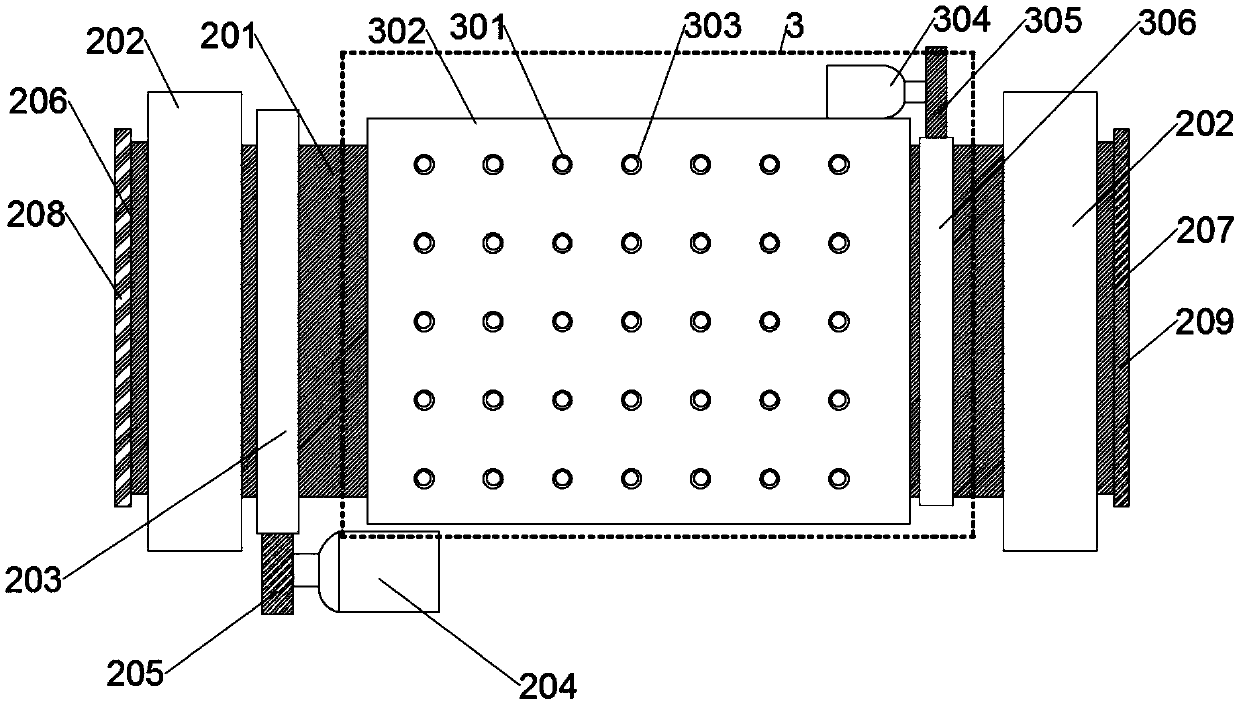

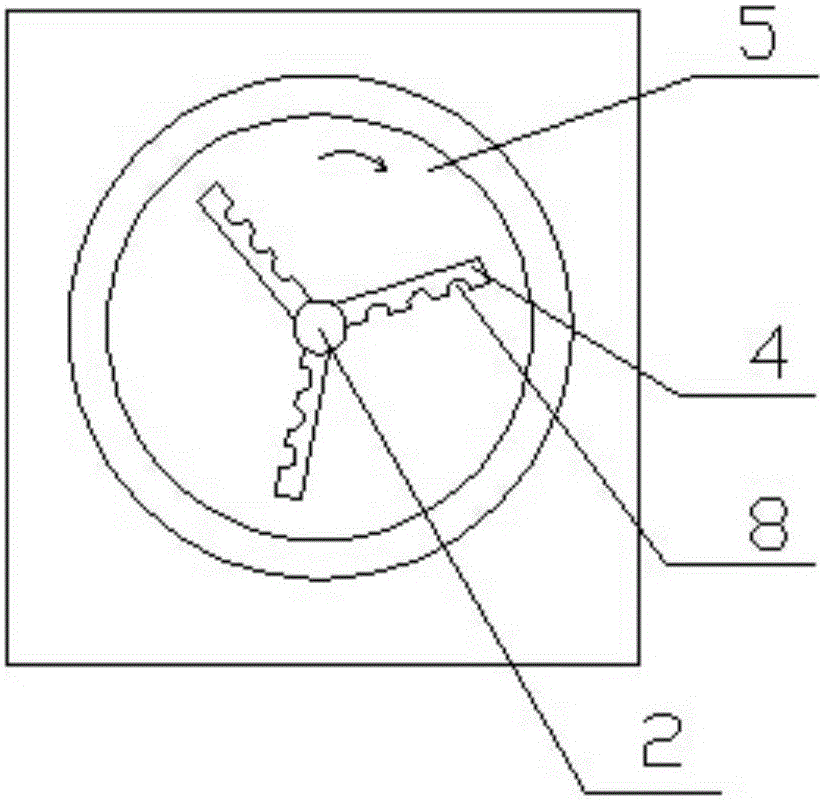

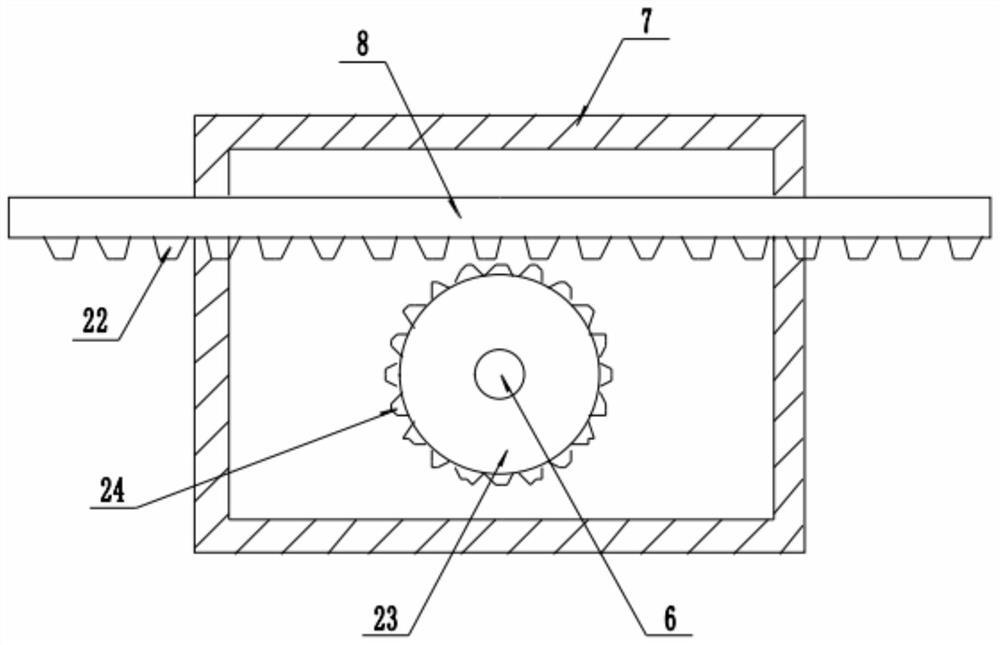

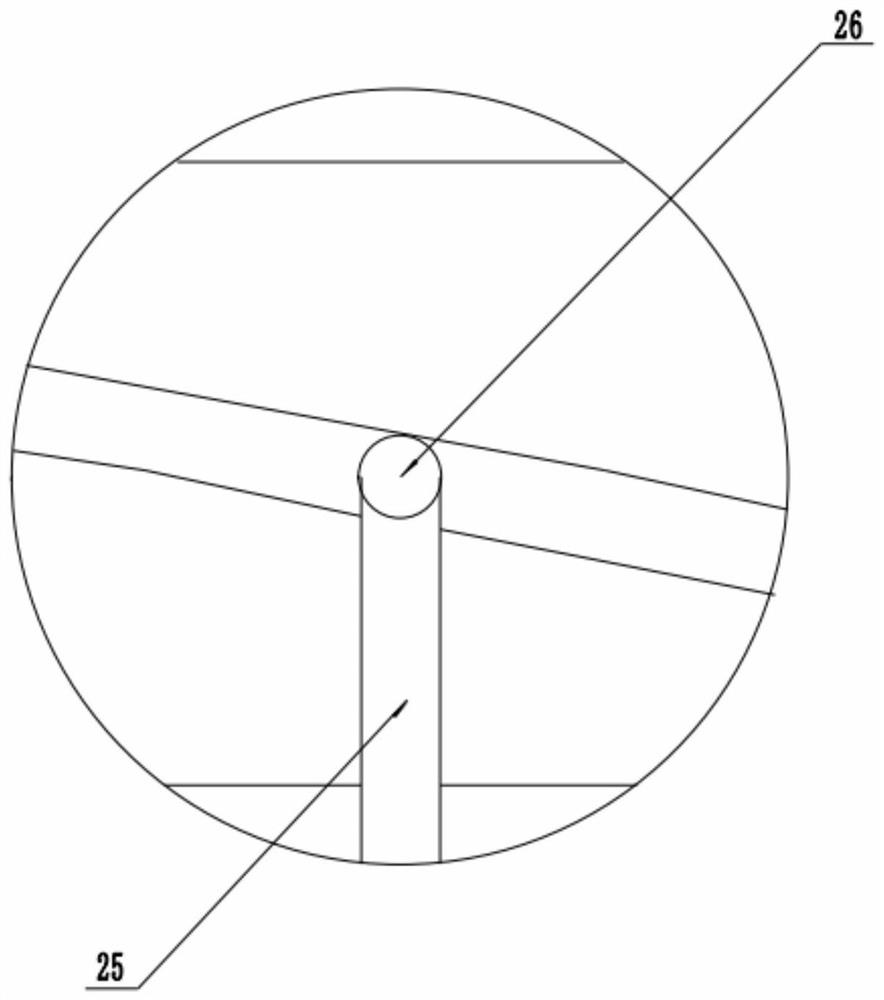

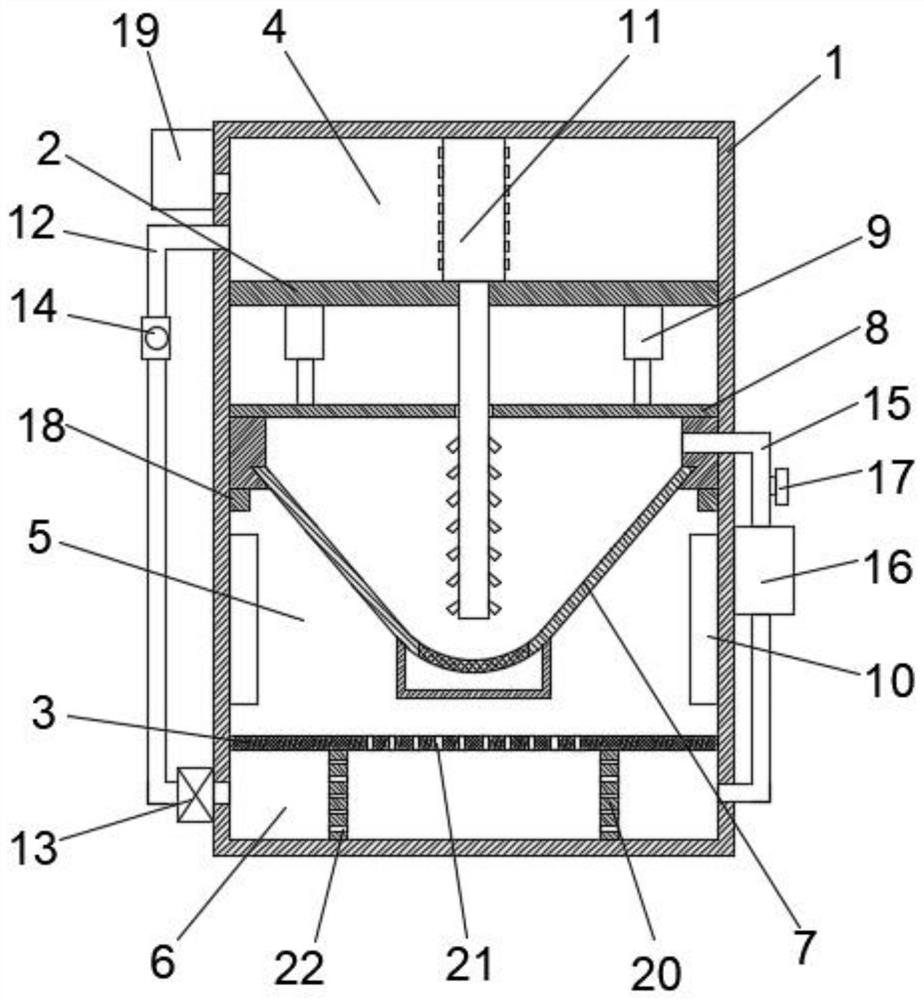

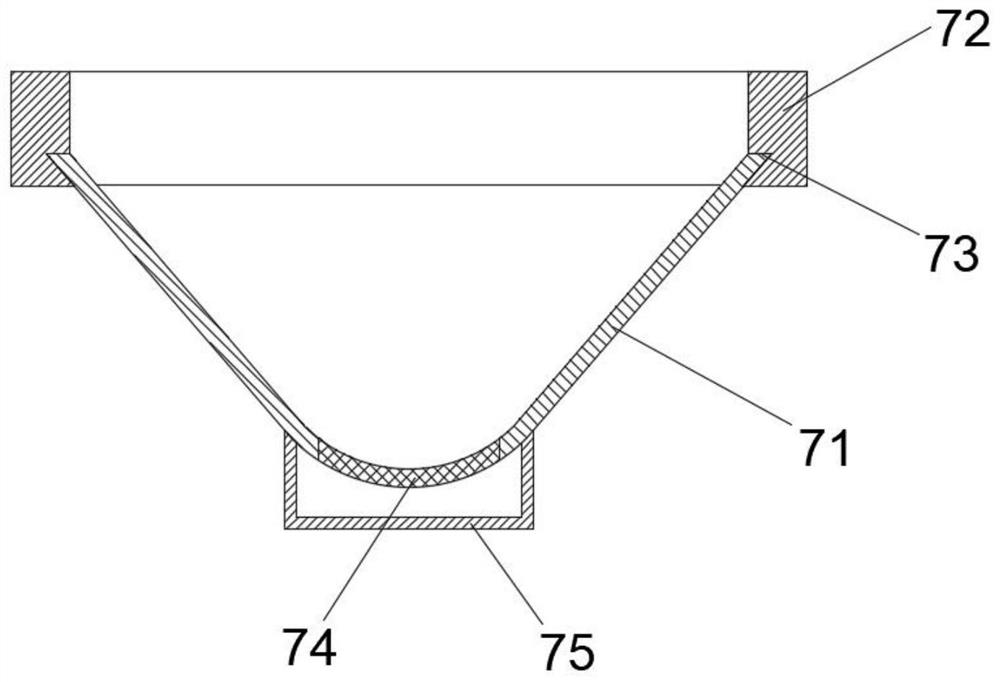

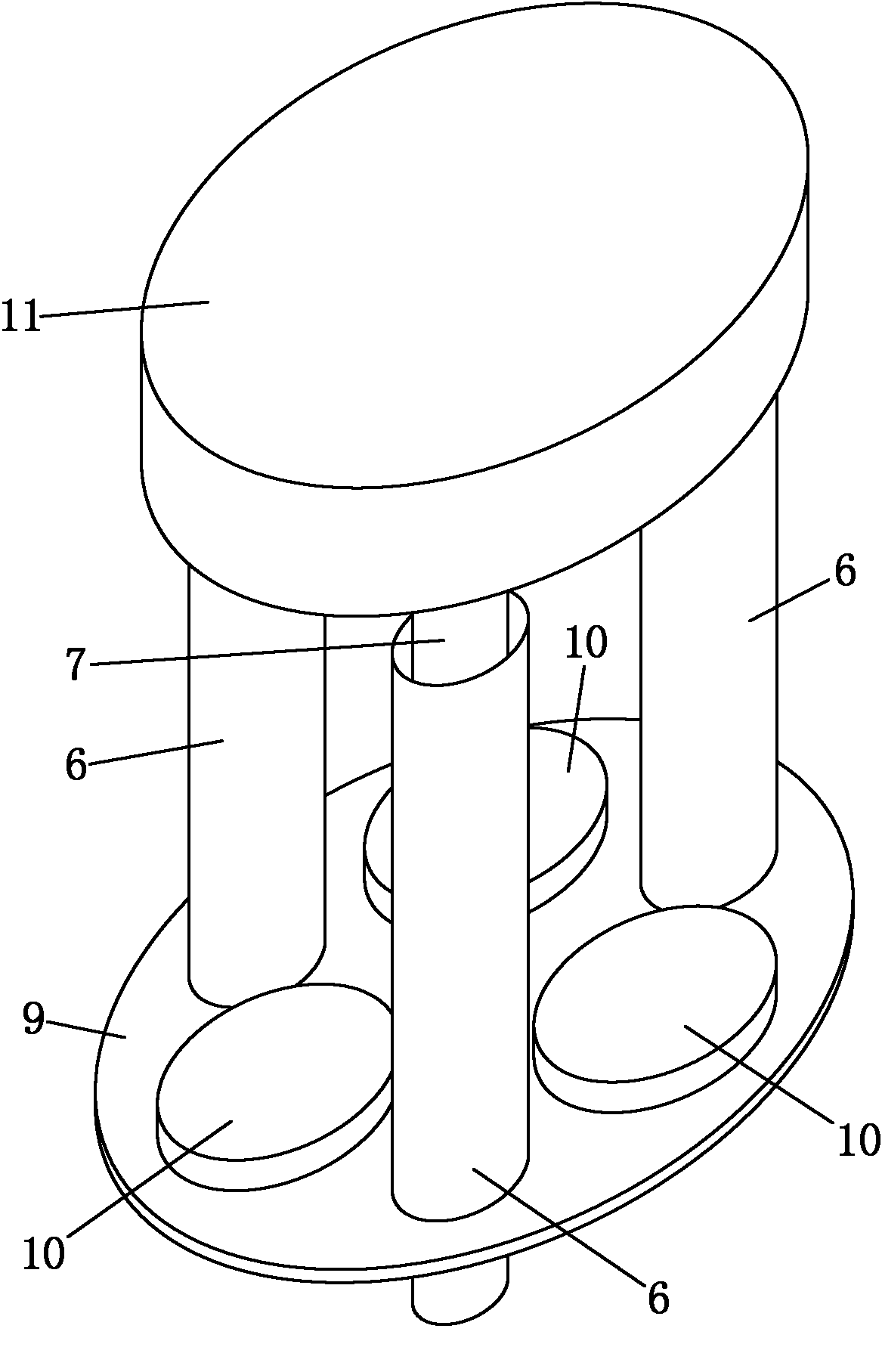

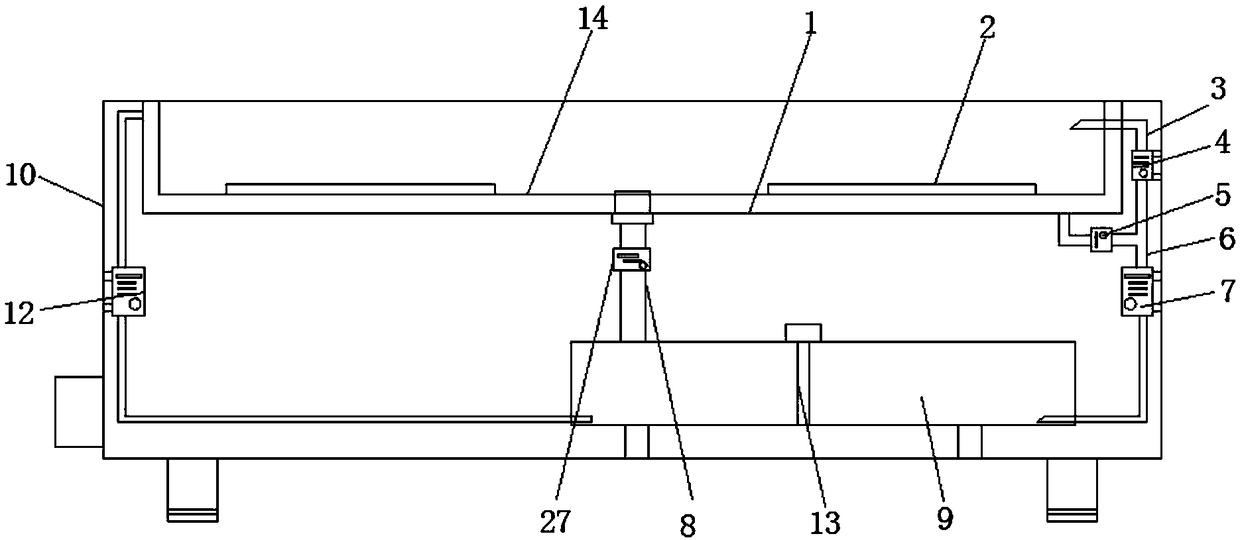

Roasting drum device of herbal medicine roaster

InactiveCN104997636AObserve the frying situation at any timeGood frying qualityPharmaceutical product form changeEngineeringMechanical engineering

The invention discloses a roasting drum device of a herbal medicine roaster. The roasting drum device comprises a drum body, a door cover and a stir-roast device, wherein the door cover is connected to one end of the drum body; the stir-roast device is detachably connected to the interior of the drum body through a rotating shaft; a discharge opening is formed in the bottom of the drum body, and a flip-open cover is also arranged at the bottom of the drum body; the stir-roast device comprises a loop bar and no less than three stirring blades; a plurality of grooves with semi-circular cross sections are formed in the surface of each stirring blade; the grooves faces toward the rotation directions of the stirring blades; the rotating shaft is inserted into the loop bar. The roasting drum device has the advantages and positive results that the characteristics of being simple in structure, convenient to use and good in herb roasting equality, allowing the herb roasting situations to be observed at any time and the like are achieved, the production efficiency is improved, the roasting drum device is suitable for roasting processing of various herbs with different specifications and properties, the roasted herbs are fresh and uniform in color, and the stirring blades can be detached and replaced for roasting of different herbs.

Owner:TIANJIN BOAI PHARMA

Tea drying device

InactiveCN112033136AIncrease profitEvenly heatedGas current separationPre-extraction tea treatmentReciprocating motionElectric machinery

The invention relates to the technical field of tea drying and discloses a tea drying device which comprises a drying device body, the body comprises a supporting plate, a first shell is fixedly connected to the supporting plate, a longitudinal stirring device is arranged in the first shell, the longitudinal stirring device comprises a second transverse plate, a transverse stirring device is arranged on the second transverse plate, and the transverse stirring device comprises a first transverse plate. A secondary drying device is arranged on the upper surface of the first transverse plate, a residue collecting device is further arranged on the upper surface of the first transverse plate, a primary water-removing device is further arranged on the upper surface of the supporting plate, and asixth gear is driven to rotate through rotation of a second motor. When gear teeth of the sixth gear mesh with the gear opening of the right