Aircraft with aircraft cooling system

A technology of cooling system and aircraft, applied in the cooling system of power plant, aircraft parts, aircraft control and other directions, to achieve the effect of excellent cooling capacity and large heat exchange area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

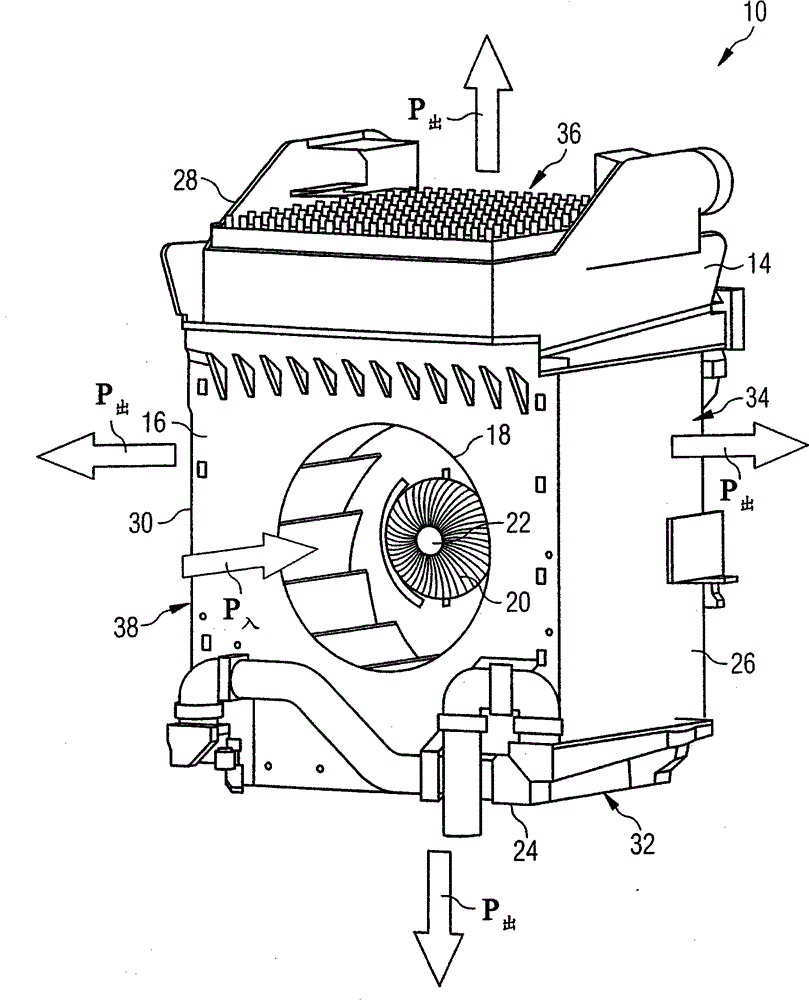

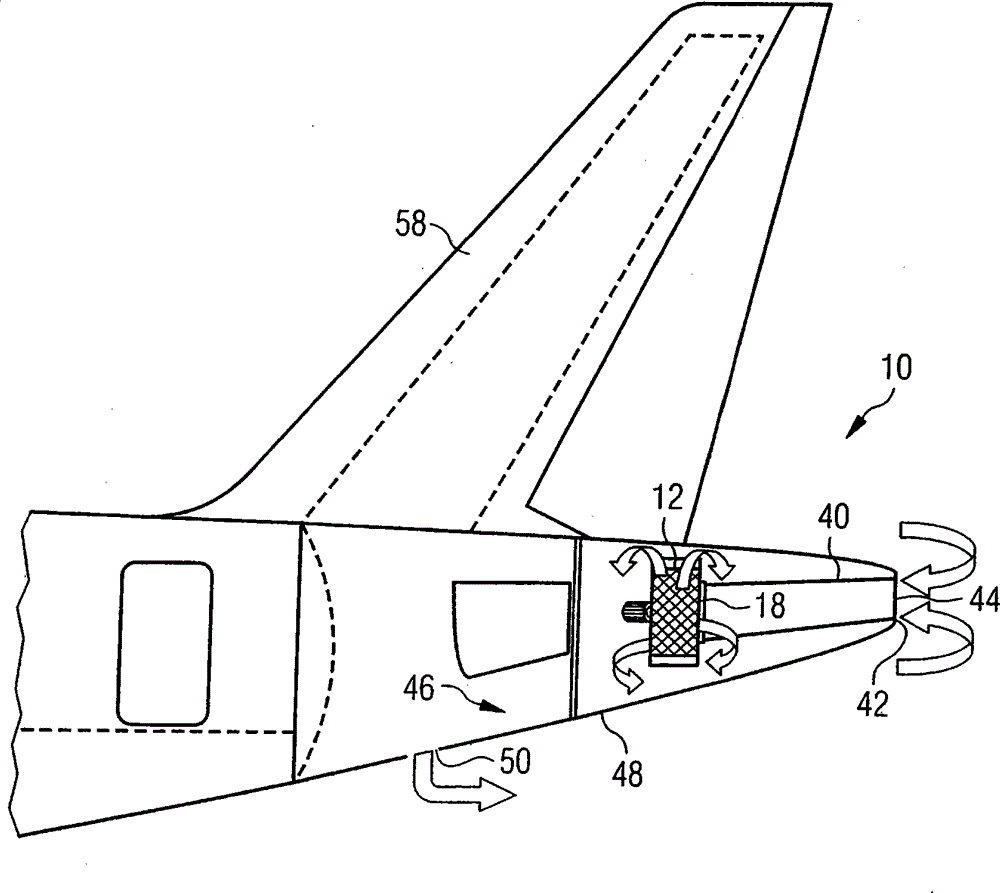

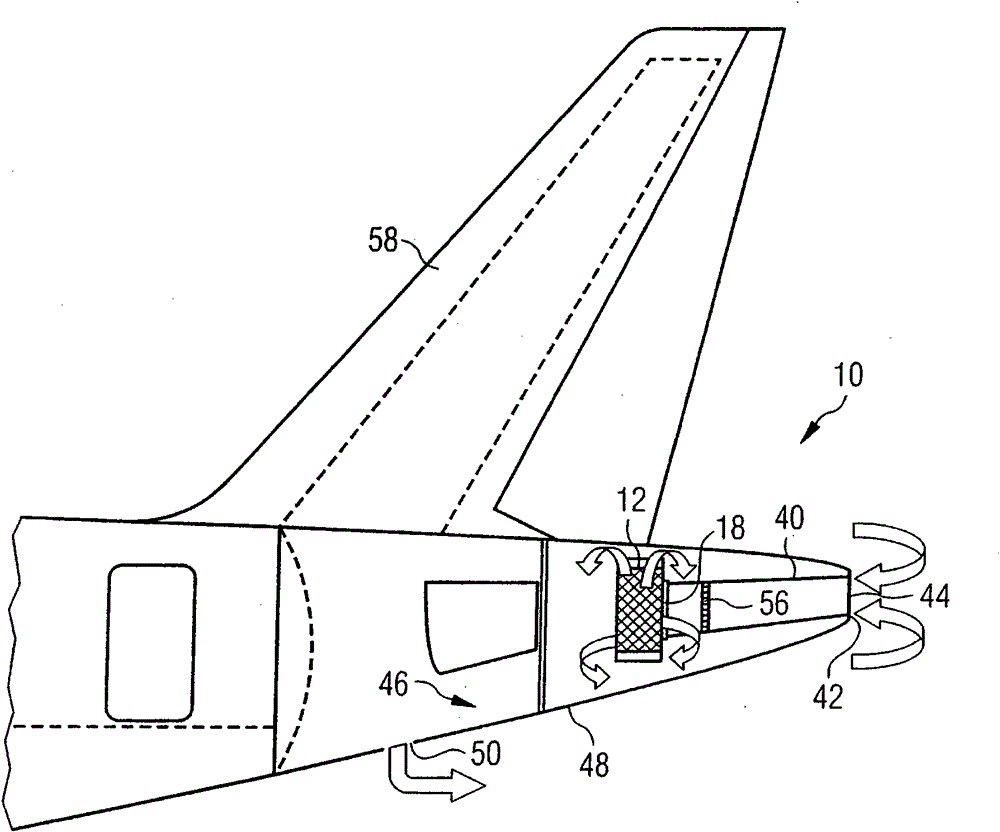

[0032] figure 1 shown suitable for use in Figure 2 to Figure 5 A cooling element 12 in an aircraft cooling system 10 is shown. The cooling element 12 includes a substantially cuboidal housing 14 . Cooling air inlets 18 are provided on the front side surface 16 of the cooling element 12 . A radial fan 20 is arranged in the region of the cooling air inlet 18 . A radial fan 20 is used in the direction of the cooling air inlet 18 (e.g. figure 1 Indicated by the arrow P in) sucking cooling air, and then radially outward with respect to the rotation axis 22 of the radial flow fan 20 (as figure 1 Shown by the arrow P in) to push the cooling air. On the side surfaces 24 , 26 , 28 , 30 of the cooling element 12 adjoining the front side surface 16 are provided heat exchangers 32 , 34 , 36 , 38 respectively. Cooling air flowing into the housing 14 of the cooling element 12 through the cooling air inlet 18 flows through the heat exchangers 32 , 34 , 36 , 38 and thereby transfers...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com