Combustible liquefied gas high-temperature hot blast furnace

A high-temperature hot blast stove, liquefied gas technology, applied in air heaters, fluid heaters, lighting and heating equipment, etc., can solve the problems of gas extinguishing, tea quality reduction, air pollution, etc., to achieve constant air temperature, heat utilization, etc. Fully and improve the effect of frying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

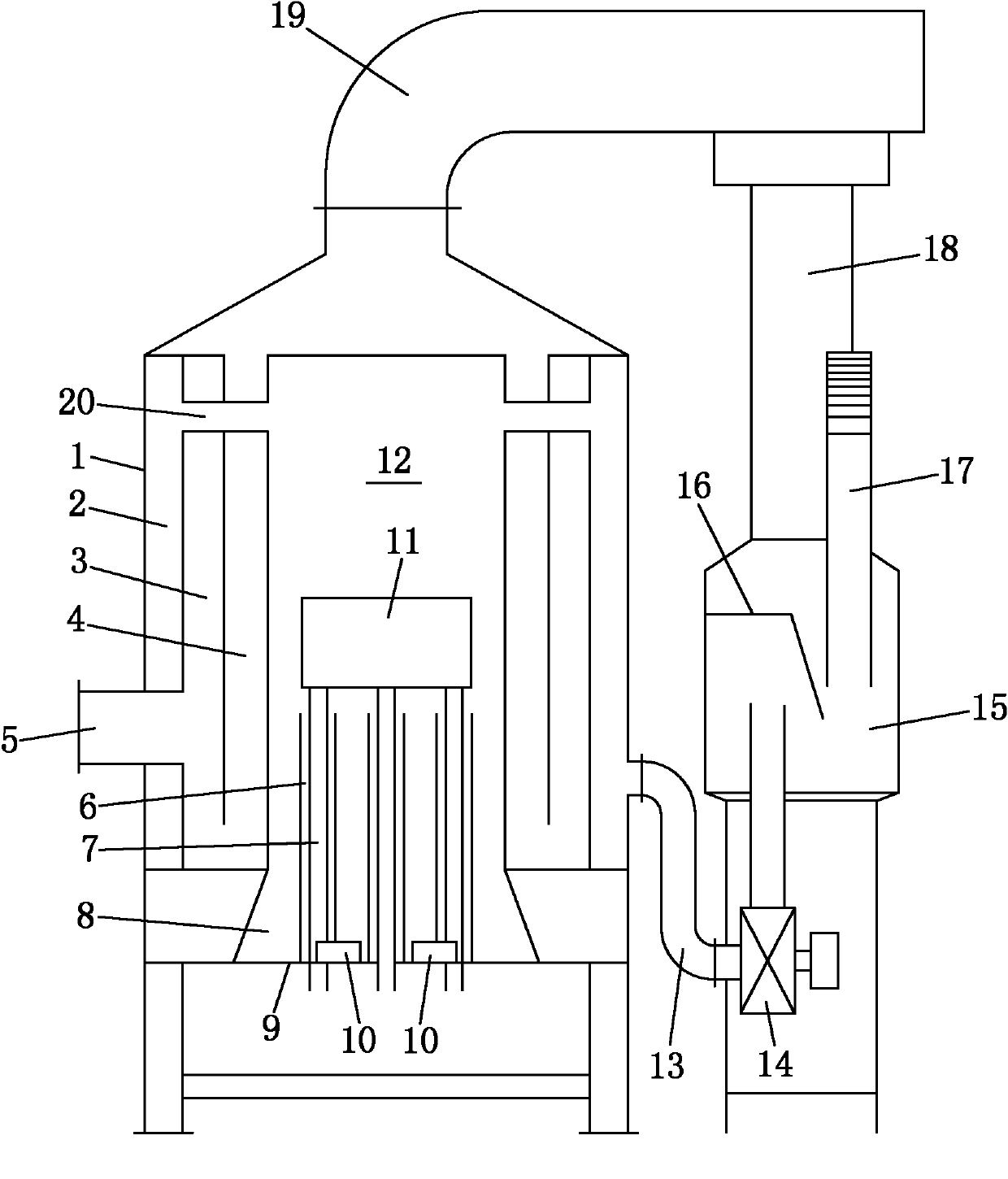

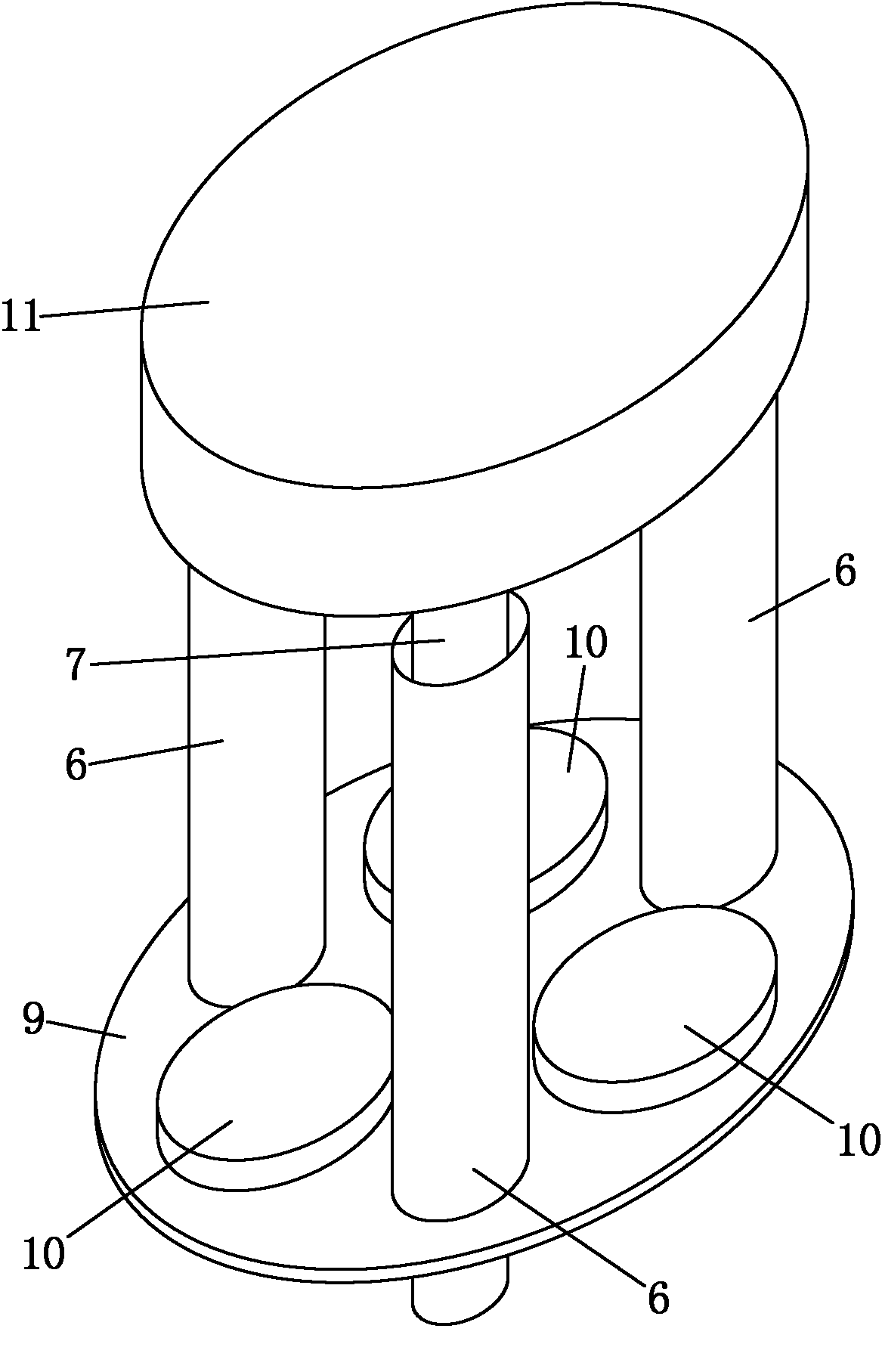

[0013] Example: see figure 1 with figure 2 The waste heat return duct 19 at the upper end of the combustion furnace 1 of the present invention is connected to the inner hot air chamber 4 of the combustion furnace 1, and then connected to the hot air outlet 5 through the outer hot air chamber 3, and the furnace 12 of the combustion furnace 1 passes through the hot air The tube 20 is connected to the hot air outlet chamber 2 of the combustion furnace 1, and the hot air outlet chamber 2 is connected to the hot air buffer chamber 15 through the air pipe 13 and the induced draft fan 14. The hot air buffer chamber 15 is provided with a buffer baffle 16, After the hot air is blocked, the temperature is uniform in the hot air buffer chamber 15 and then enters the waste heat return air duct 19 through the pipe 18. The hot air buffer chamber 15 is also provided with a decompression exhaust pipe 17 to balance the air pressure of the entire device; In the combustion chamber 8 of the combu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com