side wall in a second gear belt, the rotation of the sixthgear drives a second sliding block on the second gear belt to slide in a first sliding groove, the second gear belt drives a second box body to move upwards, a second motor rotates continuously, thesecond box body of the tea drying device is driven by the longitudinal stirring device to reciprocate up and down, tea in the second box body are turned over, heating is more uniform, and the tea frying effect is better.

Owner:李庆贵

Drum type tea leaf stir-frying machine

InactiveCN107581293AFried evenlyEasy to fryPre-extraction tea treatmentAgricultural engineeringEngineering

The invention discloses a drum type tea leaf stir-frying machine, which comprises a base, a heating barrel, a stir-frying barrel, a stir-frying device and a motor, wherein support rods are fixedly connected to two sides of a central position of the top part of the base respectively; two sides of the heating barrel are movably connected with the support rods; a feed inlet is formed in the right upper end of the heating barrel; a discharge hole is formed in the left end of the heating barrel; an electrical heating pipe is connected into the heating barrel; the stir-frying device is arranged at the right side of the heating barrel. The drum type tea leaf stir-frying machine provided by the invention can solve the problems that according to manual stir-frying in the prior art, the efficiency is low and the labor intensity is high, solves the problem that tea leaves are easily burnt so as to cause waste, and is simple in structure and convenient to use; the electrical heating pipe is used for heating, so that overheating can be prevented; the stir-frying barrel is used for stirring, so that the phenomenon that the tea leaves are burnt due to being heat for a long time at the same placeis effectively prevented; the stir-fried tea leaves can be more uniform through the stir-frying device, so that the stir-frying quality of the tea leaves is greatly improved.

Owner:ANHUI SHITAI COUNTY XIHUANGSHAN TEA IND

Stir-frying method of traditional Chinese medicine decoction pieces

InactiveCN107890426AUniform colorGood lookingPharmaceutical product form changeTreatment effectTraditional medicine

The invention provides a stir-frying method of traditional Chinese medicine decoction pieces. The stir-frying method comprises the following steps: pretreating the traditional Chinese medicine decoction pieces, preparing auxiliary materials for stir-frying, carrying out stir-frying, etc. Through the reasonable treatment for the raw materials and the selection and optimization for the auxiliary materials during the stir-frying process, the traditional Chinese medicine decoction pieces obtained through stir-frying are uniform in color, high in appearance and character uniformity, and rich in medicinal aroma, the keeping quality of the medicinal property is good, the quality of the decoction pieces is stable, and the treatment effects are strong.

