Electronic parts installation apparatus

A technology for electronic component installation and electronic components, which is applied in the direction of electrical components, electrical components, etc., can solve problems such as the detour of the mounting head and the lengthening of the operation cycle time, and achieve the effects of suppressing errors, improving manufacturing efficiency, and suppressing bending or twisting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0049] (overall structure of the embodiment)

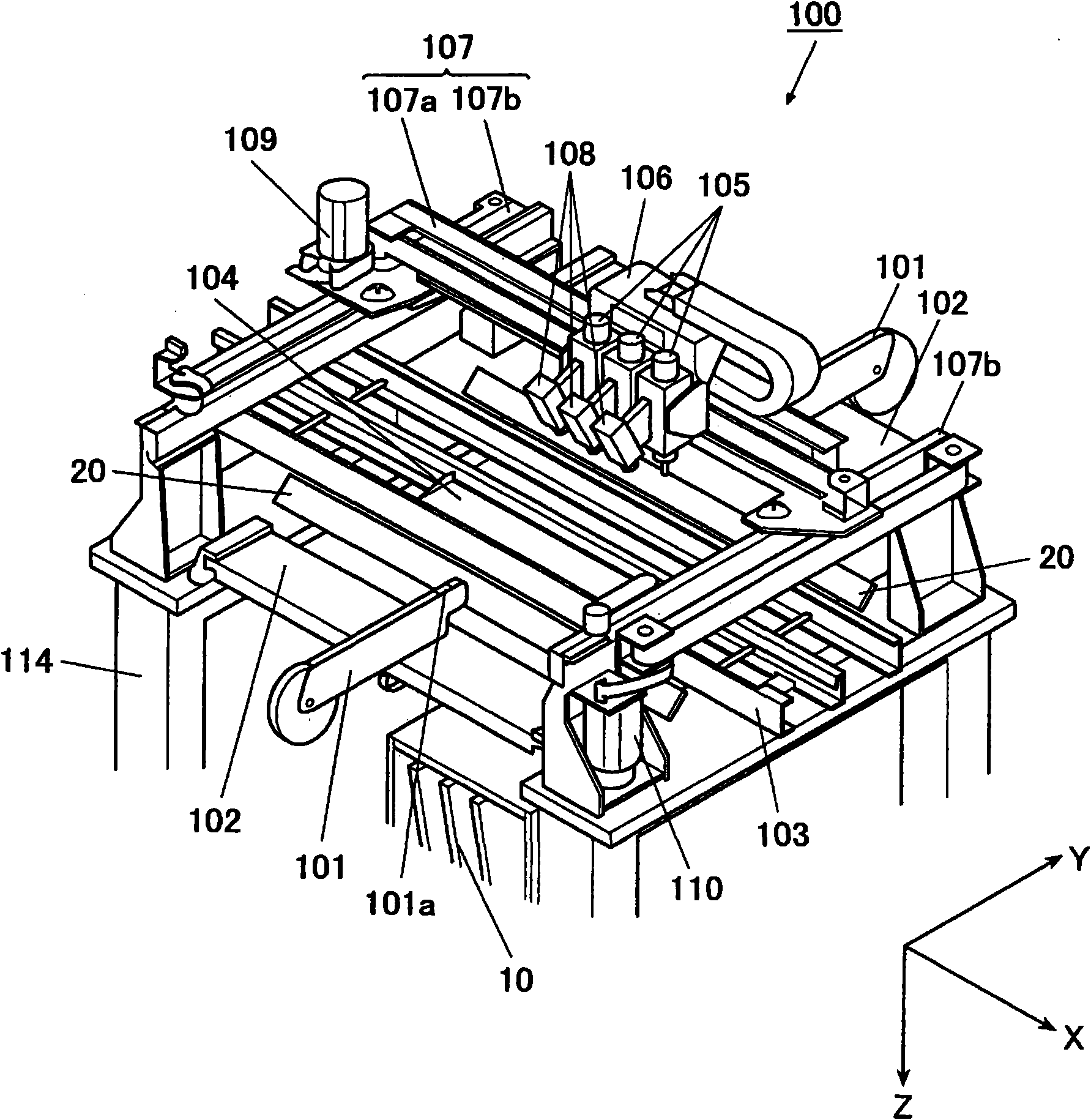

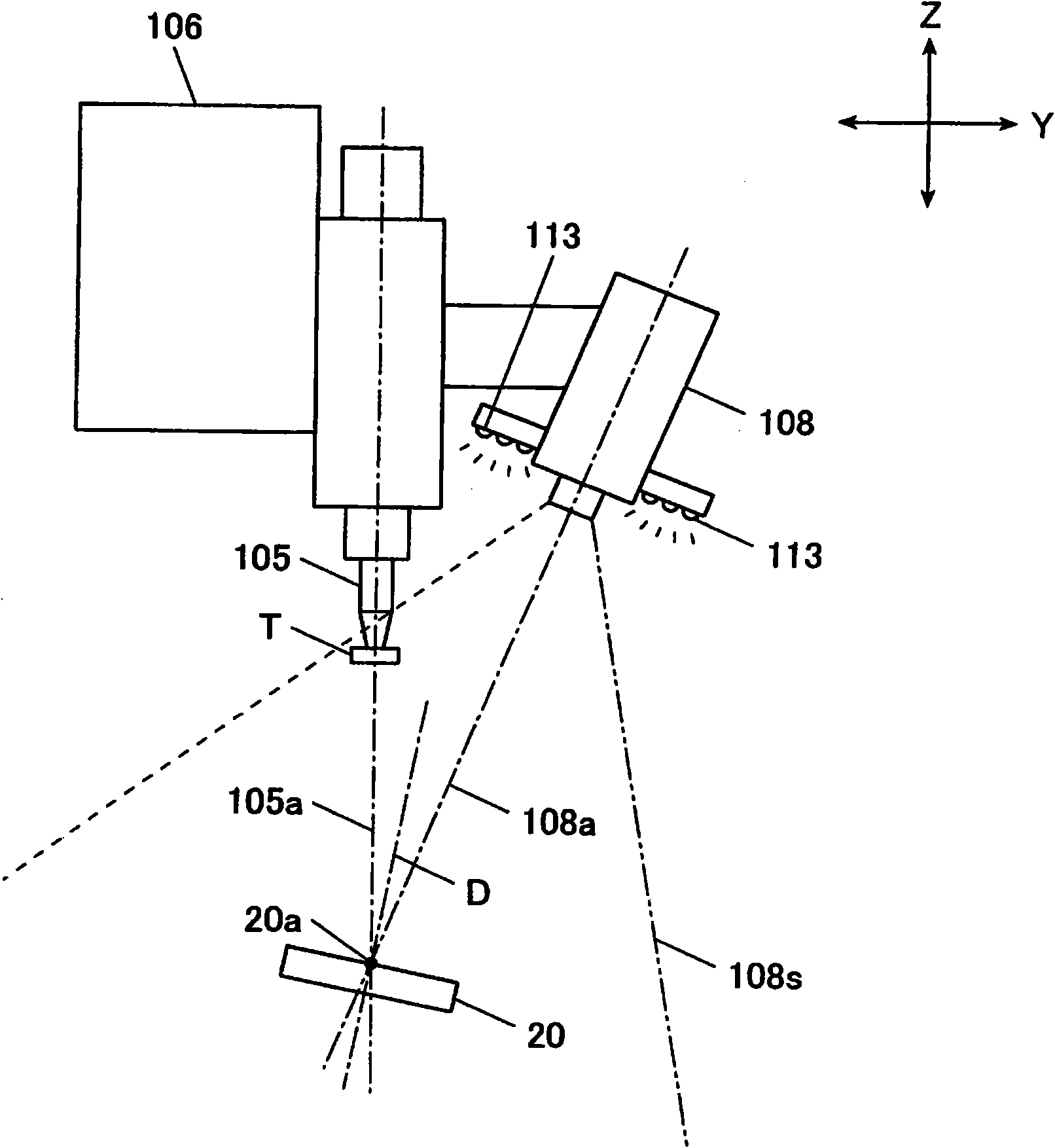

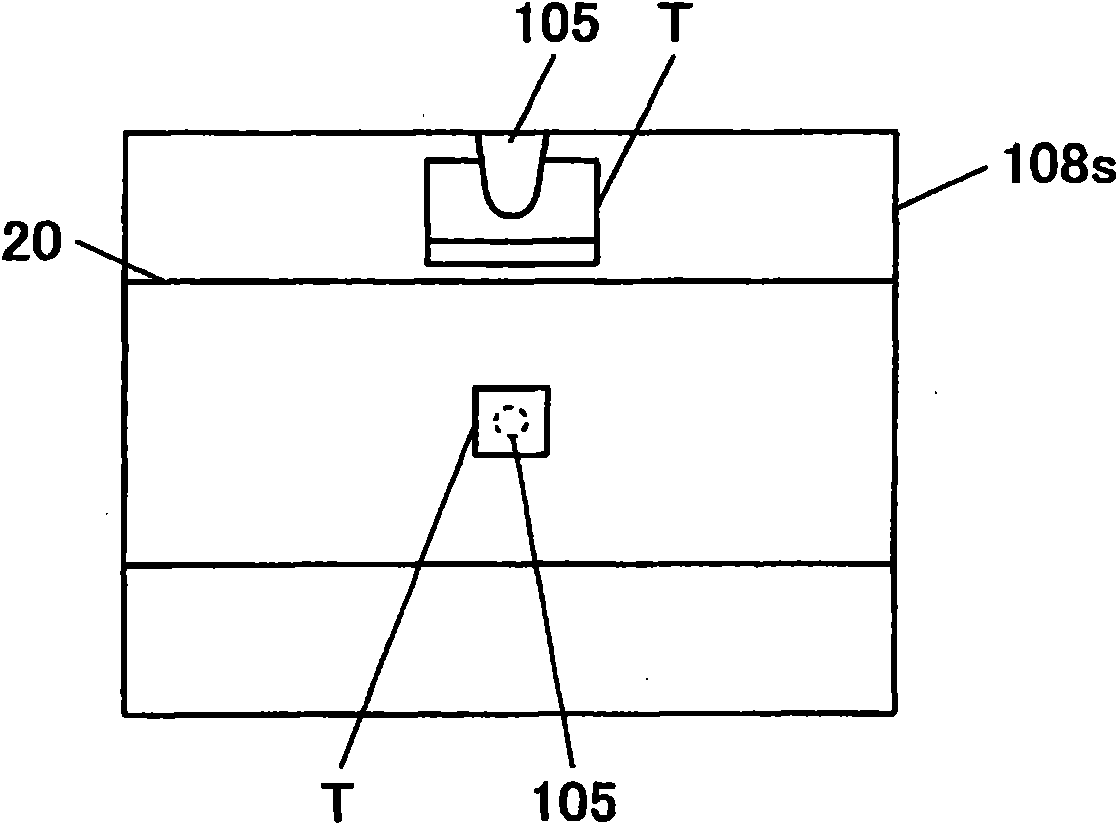

[0050] based on Figure 1 to Figure 11 Embodiments of the present invention will be described. Hereinafter, as shown in the figure, let the two directions perpendicular to each other on the horizontal plane be the X-axis direction (substrate conveying direction) and the Y-axis direction (direction perpendicular to the substrate conveying direction), respectively, and The vertical direction is defined as the Z-axis direction. The electronic component mounting apparatus 100 mounts various electronic components on the substrate, such as figure 1 As shown, there are two sets of component supply units, which are composed of a plurality of electronic component suppliers 101 for supplying electronic components to be mounted, and a supplier storage box 102 for arranging and holding a plurality of electronic component suppliers 101; Unit 103, which transports the substrate along the X-axis direction; a substrate holding unit 104, which...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com