Current sensor with laminated magnetic core

A current sensor and magnetic core technology, applied in the direction of magnetic core/yoke, voltage/current isolation, transformer/inductor core, etc., can solve problems such as change, unresponsive magnetic induction, and air gap size change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

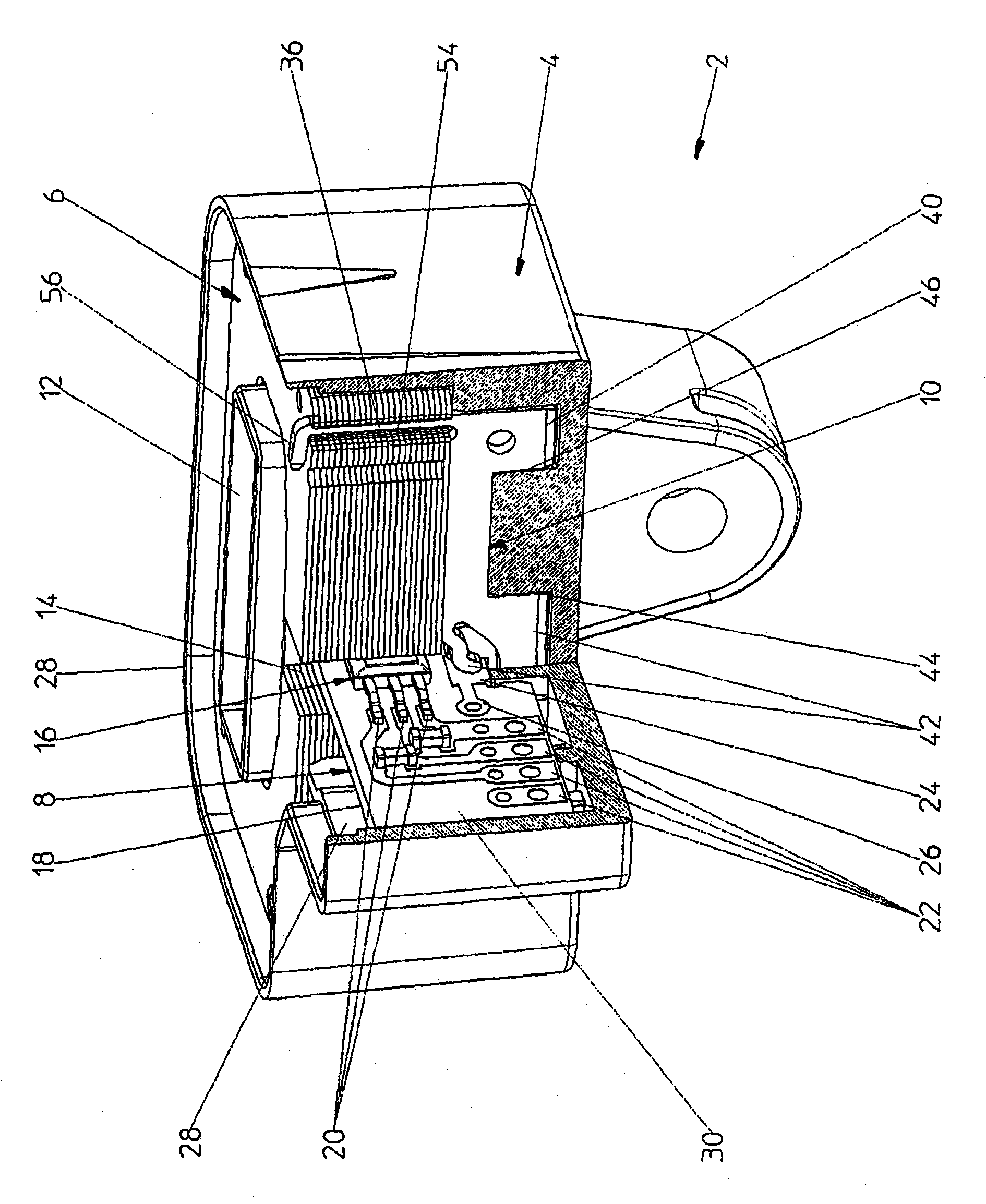

[0021] Referring to the drawings, the current sensor 2 includes a housing 4 , a magnetic core 6 , a magnetic field detector 8 and a mounting member 10 .