Owner:和治佳凯药业股份有限公司

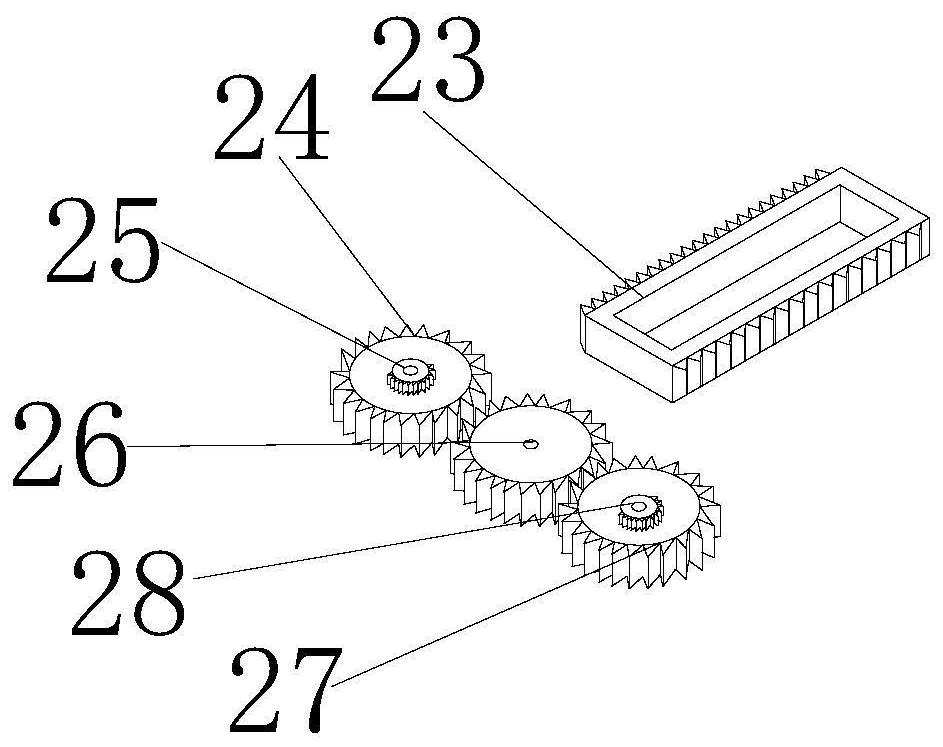

Full-automatic deep-frying device for chicken cutlets

InactiveCN112806401AFried evenly and effectivelyImprove the frying effectOil/fat bakingFood processingFood products

The invention relates to the technical field of food processing, and discloses a full-automatic deep-frying device for chicken cutlets. The full-automatic deep-frying device comprises a fixed bottom plate, wherein a hot oil tank is mounted in the middle of the upper end of the fixed bottom plate; telescopic cylinders are mounted on two sides of the upper end of the fixed bottom plate; telescopic columns are mounted at the upper ends of the telescopic cylinders; a rotating shaft is mounted between the upper ends of the telescopic columns; a rotating cylinder is mounted in the middle of the rotating shaft; a rotating groove is formed in the rotating cylinder; a sliding ball is arranged in the rotating groove in a sliding manner; a sliding column is mounted at the lower end of the sliding ball; the bottom of the sliding column penetrates through a limiting plate arranged between the telescopic columns and is connected with a moving box; a rotating wheel is rotatably arranged in the moving box; a plurality of gear rings are arranged on the outer side of the rotating wheel; the rear ends of the gear rings are meshed with racks; and the racks are fixed at the front end of a fixed plate. According to the full-automatic deep-frying device disclosed by the invention, a deep-frying frame can rotate while moving left and right, so that uniform and effective deep-frying of the chicken cutlets in the deep-frying frame is guaranteed; and an oil spraying cavity can continuously spray hot oil towards the direction of the deep-frying frame, so that the deep-frying effect of the surfaces of the chicken cutlets is guaranteed, and the deep-frying quality is further improved.

Owner:SHANDONG JIASHIBO FOOD

Inner drum type tea leaf frying machine

InactiveCN107568361AFried evenlyEasy to fryPre-extraction tea treatmentAgricultural engineeringElectric heating

The invention discloses an inner drum type tea leaf frying machine. The inner drum type tea leaf frying machine comprises a base, a heating bucket, a frying bucket, a frying device and a motor, wherein support rods are fixedly connected to two sides of the center of the top of the base respectively; two sides of the heating bucket are movably connected to the support rods, a feeding hole is formedin the right upper end of the heating bucket, a discharging hole is formed in the left end of the heating bucket, and an electric heating pipe is connected to the inside of the heating bucket; and the frying device is arranged on the right side of the heating bucket. According to the inner drum type tea leaf frying machine, the problems that extremely low efficiency and high labor strength of a manual frying manner in the prior art are solved, and the problems that tea leaves are easily fried to be brown and are wasted are solved; the inner drum type tea leaf frying machine is simple in structure and convenient to use; by heating through the electric heating pipe, the overheating can be prevented; by virtue of the turning of the frying bucket, the situation that the tea leaves are coked after being fried at the same place for a long time is effectively prevented; and by utilizing the frying device, the fried tea leaves are relatively uniform, and the frying quality of the tea leaves is greatly improved.

