Process implementation method for improving quality of tobacco stalks by using steam explosion and anaerobic treatment

A realization method, an anaerobic treatment technology, applied in the treatment of tobacco, application, tobacco, etc., can solve the problems of long treatment period, complicated process, poor moisture regain effect of dry tobacco stems, etc., and achieve the effect of shortening the treatment period and improving the treatment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

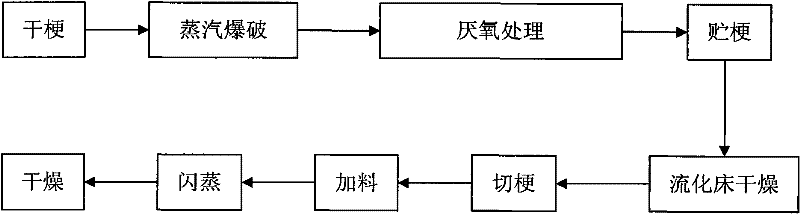

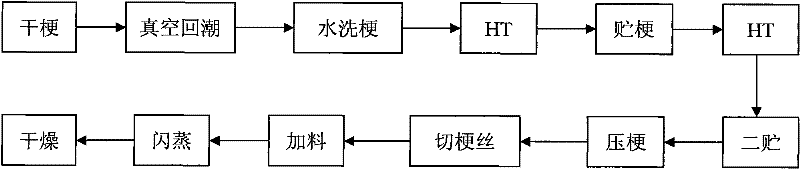

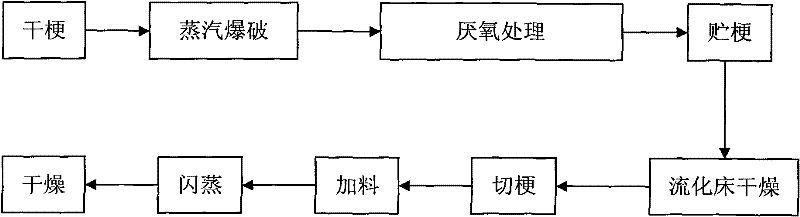

[0020] from figure 1 and figure 2 It can be seen from the comparison that the process realization methods for improving the quality of tobacco stems, including steam explosion, anaerobic treatment and fluidized bed drying process, mainly improve and optimize the existing cut stem treatment process. This method applies steam explosion, anaerobic treatment and fluidized bed drying. The chemical bed drying replaces the vacuum dampening, washing stems, HT (tunnel-type shredded silk dampening machine) and stem pressing processes of the existing shredded stems process.

[0021] The process realization method comprises the following steps:

[0022] (1) First, dry tobacco stems are steam-exploded. After steam explosion, the moisture content of the tobacco stems is above 60%, and the temperature is 40-50°C, making the overall environment weakly acidic and providing suitable environmental conditions for anaerobic treatment.

[0023] (2) Then perform anaerobic treatment on the blasted...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com