Full-automatic soaking and stir-frying device for Chinese torreya and stir-frying method thereof

A fully automatic and frying technology, which is applied in general control system, program control, computer control, etc., can solve the problems of scattered processing and uneven quality, and achieve the improvement of electromagnetic heating efficiency, high degree of automation, and improvement of frying quality Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] For the sake of detailing the technical content of the present invention, the purpose achieved and the efficacy, the following will be described in detail in conjunction with the accompanying drawings of the specification.

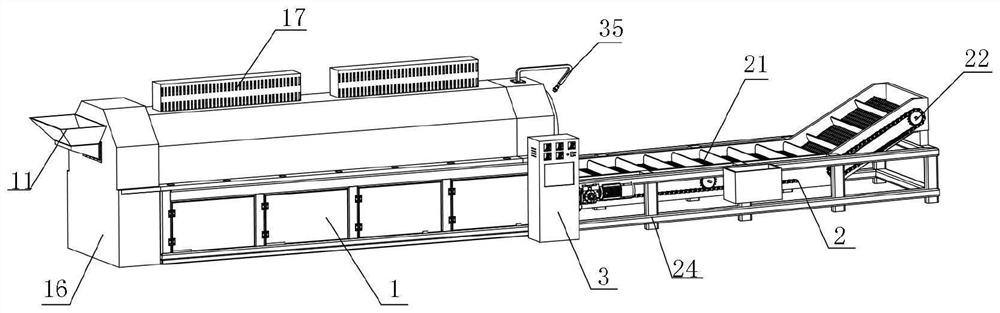

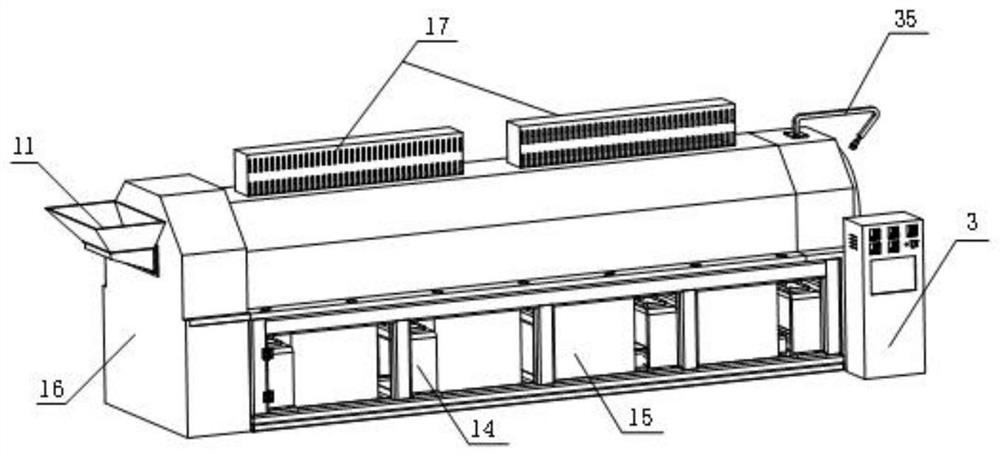

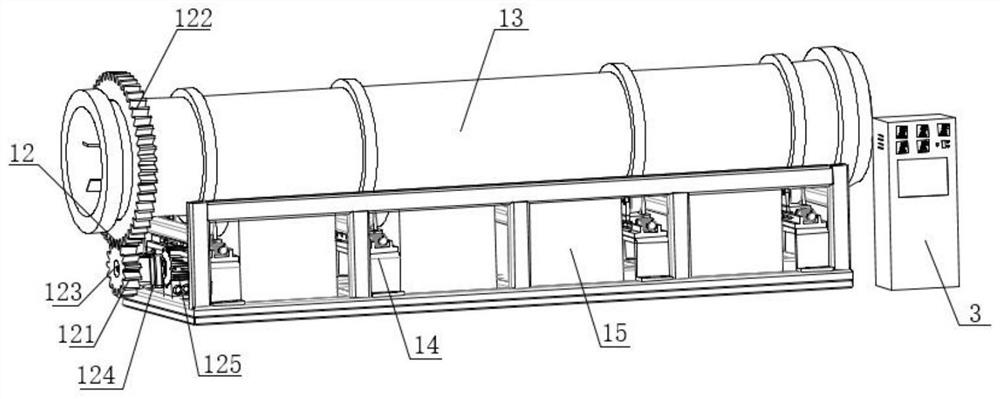

[0036] Fully automatic soaking and stir-frying device for fragrant trees, such as Figure 1 As shown, comprising a frying component 1, a soaking component 2 and a control component 3, the output terminal of the frying component 1 and the input terminal of the soaking component 2 are connected, the control component 3 is located between the frying component 1 and the soaking component 2, and the control component 3 is connected to the frying component 1 and the soaking component 2 respectively through the control circuit. Control component 3 and frying component 1 and soaking component 2 respectively to achieve signal transmission and feedback closed-loop control, and under the control of control component 3 to coordinate the frying component 1 and soakin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com