Owner:ANHUI SHITAI COUNTY XIHUANGSHAN TEA IND

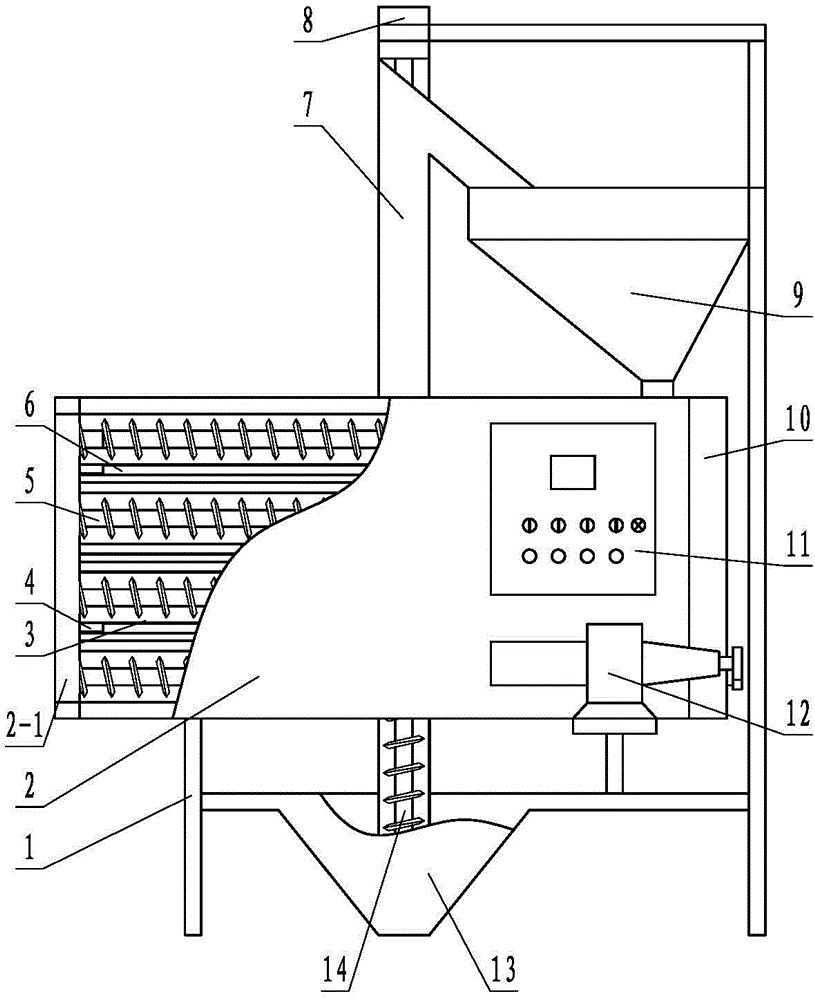

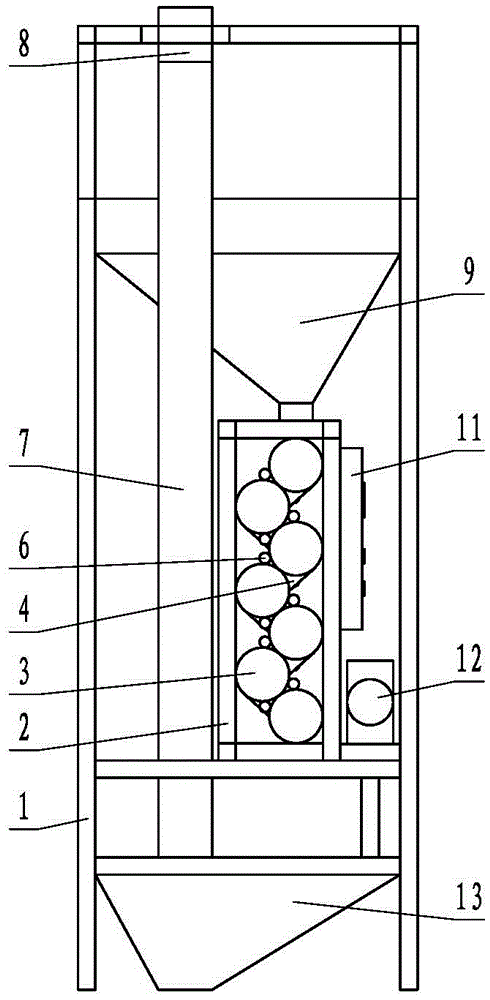

Peanut stir-frying machine

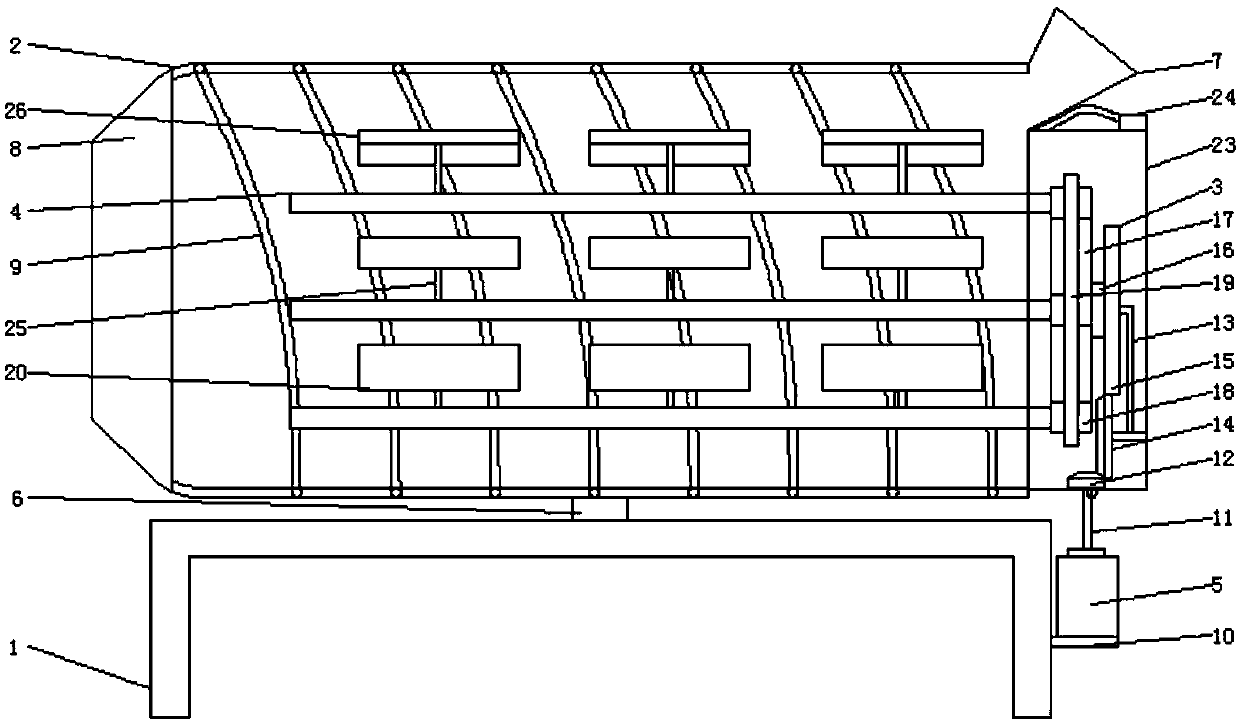

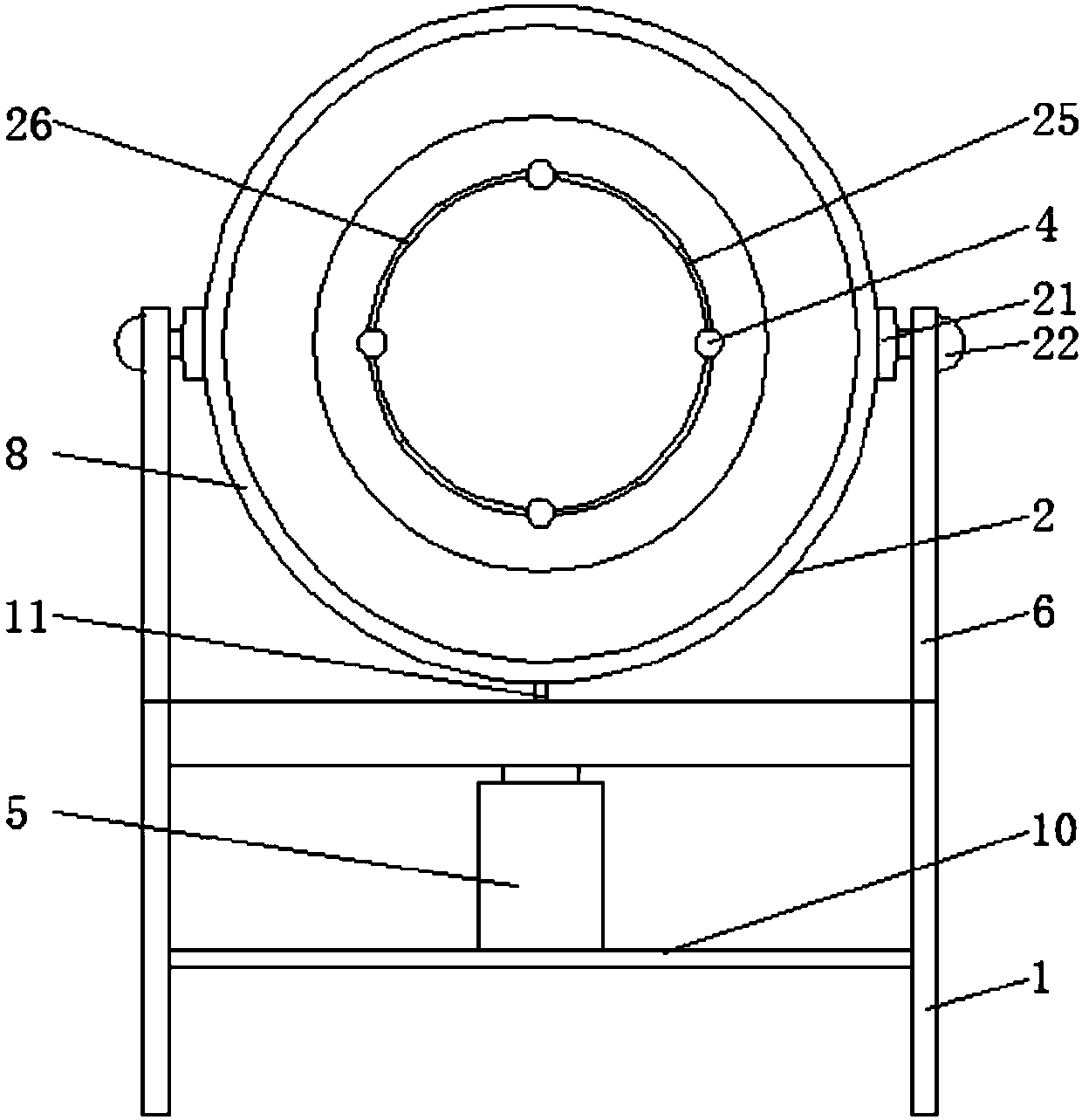

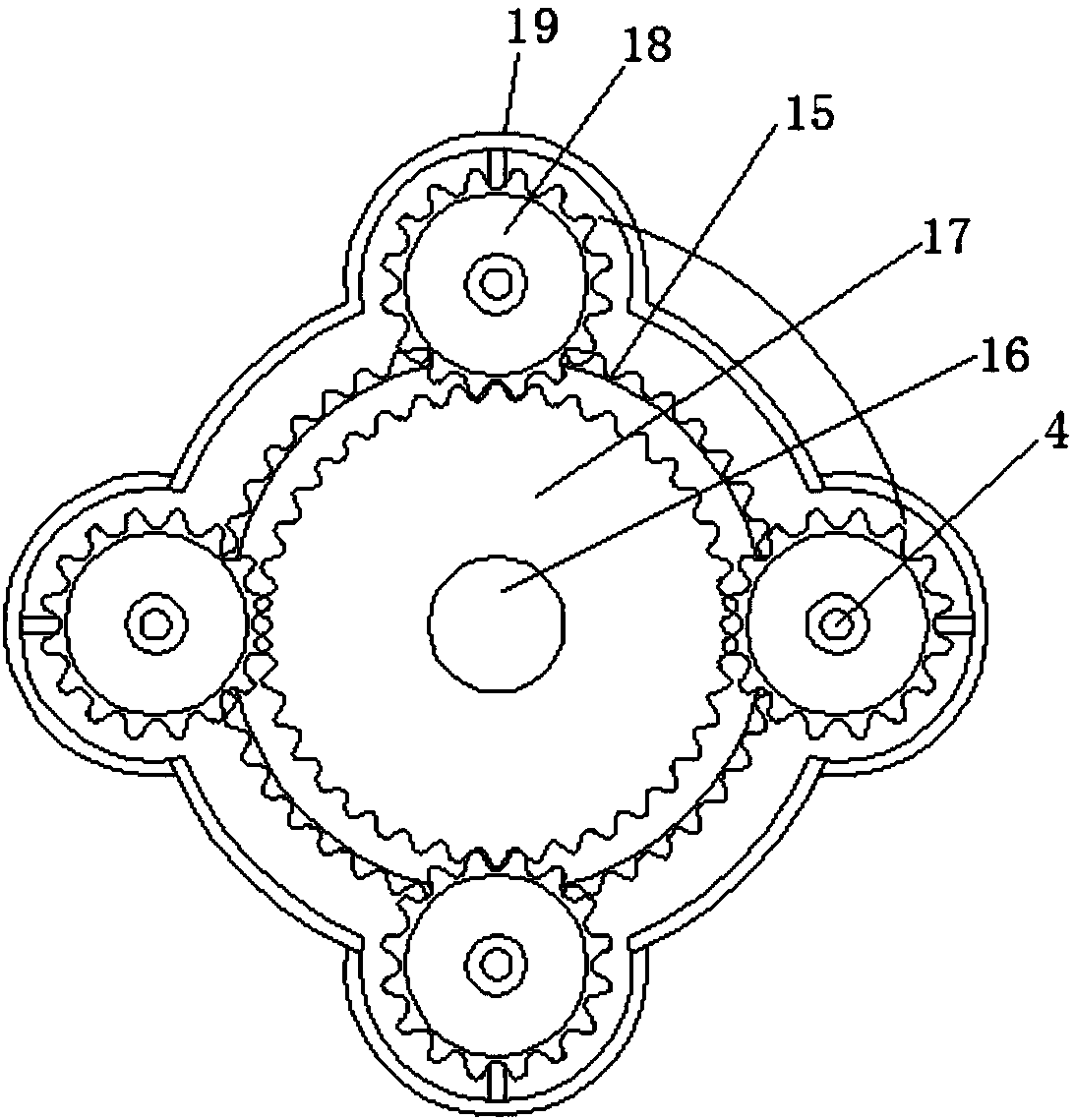

InactiveCN106108070AIncrease frequencyExtend the cooking timeFatty-oils/fats productionFood treatmentEngineeringMaterial storage

The invention discloses a peanut stir-frying machine, which relates to the technical field of food processing equipment. It includes an incubator installed on a frame, and a plurality of stir-fry barrels arranged up and down are fixed in the heat preservation box. Connected, heating tubes are installed on both sides of the abutment of adjacent frying barrels, and the heating tubes are arranged along the length direction of the frying barrels; the inlet and outlet of adjacent frying barrels are turned horizontally, located The discharge port of one layer is connected with the feed port of the same end of the next layer through the feed pipe; each frying barrel is provided with a screw feeding rod, and the advancing direction of the adjacent screw feeding rods is opposite; There is a material storage box, which communicates with the feed hopper through a lifting channel, and a lifter is arranged in the lifting channel; the motor, the heating pipe and the lifter are respectively electrically connected with the control box. The invention solves the problems of poor frying quality and low frying efficiency of the existing peanut frying machine.

Owner:吴荣

Potato frying equipment for puffed food production

PendingCN113068725AGuarantee the consistency of frying effectUniform oil temperatureBaking ovenOil/fat bakingElectric machineryEngineering

The invention discloses a potato frying equipment for puffed food production, which comprises a frying box and a material box, heating strips are arranged in the frying box, the bottom of the frying box is communicated with an oil discharge pipe, a valve is arranged on the oil discharge pipe, the right end of the frying box is fixedly provided with a top plate, a slide rail and a machine plate in sequence from top to bottom, a first motor is fixedly installed at the top of the machine plate, the output end of the first motor is fixedly connected with a first rotating rod, the outer surface of the first rotating rod is fixedly sleeved with a driving bevel gear, and the end, away from the first motor, of the first rotating rod penetrates through the frying box and is rotationally connected with the interior of the left side of the frying box; the outer surfaces of the left side and the right side, located in the frying box, of the first rotating rod are fixedly sleeved with stirring rods, a bearing seat is fixedly installed on the lower surface of the top plate, a lead screw is rotationally connected into the bearing seat, a driven bevel gear is fixedly installed at the bottom of the lead screw, and the driven bevel gear and the driving bevel gear are meshed with each other. The potato frying equipment disclosed by the invention is compact in structure and can effectively improve the potato frying quality.

Owner:安徽省小岗盼盼食品有限公司

Tea leaf stir-frying machine

PendingCN111771993AAvoid Stir-FryingImprove frying qualityPre-extraction tea treatmentEngineeringGas heating

The invention discloses a tea leaf stir-frying machine. The tea leaf stir-frying machine comprises a stir-frying cylinder, wherein the inside of the stir-frying cylinder is divided into an air-blowingchamber, a stir-frying chamber and a gas heating chamber from top to bottom in sequence by a sealing plate and a heat insulation plate, a wok assembly is arranged in the stir-frying chamber, a sliding cover plate is arranged above the wok assembly, the sliding cover plate is connected with the lower end of the sealing plate through pneumatic rods, the inner wall of the stir-frying chamber is fixedly connected with heating plates, the air-blowing chamber and the stir-frying chamber communicate with each other through an air inlet assembly, the gas heating