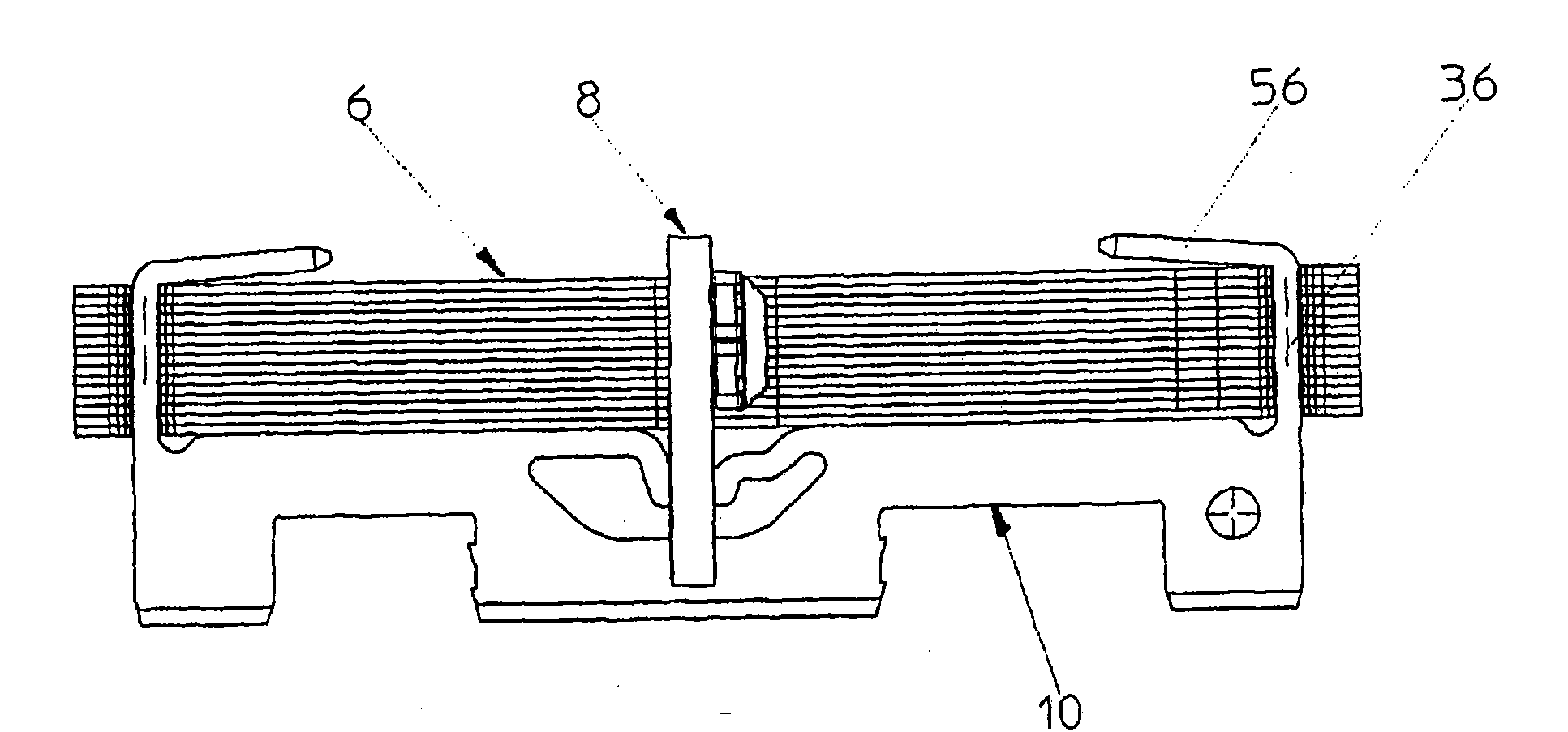

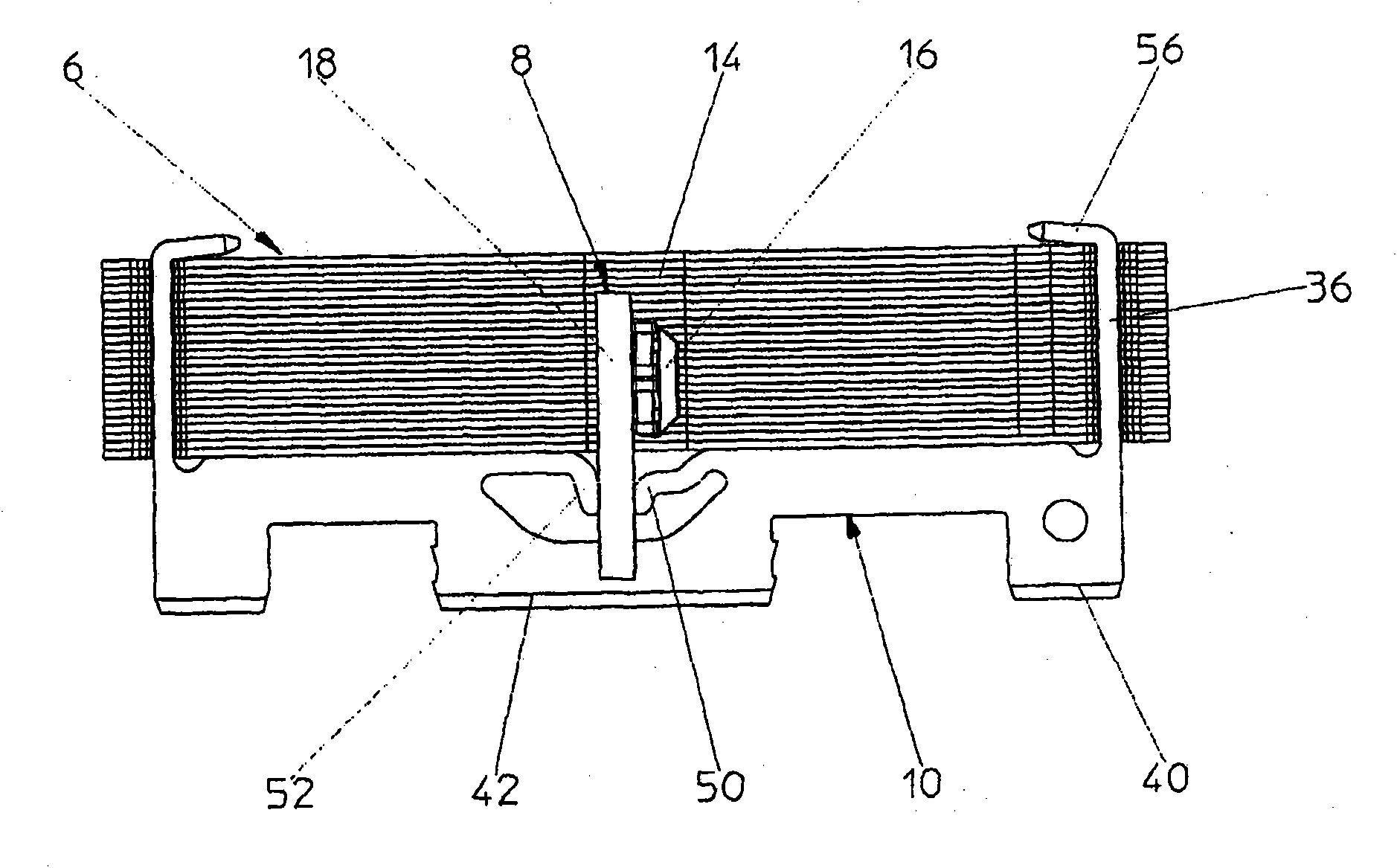

[0022] The magnetic core consists of a stack of laminar sheets of high permeability material known in the art. The magnetic core surrounds the opening 12 through which the main conductor 5 (not shown) through which the current to be measured flows passes. The magnetic core 6 has an air gap 14 which passes completely through it in the exemplary embodiment shown. However, within the scope of the invention, the air gap can also be a partial air gap, whereby the magnetic core forms a closed or substantially closed magnetic circuit. Depending on the strength of the current to be measured, the height H of the stacked sheets constituting the magnetic core can vary, as Figure 2a and 2b shown. For reasons of cost and weight it is advantageous to adjust the height of the core according to the application and the maximum specified...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com