Friction ring

A technology of friction rings and friction parts, which is applied in the field of friction rings, can solve the problems of wasted cost of friction plates and achieve the effect of reducing the burden

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

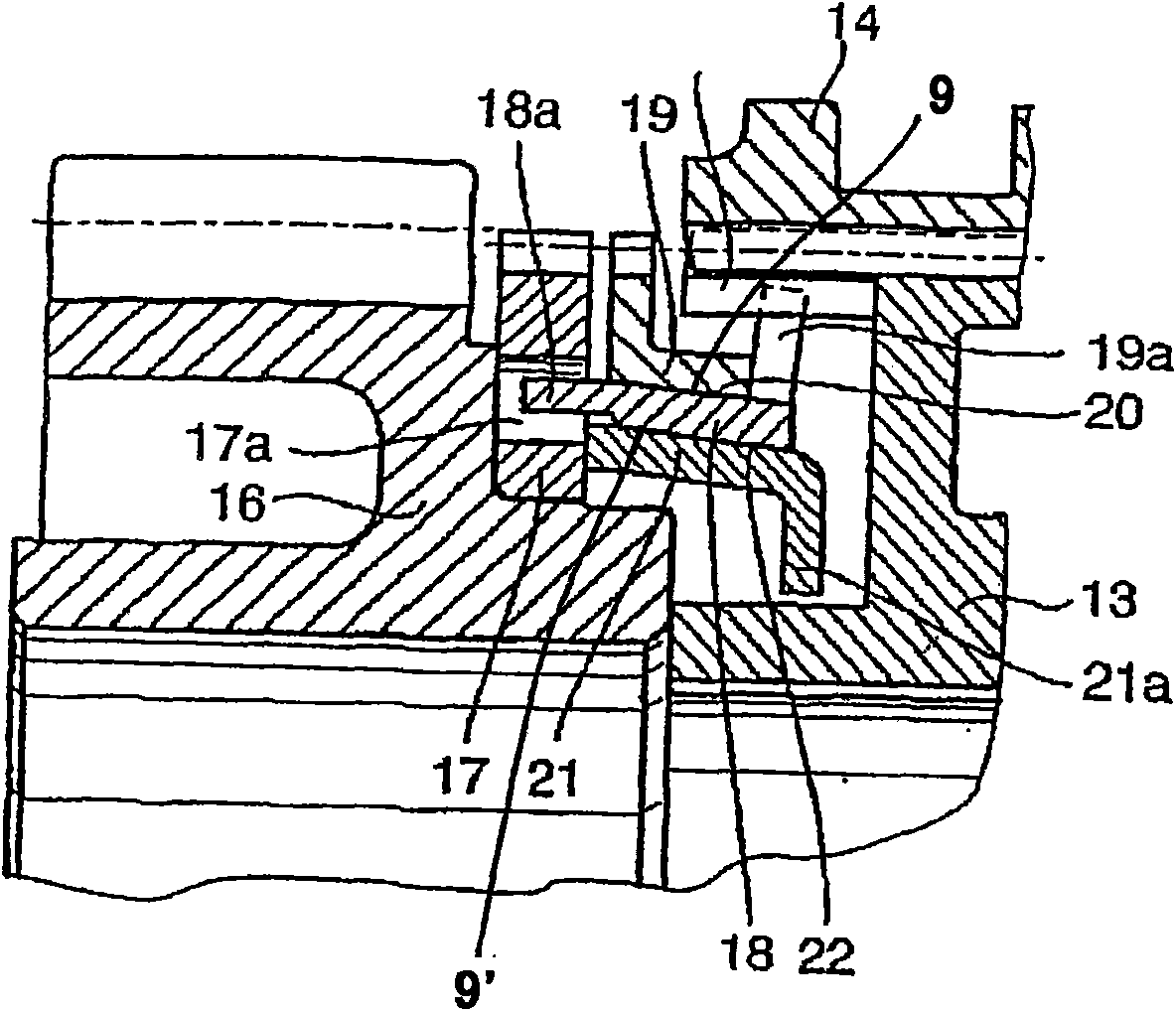

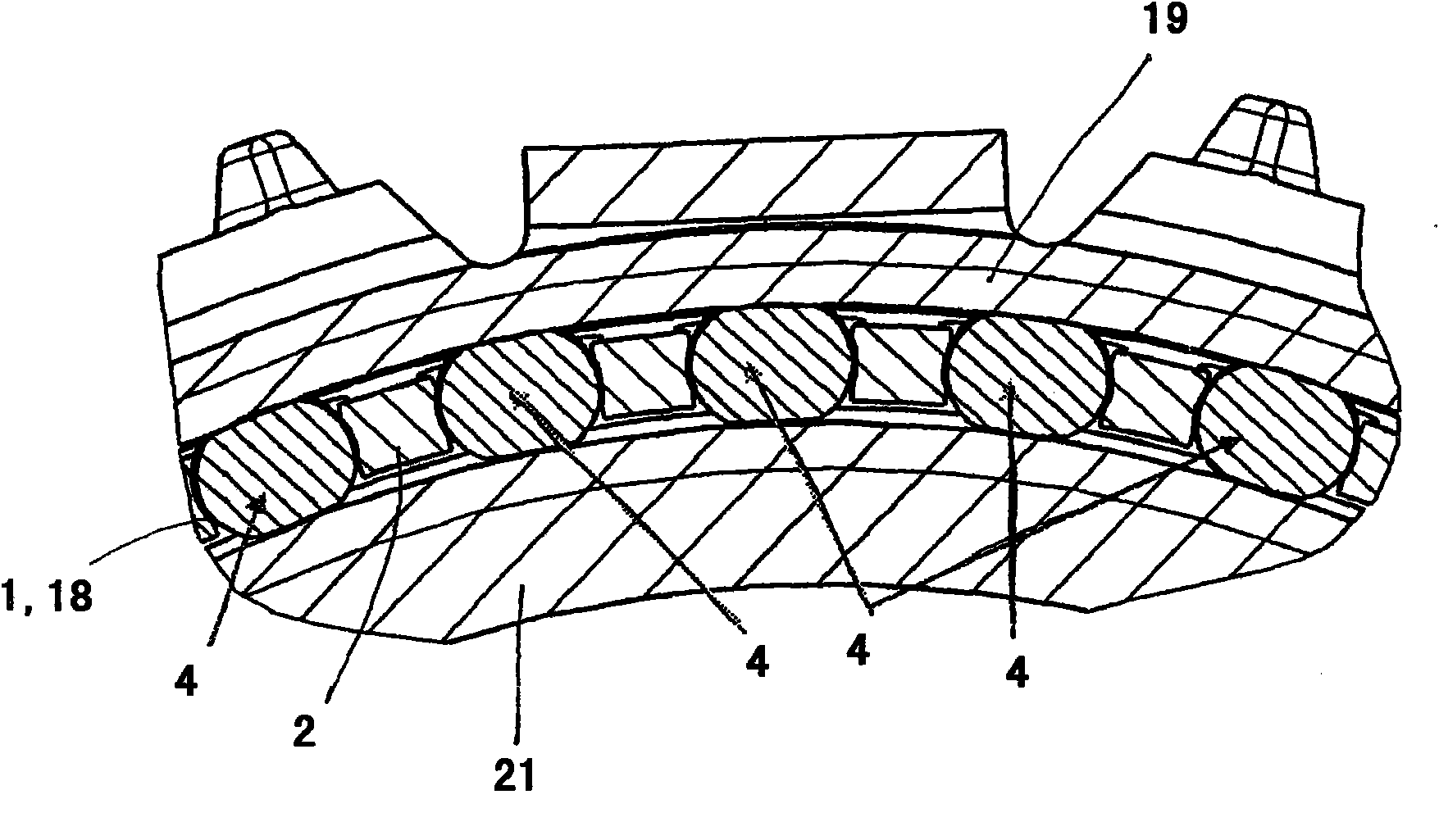

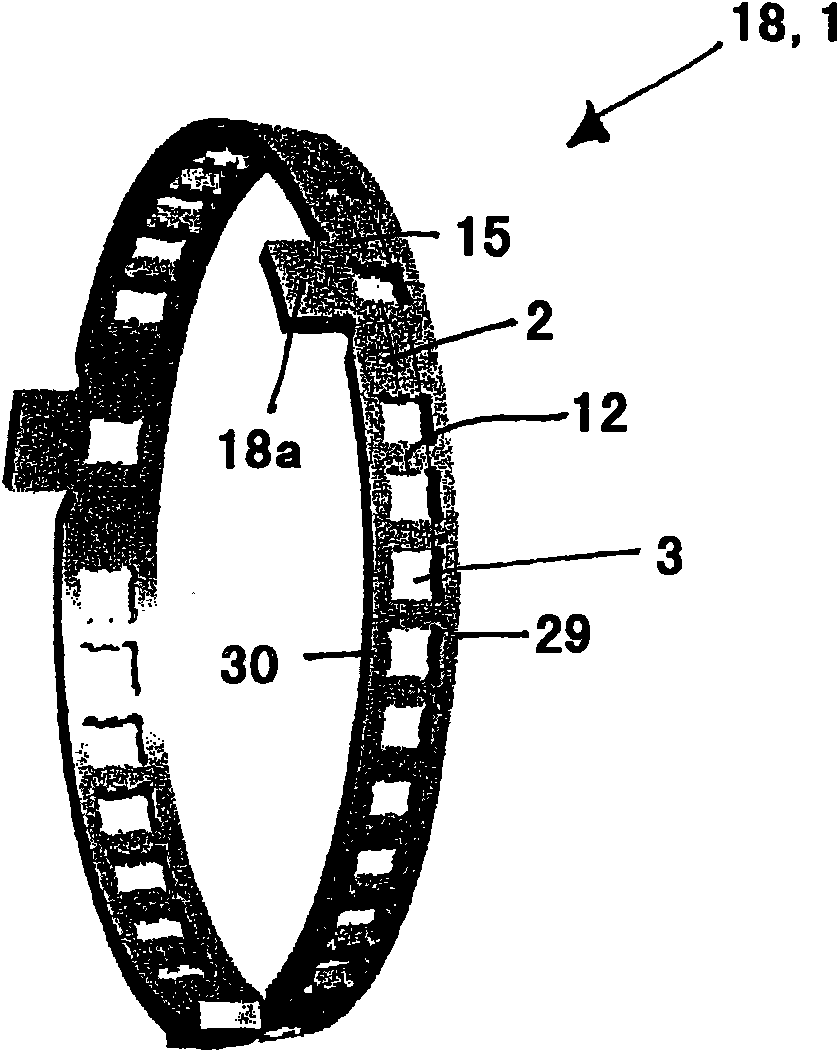

[0045] figure 1 By way of example, a synchronization device with an outer synchronizing ring 19 , a synchronizing intermediate ring 18 and an inner synchronizing ring 21 is shown. Synchronizing body 13 is secured by means of an internal toothing for a rotationally fixed arrangement on the transmission shaft. An escape wheel 16 is arranged in addition to the synchronizing body 13 . The clutch body 17 is connected to the escape wheel 16 , and the follower cam 18 a of the intermediate ring 18 engages in the recess 17 a of the clutch body 17 . The intermediate ring 18 forms a first friction pair 20 with the mating friction surface 9 of the outer synchronizing ring 19 as the mating cone 8, and forms a second friction pair 22 with the mating friction surface 9' of the inner synchronizing ring 21. The mating friction surfaces 9 and 9' are not reworked. The escape wheel 16 is connected to the synchronizing body 13 via a sliding sleeve 14 .

[0046] The inner edge 21 a of the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com