chamber and the air-blowing chamber communicate with each other through an air inlet pipe, the air inlet pipe is equipped with an exhaust fan and a one-way valve, the side wall of the upper end of the stir-frying chamber communicates withthe gas heating chamber by an air outlet pipe through a gas treatment box, and a manual valve is installed on the air outlet pipe. According to the tea leaf stir-frying machine, the heating plates are used to heat the stir-frying assembly in the stir-frying chamber, and the air inlet pipe and the air outlet pipe are used to inflate tea leaves in the stir-frying assembly, so that the tea leaves are suspended and stirred, the stir-frying damage of the tea leaves is avoided, the heating is uniform, the tea leaf frying quality is improved, and the green odor during the tea leaf frying process canbe taken away by using gas circulation.

Owner:安徽省霍山县永宏茶业有限公司

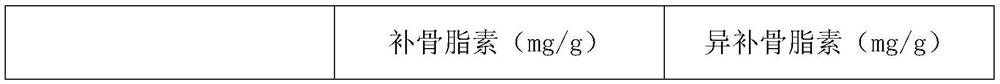

Processing method for salt roasting of psoralea corylifolia

InactiveCN112315994AImprove the quality of detoxificationImprove frying qualityPlant ingredientsProcess engineeringFood science

The invention discloses a processing method for salt roasting of psoralea corylifolia, and belongs to the technical field of processing of traditional Chinese medicinal materials. The processing method comprises the following steps: (1) preparing an iodine-free edible salt salt-water mixture, and stirring and mixing salt with water according to the proportion of 1: 5; (2) heating the salt-water mixture; (3) moistening the psoralea corylifolia: uniformly stirring the psoralea corylifolia with the salt-water mixture according to the weight ratio of 10: 5, and performing moistening; (4) stir-frying the moistened psoralea corylifolia in a medicine stir-frying pot until the psoralea corylifolia slightly bulges and the surface of the psoralea corylifolia is black or black brown, and taking out astir-fried product; and (5) cooling the stir-fried product, and screening out medicine scraps and powder to obtain the salt-roasted psoralea corylifolia. The processing method is high in practicability, the salt-water proportion, the moistening and stir-frying time and the stir-frying temperature are defined by the processing method, the time and the temperature are controlled according to requirements, and therefore, the problems that the processed psoralea corylifolia is extremely low in medicinal value and poor in medicine effect functionality in existing salt-roasted psoralea corylifoliaare effectively solved.

Owner:遵义廖元和堂药业有限公司

Walnut stir-frying apparatus

InactiveCN108523168AImprove air flowImprove quality and efficiencyFood treatmentWalnut NutDrive shaft

The invention provides a walnut stir-frying apparatus. The walnut stir-frying apparatus comprises a stir-frying barrel, a heating chamber, electric heating wires, a motor, a transmission shaft, a material allocating plate, a blower, an auxiliary material canister and a ventilating fan. The walnut stir-frying apparatus is characterized in that the stir-frying barrel is arranged on a support; the heating chamber is arranged at a bottom of the stir-frying barrel; the electric heating wires are arranged between heating blocks; the motor is arranged at one end of the stir-frying barrel; one end ofthe transmission shaft is arranged in a shaft sleeve; the material allocating plate is arranged on the transmission shaft; the blower is arranged on the stir-frying barrel; the auxiliary material canister is arranged on an auxiliary material tube; and the ventilating fan is arranged in a ventilating tube. According to the invention, the material allocating plate and an air outlet are arranged on arotating shaft of the motor so that chestnuts in the stir-frying barrel can be continuously stirred by the material allocating plate during stir-frying process, and thus, stir-frying quality and stir-fry efficiency of chestnuts are improved; moreover, dosage accuracy of auxiliary materials can be improved by adopting a scale so as to reduce waste of auxiliary materials and improve quality of stir-fried chestnuts.

