Walnut stir-frying apparatus

A frying and chestnut frying technology, applied in application, food processing, food science and other directions, can solve the problems of low accuracy of the amount of auxiliary materials, high labor intensity of operators, and low quality of frying chestnut, etc., to improve the quality of frying. The effect of frying efficiency, reducing labor intensity and enhancing frying quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

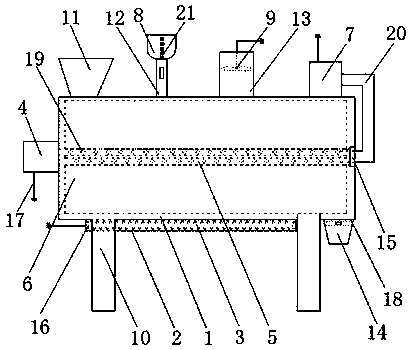

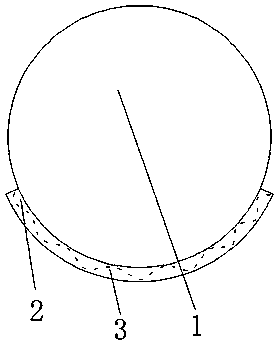

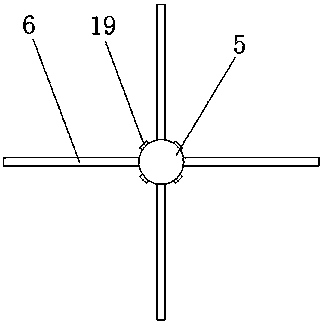

[0017] As attached Figure 1-3 Shown: a chestnut frying device, including frying cylinder 1, heating chamber 2, electric heating wire 3, motor 4, transmission shaft 5, material plate 6, blower 7, auxiliary material cylinder 8 and exhaust fan 9, characterized by : The frying cylinder 1 is set on the support 10, and the frying cylinder 1 is provided with a feed bin 11, an auxiliary material pipe 12, an exhaust pipe 13, and a discharge bin 14, and the frying cylinder 1 is provided Bearing 15, the heating chamber 2 is provided at the bottom of the frying cylinder 1, a heating block 16 is provided in the heating chamber 2, and a power cord 17 is provided on the heating block 16, and the heating wire 3 is provided on the heating block Between 16 and the heating block 16, the motor 4 is arranged at one end of the frying drum 1, and a power cord 17 is arranged on the motor 4. One end of the transmission shaft 5 is arranged in the shaft sleeve 15, and the other end passes through After...

Embodiment 2

[0023] As attached Figure 4 Shown: a chestnut frying device, including frying cylinder 1, heating chamber 2, electric heating wire 3, motor 4, transmission shaft 5, material plate 6, blower 7, auxiliary material cylinder 8 and exhaust fan 9, characterized by : The frying cylinder 1 is set on the support 10, and the frying cylinder 1 is provided with a feed bin 11, an auxiliary material pipe 12, an exhaust pipe 13, and a discharge bin 14, and the frying cylinder 1 is provided Bearing 15, the heating chamber 2 is provided at the bottom of the frying cylinder 1, a heating block 16 is provided in the heating chamber 2, and a power cord 17 is provided on the heating block 16, and the heating wire 3 is provided on the heating block Between 16 and the heating block 16, the motor 4 is arranged at one end of the frying drum 1, and a power cord 17 is arranged on the motor 4. One end of the transmission shaft 5 is arranged in the shaft sleeve 15, and the other end passes through After th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com