Polyether polymer composition and sheet

A polymer and composition technology, applied in the field of polyether polymer composition, can solve the problems of insufficient electrical conductivity, agglomeration of conductive fillers, deterioration of dispersibility, etc., and achieve excellent long-term stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0079] Hereinafter, the present invention will be further described based on detailed examples, but the present invention is not limited to these examples. In addition, in the following, "parts" are based on weight unless otherwise specified. In addition, tests and evaluations are as follows.

[0080] (1) Number of repeating units, number-average molecular weight (Mn), and molecular weight distribution (Mw / Mn) of polyether-based polymers

[0081] The number-average molecular weight (Mn) and molecular weight distribution (Mw / Mn) of polyether-based polymers that do not contain cationic groups can be determined as polyphenylene by gel permeation chromatography (GPC) using tetrahydrofuran as a solvent. The number average molecular weight (Mn) and molecular weight distribution (Mw / Mn) of the polyether polymer were measured in terms of ethylene. In addition, HLC-8320 (manufactured by Tosoh Corporation) was used as a measuring device, a column in which two TSKgelα-M (manufactured b...

manufacture example 1

[0099] (Synthesis of polyether polymer A)

[0100] Into a glass reactor equipped with a stirrer replaced with argon, 0.161 g of tetra-n-butylammonium bromide and 100 ml of toluene were added, followed by cooling to 0°C. Next, what dissolved 0.086 g of triethylaluminum (1.5 equivalent with respect to tetra-n-butylammonium bromide) in 10 ml of n-hexane was added, and it was made to react for 15 minutes, and the catalyst composition was obtained. 35.0 g of epichlorohydrin was added to the obtained catalyst composition, and the polymerization reaction was performed at 0 degreeC. After the polymerization reaction started, the viscosity of the solution gradually increased. After reacting for 12 hours, a small amount of water was injected into the polymerization reaction solution to stop the reaction. The obtained polymerization reaction solution was washed with a 0.1N aqueous hydrochloric acid solution to deash the catalyst residue, and after washing with ion-exchanged water, the ...

manufacture example 2

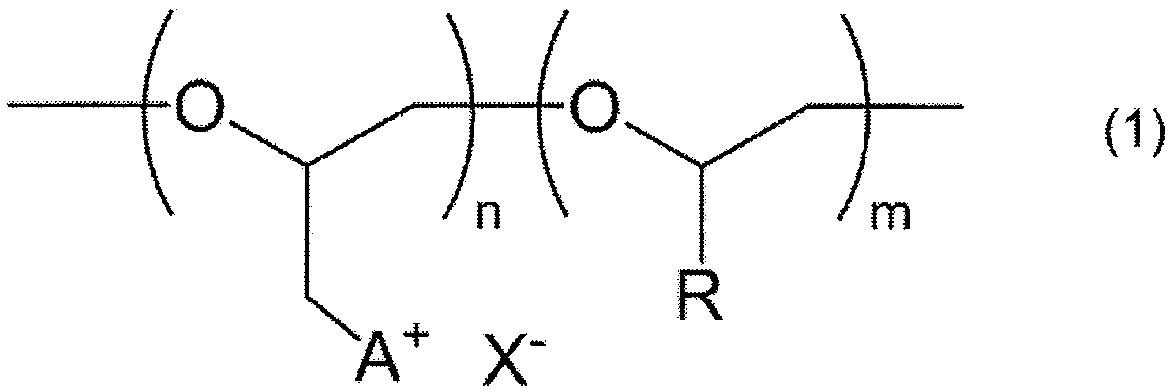

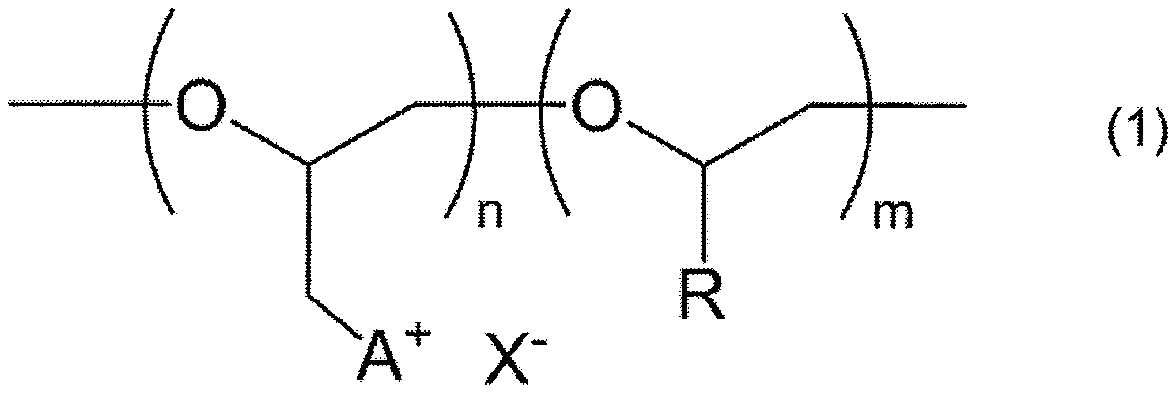

[0102] (Synthesis of Polyether Polymer B Containing an Imidazolium Structure)

[0103] 5.0 g of the polyether-based polymer A obtained in Production Example 1, 12.1 g of 1-methylimidazole, and 10.0 g of acetonitrile were added to a glass reactor equipped with a stirrer replaced with argon, and heated to 80°C. After making it react at 80 degreeC for 48 hours, it cooled to room temperature, and stopped reaction. After washing the obtained reactant with an equal weight mixed solution of toluene / methanol / water, the organic phase containing 1-methylimidazole and toluene was removed, and the aqueous phase was dried under reduced pressure at 50°C for 12 hours to obtain a light red solid 6.8g. For this solid, do 1 As a result of H-NMR measurement and elemental analysis, a part of the chlorine groups in the repeating unit of the polyether polymer A (polyepichlorohydrin) as the starting material was replaced by 1-methylimidazole having a chloride ion as a counter anion. Substituted b...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| molecular weight distribution | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com