Owner:芜湖市三山区绿色食品产业协会

Processing device for frying tea oil seeds

The invention relates to the technical field of tea oil, and discloses a processing device for frying tea oil seeds. The processing device for frying tea oil seeds comprises a support, wherein a frying table is fixedly installed on the upper end of the support, the upper end of the frying table is slidably connected with a drawer, and an accommodating pan is fixedly installed on the top of the frying table; the lower end of the accommodating pan is fixedly connected with a first sliding tube, the left part and right part of the accommodating pan are fixedly connected with sliding cylinders, and the lower end of the accommodating pan is slidably connected with piston rods; and the piston rods extend into the sliding cylinders and the inner cavity of the first sliding tube, and brush bars are arranged at the front end and rear end of each piston rod. According to the processing device for frying tea oil seeds, first gears are driven to rotate by a T-shaped rotating plate, then closed frames are driven by cranks, spring rods are driven to move by piston racks, and stirring claws are driven to rotate; a second sliding tube is pressed by cooperation of the piston racks, the first sliding tube is pressed to move, and impurities are brushed off by the brush bars, so that the frying quality of tea oil seeds is improved, and the removal rate of the impurities is accelerated.

Owner:徐睿琦

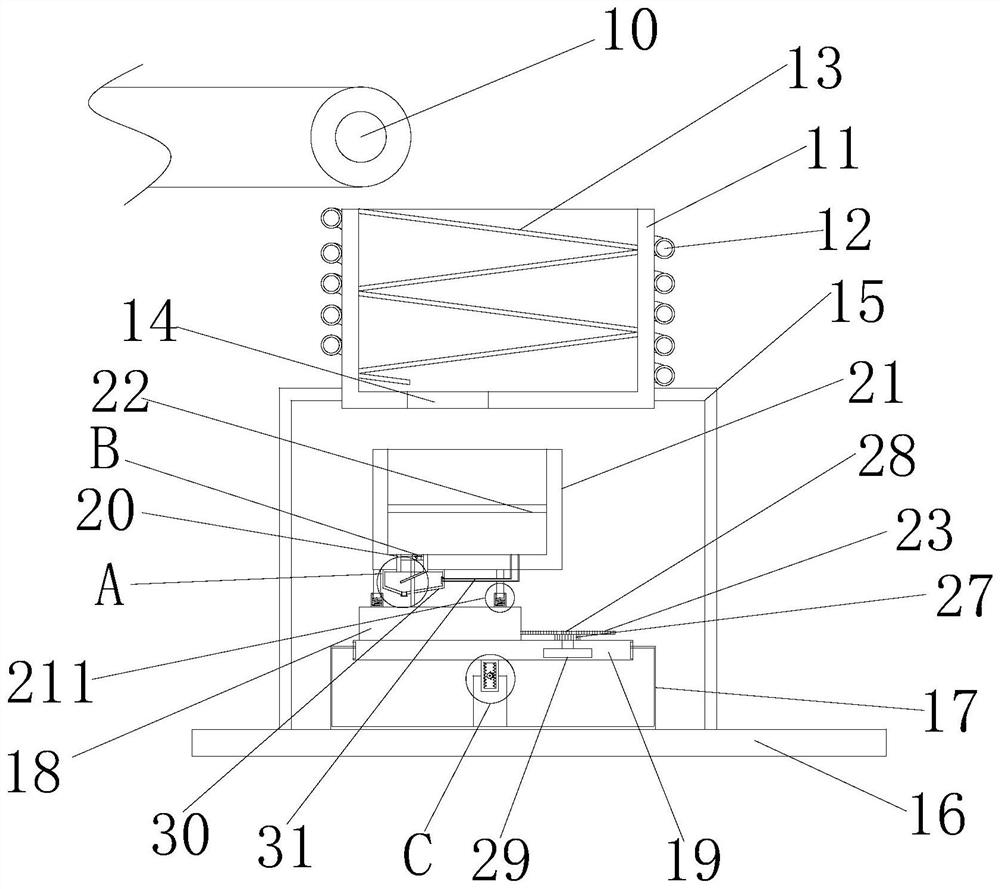

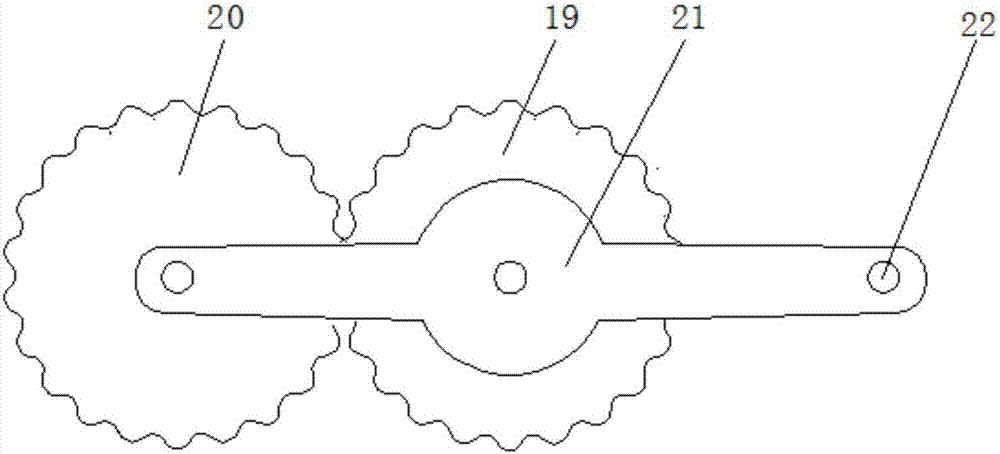

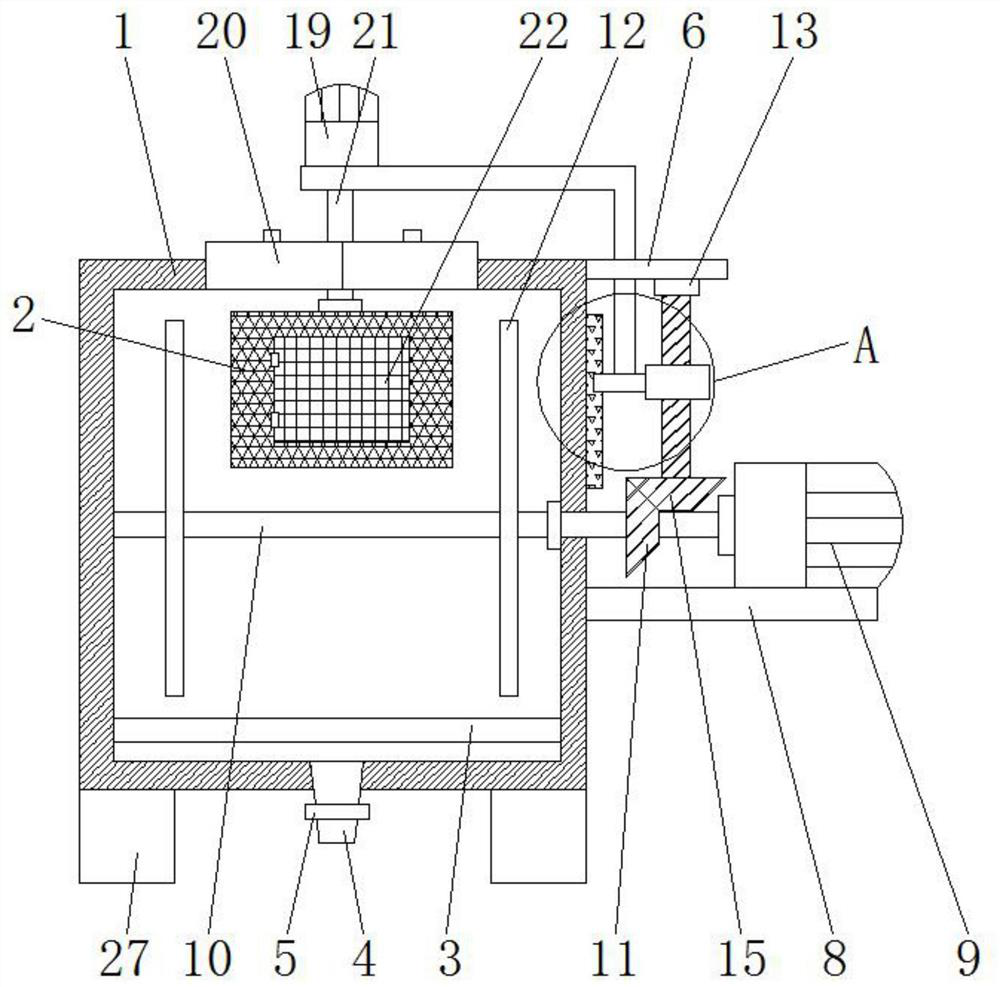

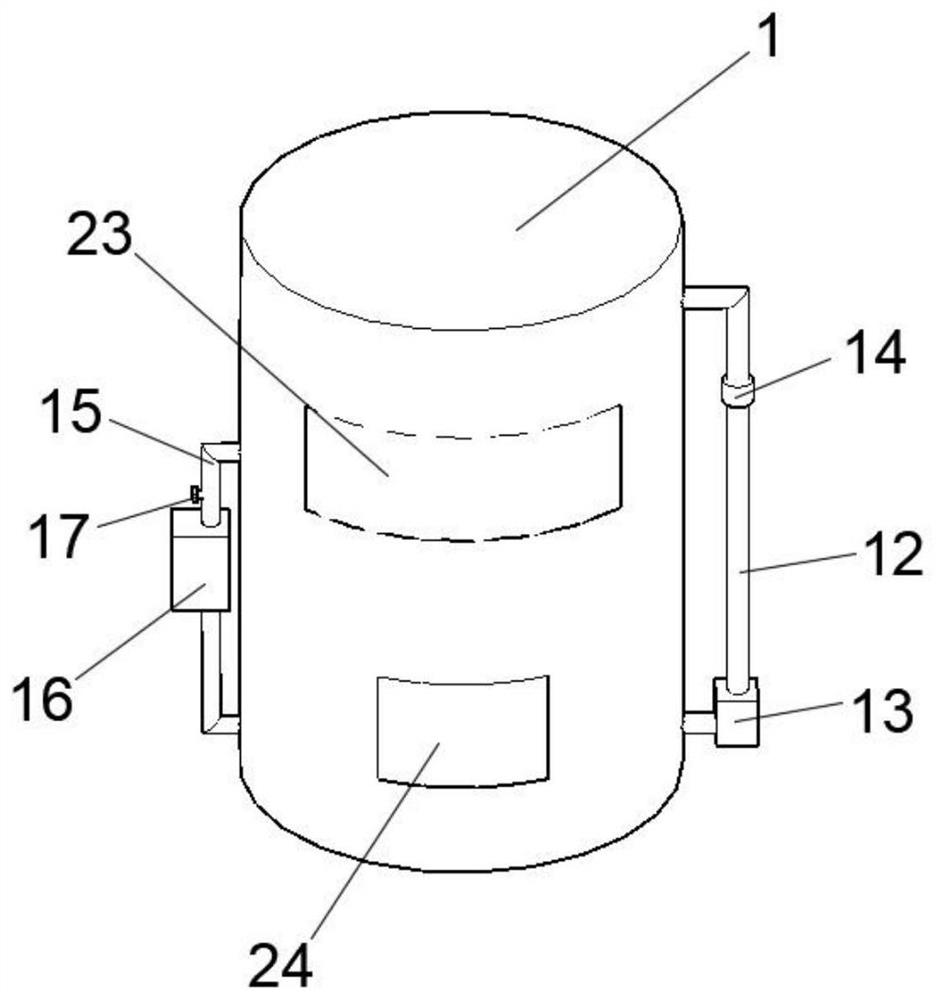

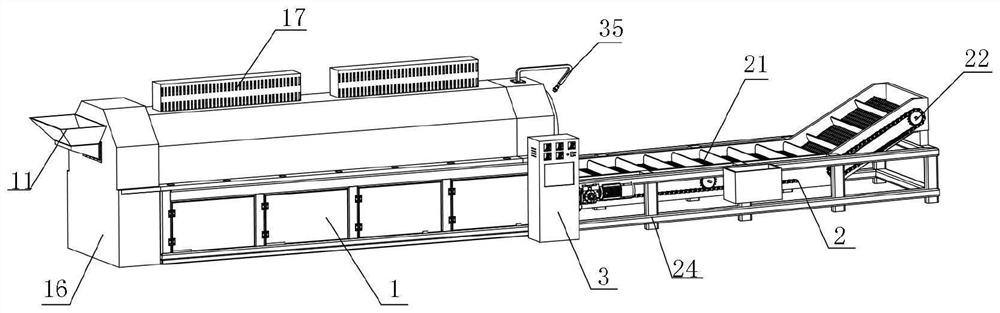

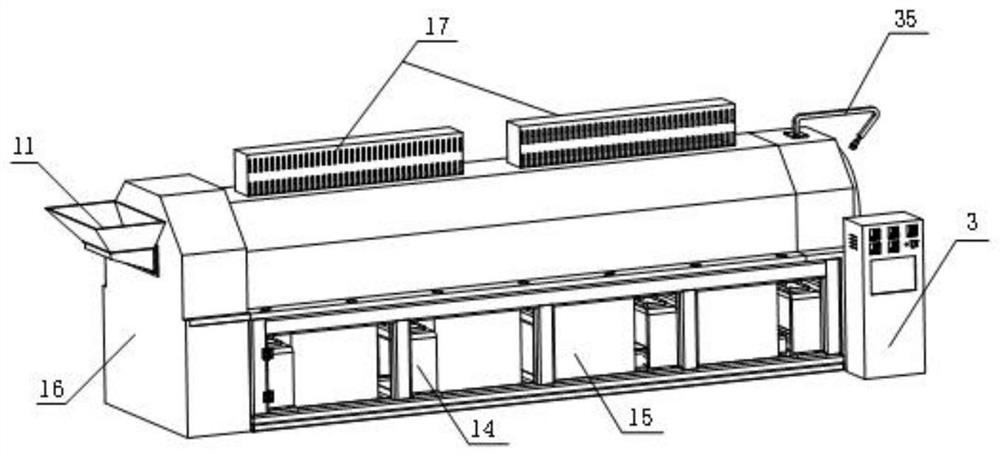

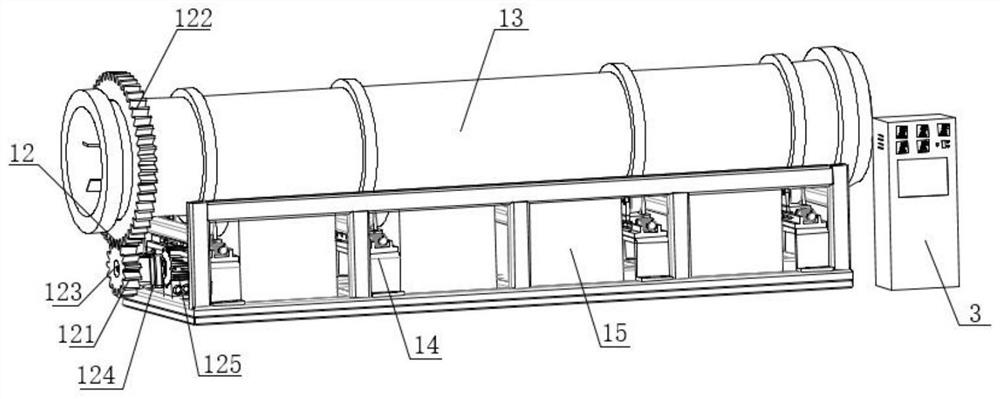

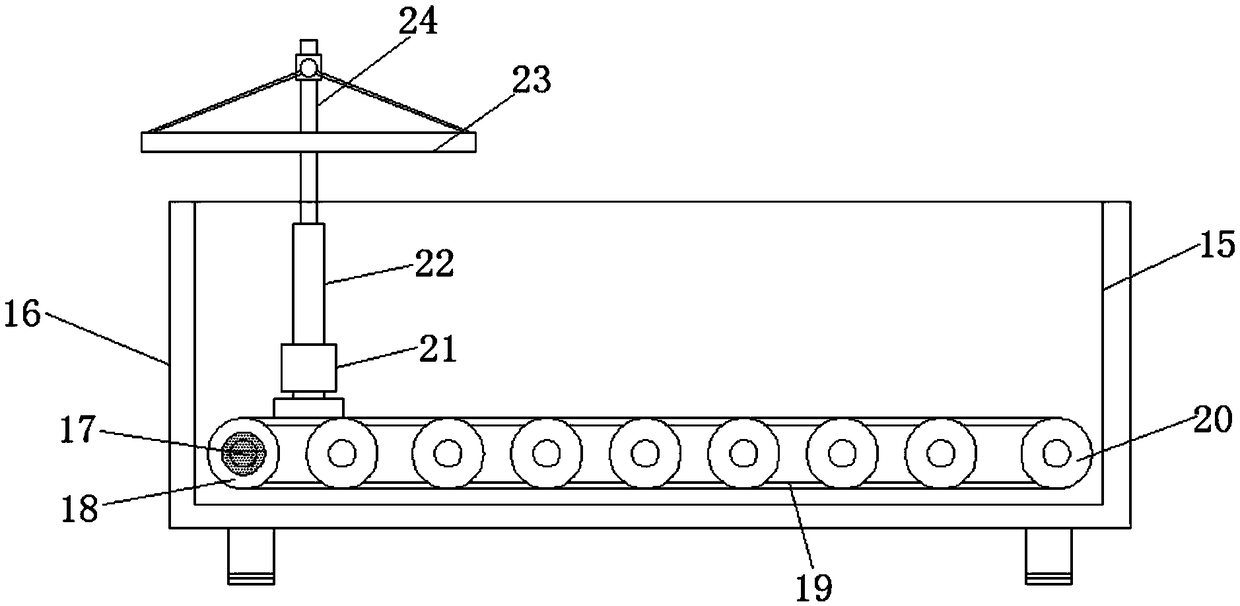

Full-automatic soaking and stir-frying device for Chinese torreya and stir-frying method thereof

PendingCN114527697AImprove frying qualityIncreased electromagnetic thermal efficiencyProgramme controlComputer controlTorreyaElectromagnetic heating

The invention provides a full-automatic soaking and stir-frying device for Chinese torreya and a stir-frying method thereof, the stir-frying device comprises a stir-frying assembly, a soaking assembly and a control assembly, the output end of the stir-frying assembly is connected with the input end of the soaking assembly, and the control assembly is located between the stir-frying assembly and the soaking assembly. The output end of the feeding hopper is connected with the input end of the roller, a transmission gear of the transmission mechanism and a lantern ring of the adjustable supporting mechanism are connected with the installation end of the roller respectively, the rack and the heat dissipation box are located at the lower end and the upper end of the roller respectively, the electromagnetic heater is fixedly connected with the lower end of the rack, and the outer cover is fixedly connected with the first installation end of the rack. The lower end of the soaking tank in the shell assembly is fixedly connected with the first mounting end of the shell, the driving mechanisms are symmetrically located on the two sides of the soaking tank in the shell assembly, and the water level sensor is located on the inner wall of the soaking tank in the shell assembly. The problems that processing is dispersed and quality is uneven during torreya grandis stir-frying at present are effectively solved, and complex manual technical labor is converted into intelligent soaking and stir-frying flow production.

Owner:慧诚自动化技术(宁波)有限公司

Fish bone type fish frying machine capable of producing fried fish in batches for canned fish processing and using method

InactiveCN111328842AImprove frying qualityEasy to removeOil/fat bakingFish processingProcess engineering

The invention discloses a fish bone type fish frying machine capable of producing fried fish in batches for canned fish processing and a using method, and relates to the field of canned fish production. The fish bone type fish frying machine capable of producing fried fish in batches for canned fish processing comprises a pot body, wherein a supporting ring is fixedly connected to the bottom of the pot body, a first supporting plate is fixedly connected to the inner wall of the supporting ring, a heater is fixedly connected to the upper surface of the first supporting plate, and the bottom ofthe pot body and the inner wall of the first supporting plate fixedly communicate with oil outlet pipes. According to the fish bone type fish frying machine capable of producing fried fish in batchesfor canned fish processing, fish is strung on a fish stringing needle, so that the surface of the fish can be fully combined with hot oil, the frying quality of the fish is improved, and the problemsthat according to a fish frying machine for a canned fish processing factory at present, one surface of fish is combined with a conveying belt, so that the hot oil cannot be in full contact with the fish, the quality of the fried fish is low, meanwhile, the fish easily adheres to the conveying belt after being fried, and an operator cannot conveniently take down the fried fish are effectively solved.

