Method for realizing a process for improving tobacco stem quality by applying steam explosion and microwave radiation technology

A method of realization, a technology of microwave radiation, applied in the field of tobacco leaf and stem processing, can solve the problems of poor moisture regain effect, long processing cycle, and large space occupation of dry tobacco stems, and achieve the goal of optimizing the existing shredded stem processing technology and reducing process costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

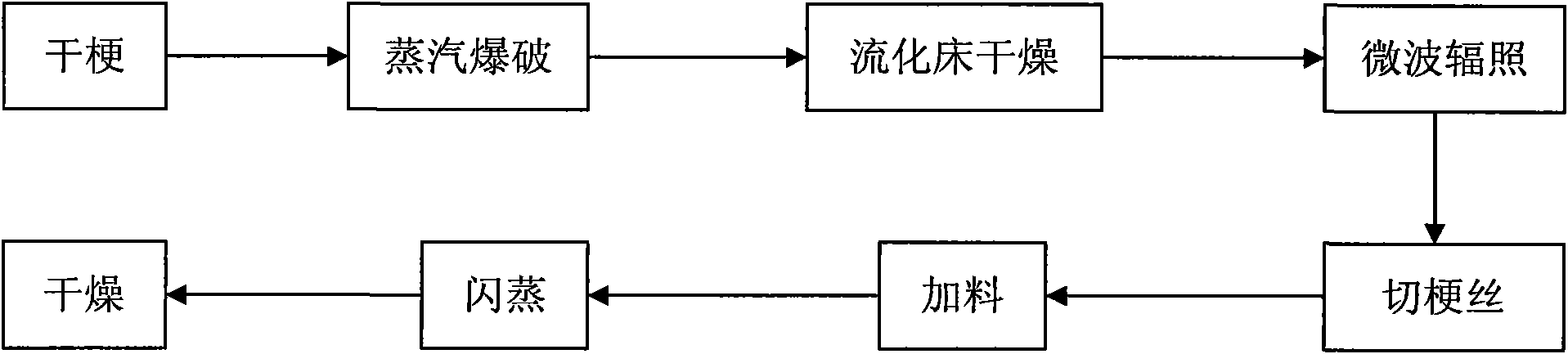

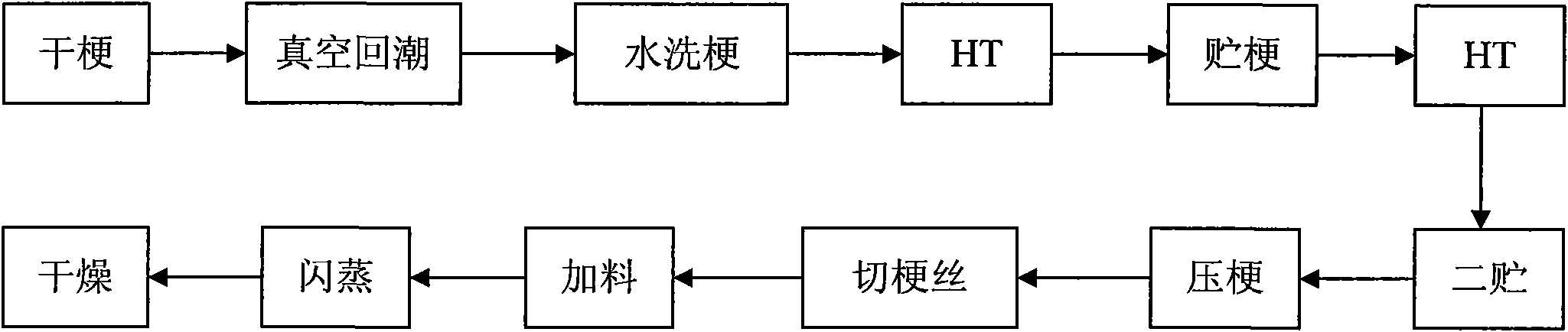

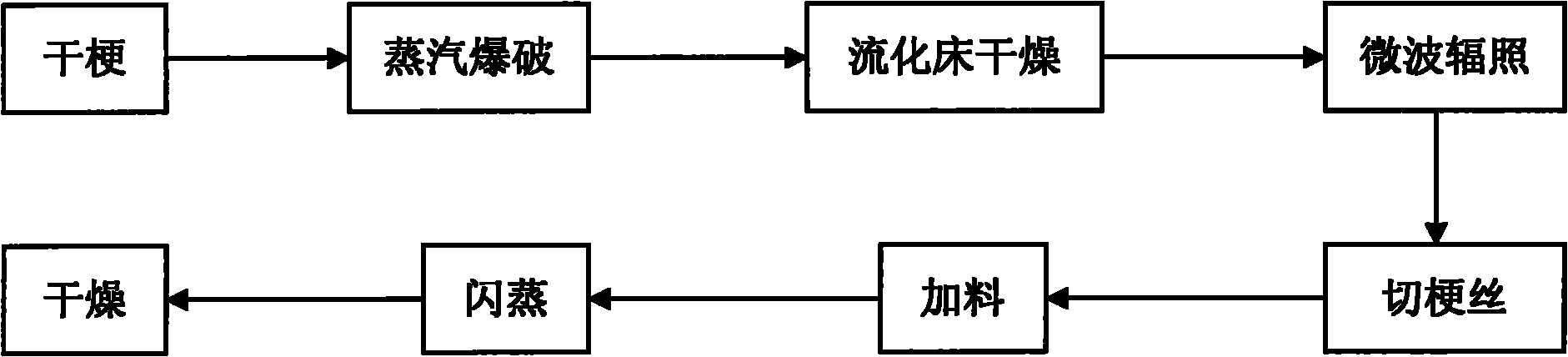

[0019] combine figure 1 , figure 2 The present invention is further described.

[0020] A process realization method for improving the quality of tobacco stems, comprising the following steps:

[0021] (1) first carry out steam explosion to the tobacco stem, then remove excess moisture by fluidized bed drying, and control the moisture content of the tobacco stem at 20-30%;

[0022] (2) Utilize a microwave irradiator to carry out microwave irradiation to the tobacco stem after blasting and drying;

[0023] (3) Shred the irradiated tobacco stems and enter the existing shredded stem processing flow;

[0024] (4) The shredded stems are fed, flashed and dried as one of the raw materials for cigarette production.

[0025] from figure 1 figure 2 It can be seen that the dry stems are steam-exploded first, and then the excess moisture is removed by fluidized bed drying, and the moisture content of the tobacco stems is controlled at 20-30%; then the tobacco stems enter the micro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com