Peanut stir-frying machine

A stir-frying machine and stir-frying technology, applied in the direction of fat generation, fat oil/fat production, food processing, etc., can solve the problems of low frying efficiency, poor frying quality of peanut stir-frying machine, etc., so as to improve the frying efficiency, The effect of saving electricity and heating evenly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing embodiment:

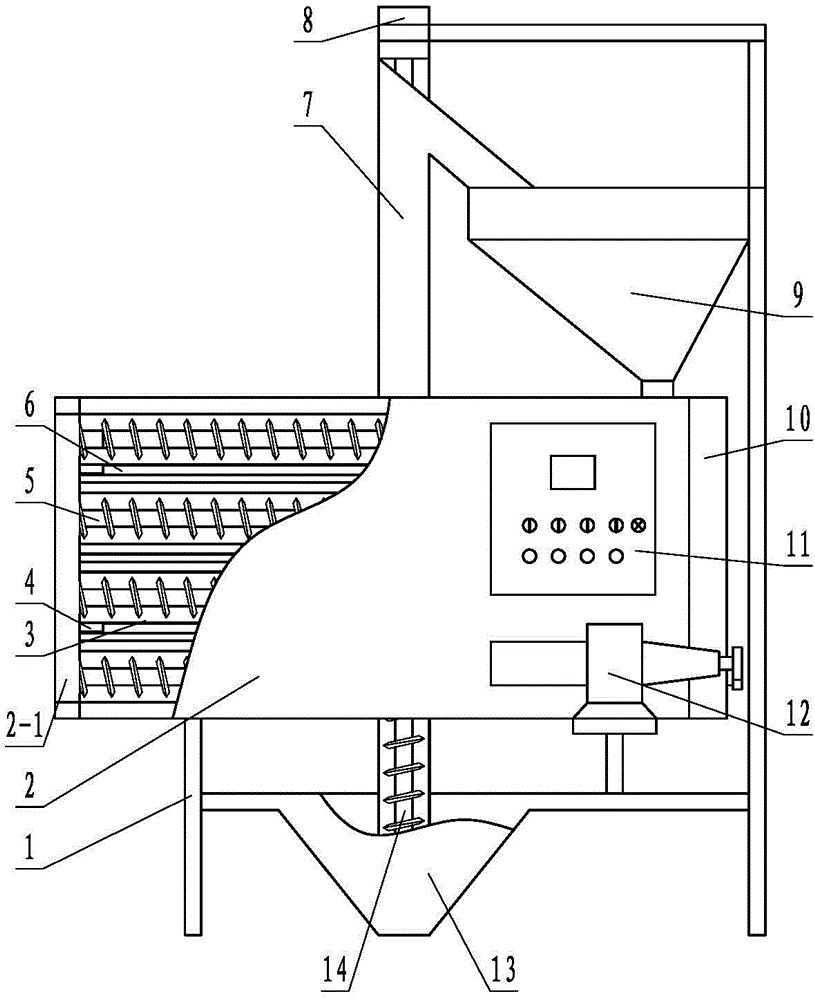

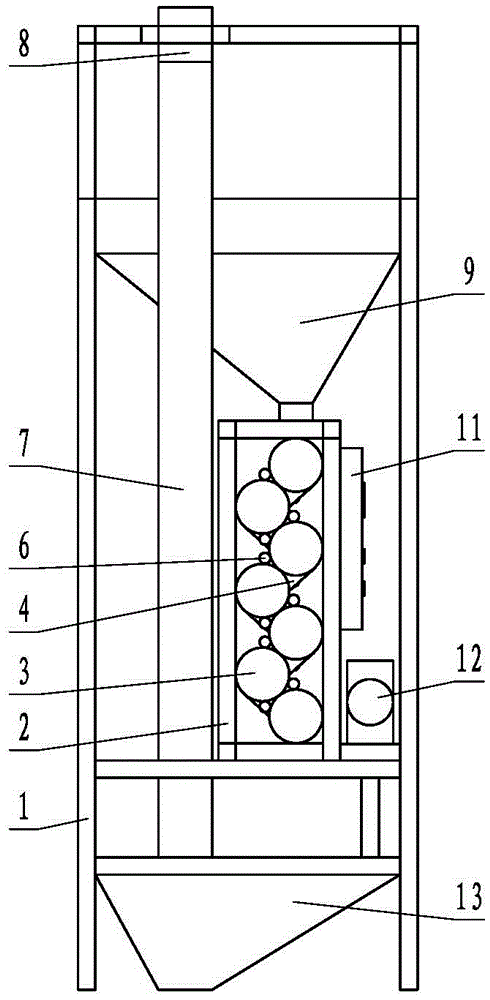

[0015] figure 1 with figure 2 The peanut frying machine shown mainly includes a frame 1, an incubator 2, a frying barrel 3, a heating pipe 6, a feed hopper 9, a transmission device, a motor 12, a storage box 13, a lifting feeding device and a control box 11, Wherein, the incubator 2, the feeding hopper 9 and the motor 12 are fixedly installed on the frame 1, and the incubator 2 is fixed with a plurality of stir-fry barrels 3 arranged staggered up and down, and the stir-fry barrels 3 are arranged horizontally, and the adjacent fry barrels 3 butt against each other; the feed hopper 9 is connected to the feed port of the top stir-fry barrel 3, and the discharge port and the feed port of each stir-fry barrel 3 are respectively arranged on the cylinder wall near both ends, and the feed port It is located on the upper part of the stir-fry barrel 3, and the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com