Owner:南京溧水高新产业股权投资有限公司

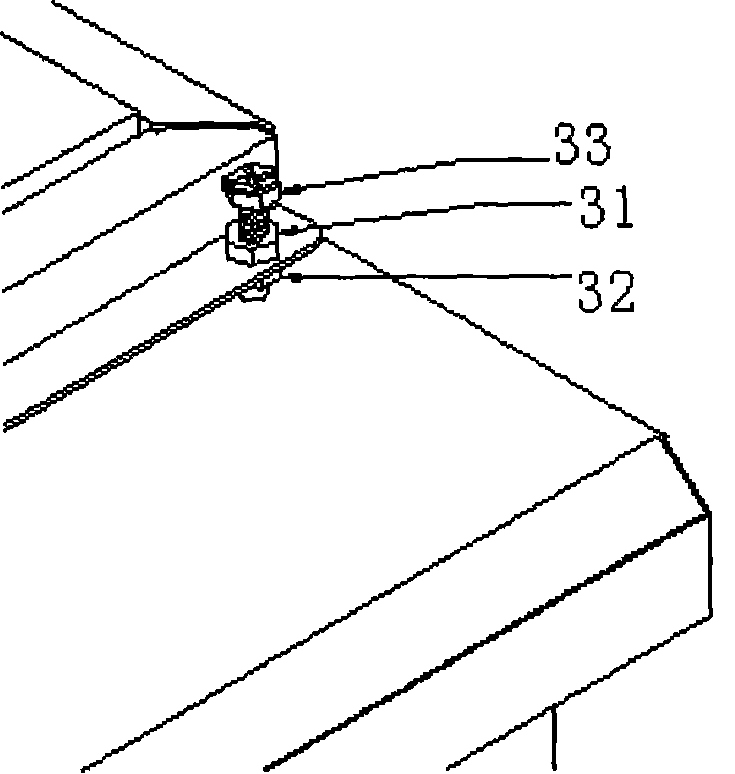

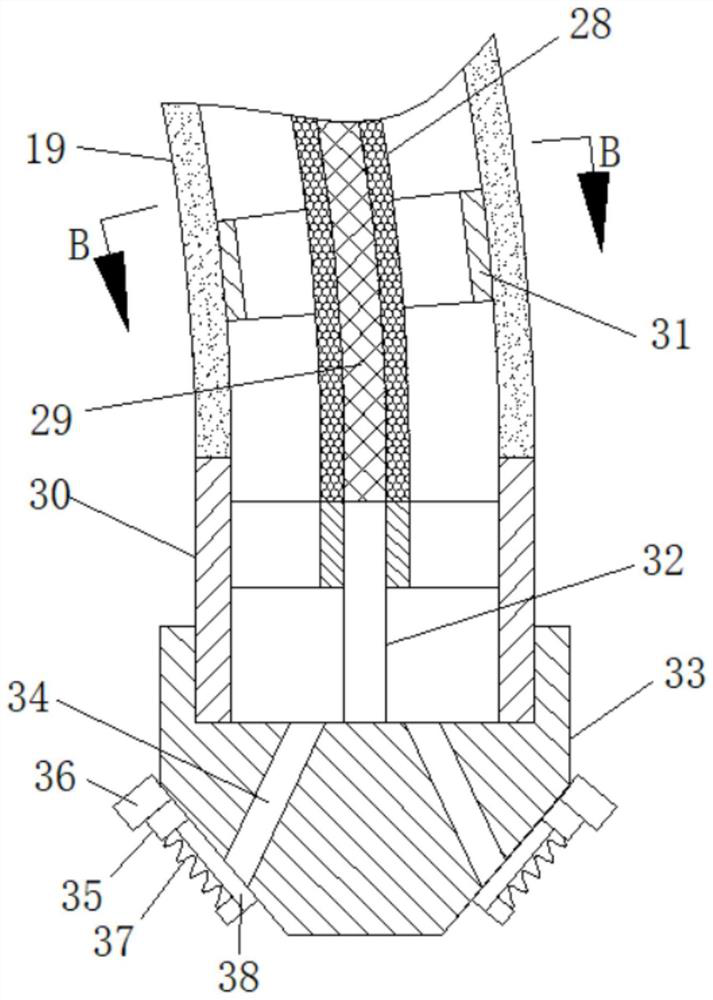

Four-corner structure of dumpling frying furnace pan

Owner:上海酒店设备工程成套南翔厂有限公司

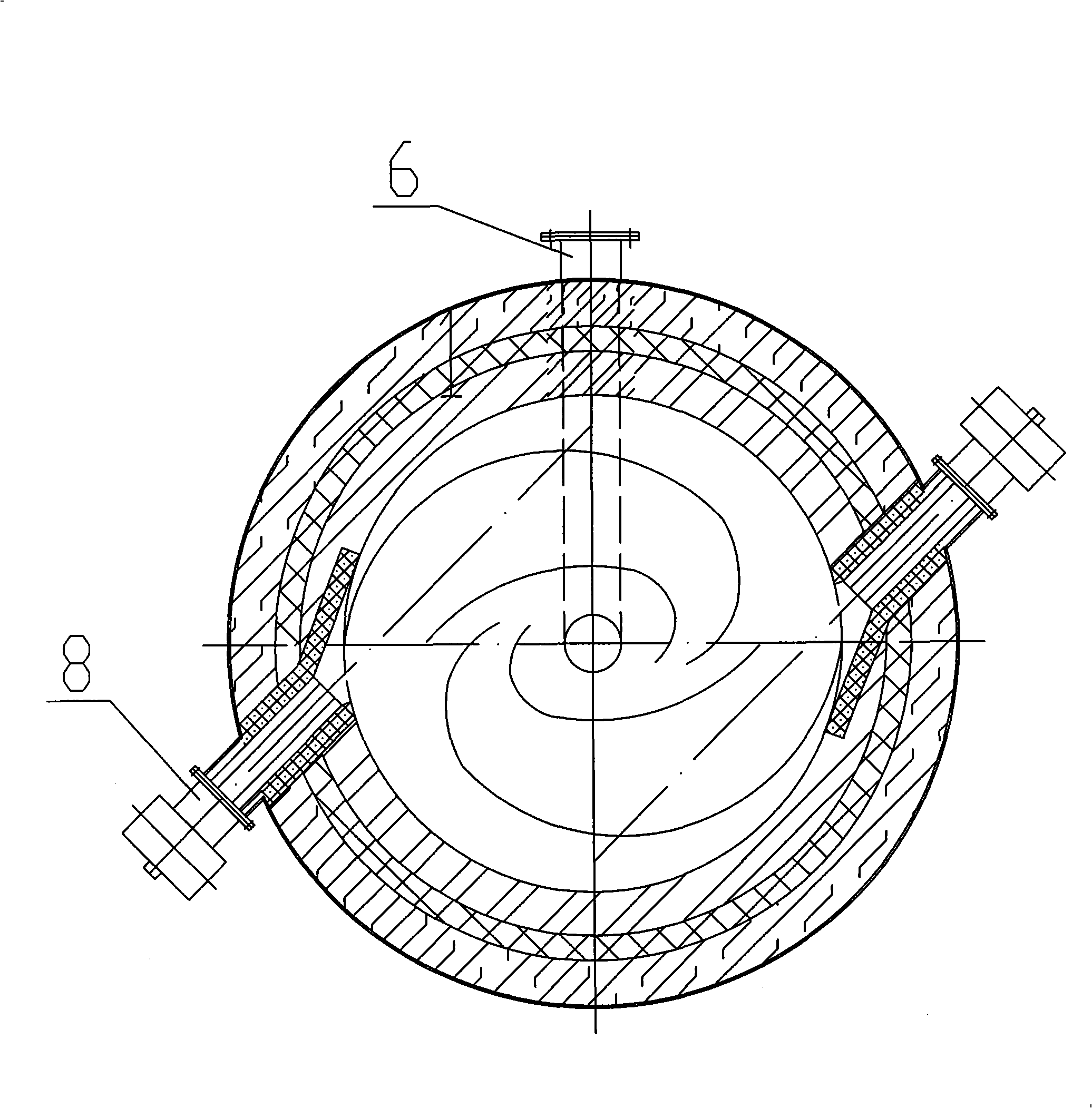

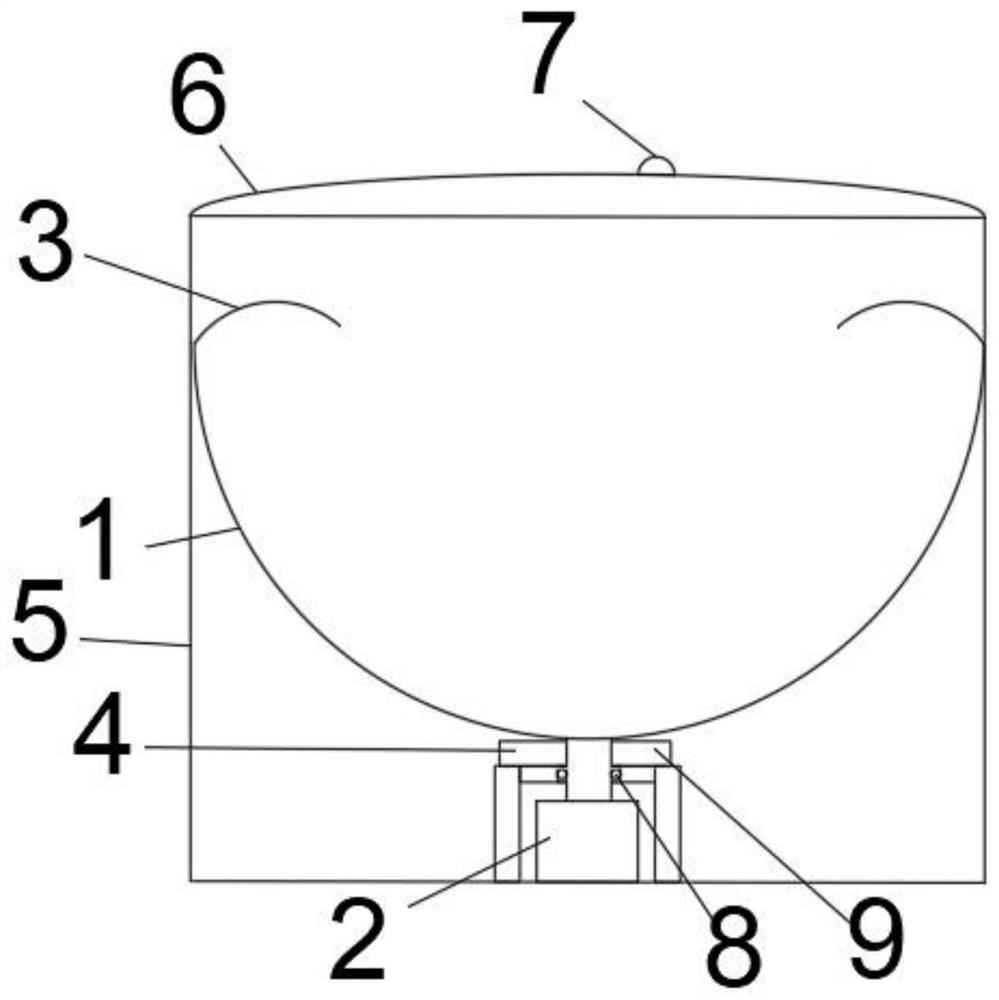

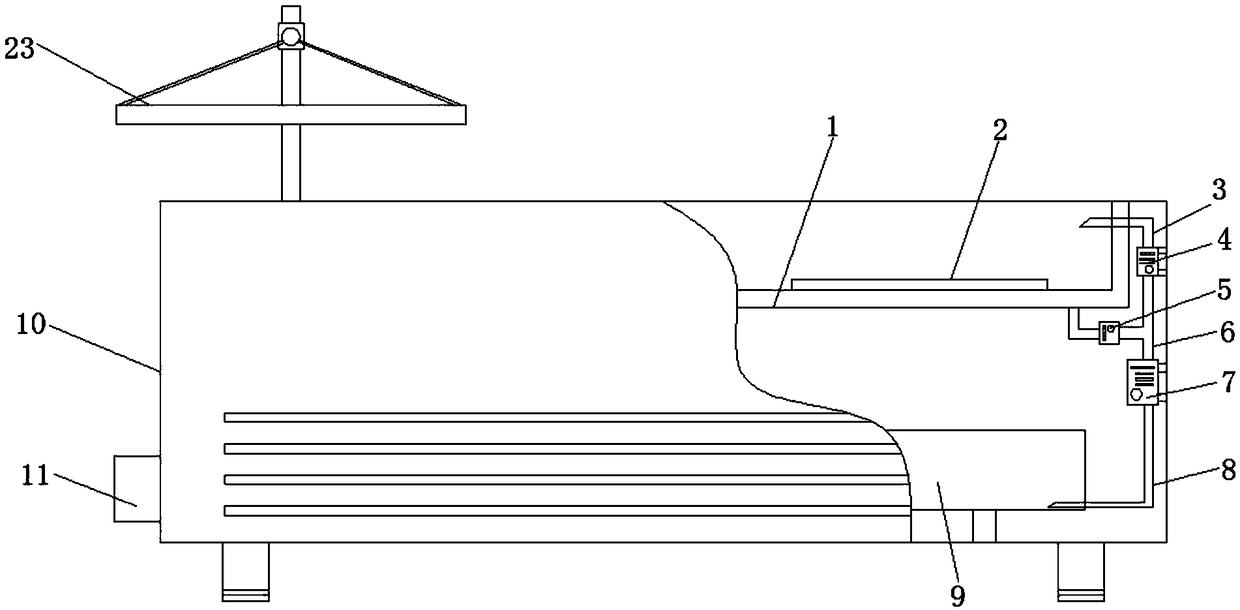

Tea frying device

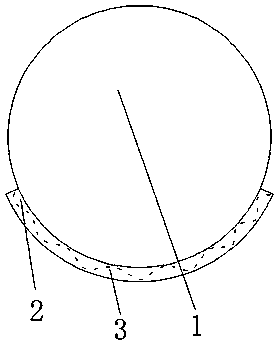

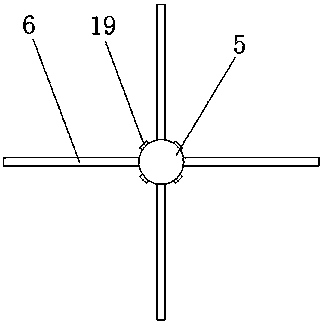

PendingCN114651878AFried evenlyImprove frying qualityPre-extraction tea treatmentCentrifugal forceTea leaf

The invention discloses a tea stir-frying device which comprises a spherical stir-frying pot, and the stir-frying pot is connected with a rotating device. An arc-shaped reverse rolling sheet is fixed at the top of the stir-frying pot, and the tangential direction of the tail end of the reverse rolling sheet directly faces the middle part of the bottom of the spherical stir-frying pot; a heating device is mounted at the bottom of the spherical frying pot; and the stir-frying pot is positioned in the heat preservation box. Tea leaves are raised along with the stir-frying pot under the centrifugal force and then thrown back to the center of the stir-frying pot under the centrifugal force of the reverse rolling sheet, so that circulation is formed, uniform stir-frying of the tea leaves is realized, the tea leaves are not crushed, and the stir-frying quality of the tea leaves is improved.

Owner:石门县达兰茶业有限公司

Air-returning decompression type high temperature hot blast stove capable of dedusting and removing smoke with calandria

Owner:浙江绿峰机械有限公司

Air Fryer and Control Method and Stepless Speed Control Method therefor

PendingUS20220354302A1Optimize dehydrationOptimize fat reduction processDomestic stoves or rangesTemperature control using digital meansAir cycleProcess engineering

