Masonry method of permanent ladle layer by using magnesia carbon bricks

A permanent layer and magnesia-carbon brick technology, which is applied in the direction of casting molten material containers, metal processing equipment, casting equipment, etc., can solve the problems of hidden dangers in production safety, short life, inability to compress the permanent layer bricks of the ladle, etc., and achieve improvement Safety and the effect of preventing leakage accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

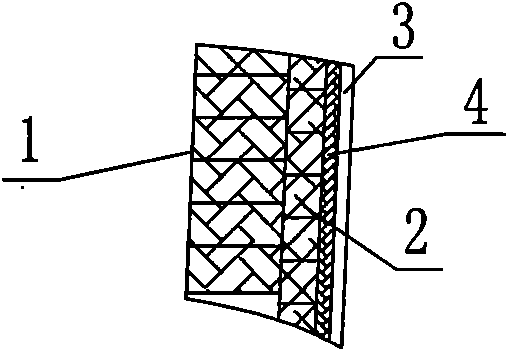

[0014] Such as figure 1 As shown, the method for using magnesia-carbon bricks to build the permanent layer of the ladle according to the present invention selects the existing magnesia-carbon bricks used for the working layer 1 of the ladle to build the permanent layer 2 of the ladle; when building, according to the design size and thickness requirements Choose fan-shaped flat-laying magnesia-carbon bricks and adopt the flat-laying method. First, use the permanent layer ladle castable to knot the bottom permanent layer to the specified thickness, and then use 0-3mm bottom packing material on the knotted bottom permanent layer. Leveling, on the leveled bottom permanent layer, close to the wall insulation layer 4, one ring and one ring, and build from bottom to top; the permanent layer is built by flat laying method, namely:

[0015] a. Place the first fan-shaped flat-laying magnesia-carbon brick horizontally, with its wedge-shaped bottom facing downward and its wide end facing ...

Embodiment 2

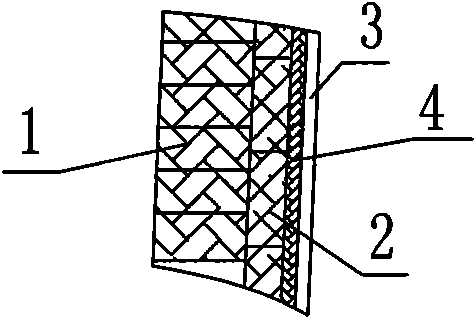

[0021] Such as figure 2 As shown, the method for using magnesia-carbon bricks to build the permanent layer of the ladle according to the present invention selects the existing magnesia-carbon bricks used for the working layer 1 of the ladle to build the permanent layer 2 of the ladle; when building, according to the design size and thickness requirements Choose vertical wedge-shaped magnesia-carbon bricks, and the permanent layer adopts the vertical method, namely:

[0022] a. Place the first vertical wedge-shaped magnesia-carbon brick upright, with the wedge-shaped bottom facing downwards and the wide end facing the ladle wall insulation layer 4;

[0023] b. Align one side of the second vertical wedge-shaped magnesia-carbon brick and build it close to one side of the first block. The wedge-shaped bottom surface is still downward, and the wide end faces the ladle wall insulation layer 4;

[0024] c. Repeat step b in turn to finish building the first ring layer and make the d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com