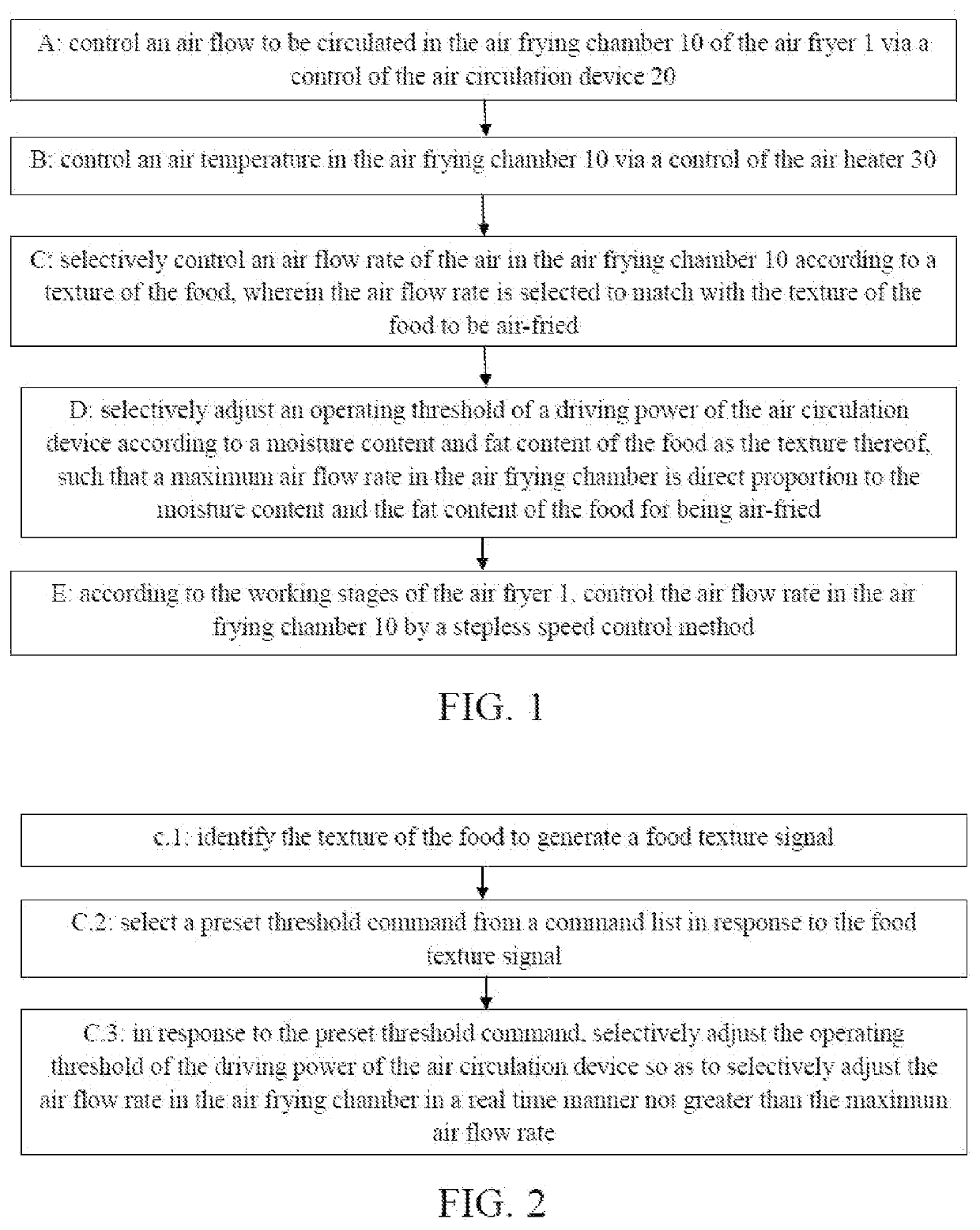

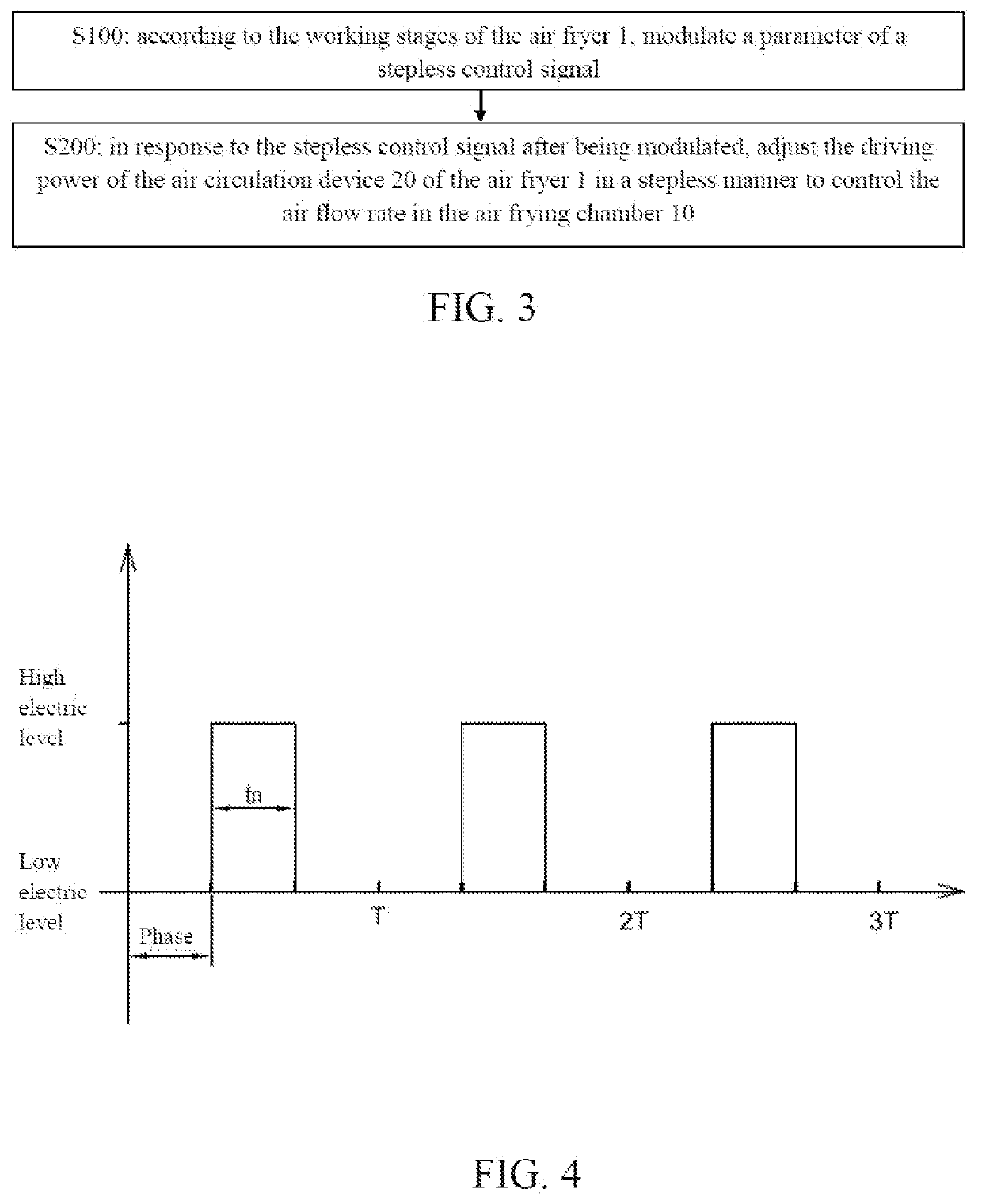

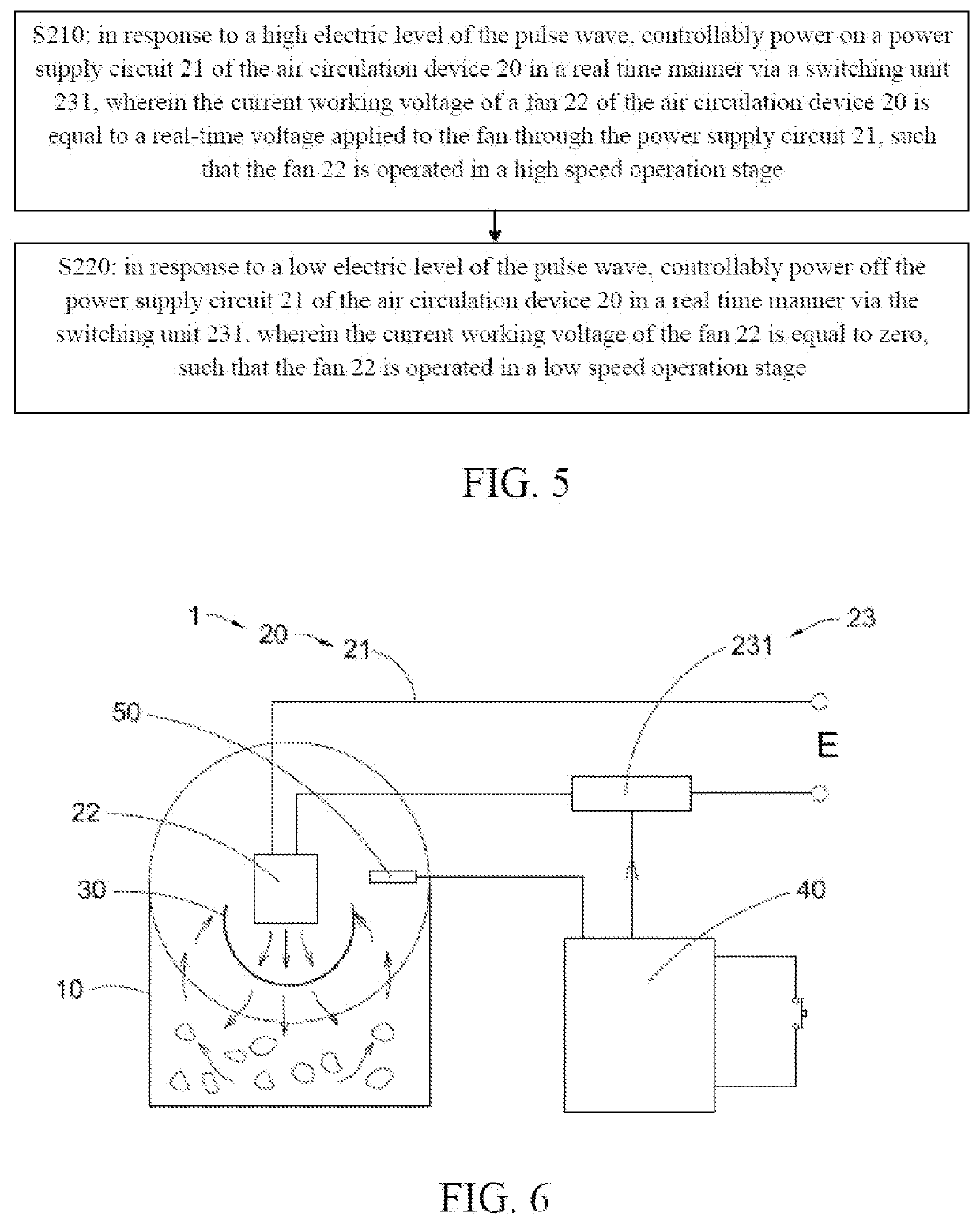

An air fryer includes an air frying chamber for receiving a food therein, an air circulation device and an air heater. A control method for the air fryer includes the steps of controlling an air flow to be circulated in the air frying chamber of the air fryer via a control of the air circulation device, controlling an air temperature in the air frying chamber via a control of the air heater, and selectively controlling an air flow rate of the air in the air frying chamber according to a texture of the food, wherein the air flow rate is selected to match with the texture of the food to be air-fried.

Owner:SHENZHEN HESUNG INNOVATION TECH CO LTD

Combustible liquefied gas high-temperature hot blast furnace

The invention discloses a combustible liquefied gas high-temperature hot blast furnace. The upper end of a combustion furnace is provided with a waste heat air return duct; the waste heat air return duct is communicated with an inner layer hot air chamber of the combustion furnace, and is communicated with a hot air outlet through an outer layer hot air chamber; a hearth of the combustion furnaceis communicated with a hot air outlet chamber of the combustion furnace; the hot air outlet chamber is communicated with a hot air buffer chamber through an air pipe and a draught fan; the hot air buffer chamber is communicated with the waste heat air return duct through a pipeline; in the combustion chamber of the combustion furnace, a plurality of liquefied gas combustion heads are uniformly distributed on a base plate, the base plate is provided with natural air inlet pipes at intervals of the liquefied gas combustion heads; and the bottom end of the air inlet pipe penetrates through the base plate and is open, and the top end of the air inlet pipe extends into and is suspended in the hearth of the combustion furnace. According to the invention, when the natural air inflows, the liquefied gas combustion heads can not be influenced, and accidents caused by the gas leakage due to gas extinguishing can be avoided; and a decompression exhaust pipe enables the pressure generated by the draught fan to be balanced, the liquefied gas combustion heads burn stably, the hearth temperature is constant, and the air outlet temperature of a hot air outlet is constant.

Owner:浙江绿峰机械有限公司

A device for frying tea with screening function

ActiveCN109675787BNot easy to go too farGuaranteed frying qualitySievingPre-extraction tea treatmentElectric machineryStructural engineering

The invention discloses a tea frying device with a screening function, which comprises an installation structure, on which a stir-frying component and a screening component are arranged, the installation structure includes an installation base, two installation brackets are arranged on the installation base, and the upper end of the installation bracket is arranged There are installation platforms, one of which is provided with a mounting rod, and the other is provided with a supporting cylinder, the stir-frying component includes a stir-frying cylinder, and the two ends of the stir-frying cylinder are provided with mounting rings on the outside, the mounting ring and the stir-frying Bearings are arranged between the barrels, one of the two mounting rings is hinged to the upper end of the mounting rod, and the other mounting ring is hinged to the output end of the supporting cylinder, and the stirrer gear is fixed on the outside of the stirrer barrel, and the stirrer gear is fixed on the mounting base. There is a stir-frying motor, and the output shaft of the stir-frying motor is equipped with a stir-frying motor gear, which has a screening function and can prevent the tea leaves from being broken during stir-frying, ensuring the quality of tea forming. At the same time, it can automatically put in and collect tea leaves, reducing labor costs .

Owner:宁强县千山茶业有限公司

Device for frying and processing abyssopelagic fishes

ActiveCN108812734AProblems that affect the energy efficiency of useGuaranteed pureFood processingOil/fat bakingFuel tankEngineering

The invention discloses a device for frying and processing abyssopelagic fishes, which comprises a frying box, wherein one side of the frying box is provided with a material conveying box; the top endof the frying box is provided with a frying inner box; the bottom end of the inner side of the frying inner box is provided with a heating plate; the outer side of the frying inner box is provided with a heat insulation outer box; the bottom end of the frying inner box is provided with an oil outlet pipe, the oil outlet pipe runs through the bottom end of the heat insulation outer box and extendsto the outer side of the heat insulation outer box, the bottom end of the oil outlet pipe is connected with an oil-filtering tank, the inner side of the oil outlet pipe is provided with a third electromagnetic valve, the inner side of the oil-filtering tank is provided with a filter plate, one side of the oil-filtering tank is connected with an oil outlet pump through a pipeline, the top end of the oil outlet pump is connected with a three-way pipe. According to the invention, a second electromagnetic valve, the heat insulation outer box and a return pump are arranged. The problem that when the device is used, the waste heat of the waste oil is difficult for the device to fully utilize, which affects the energy-saving performance of the device, is solved.

Owner:连云港市连云区黄海水产品养殖专业合作社

Mechanical technique for stir-frying flat tea

A technology for mechanically parching the flat tea leaves includes such steps as heating at 185-205 deg.C for 130-170 s, sorting at 160-185 deg.C for 180-240 s, flattening at 150-170 deg.C for 40-80s, polishing at 150-170 deg.C, etc. Its advantages are high quality and high uniformity.

Owner:苏和生

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com