Supporting roller device for tube type belt conveyor

A belt conveyor and idler technology, applied in the direction of rollers, conveyors, conveyor objects, etc., can solve the problems of easy damage, unevenness, and reduced service life of partitions, and achieve improved stability, prolonged contact time, and improved durability. uniform force effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

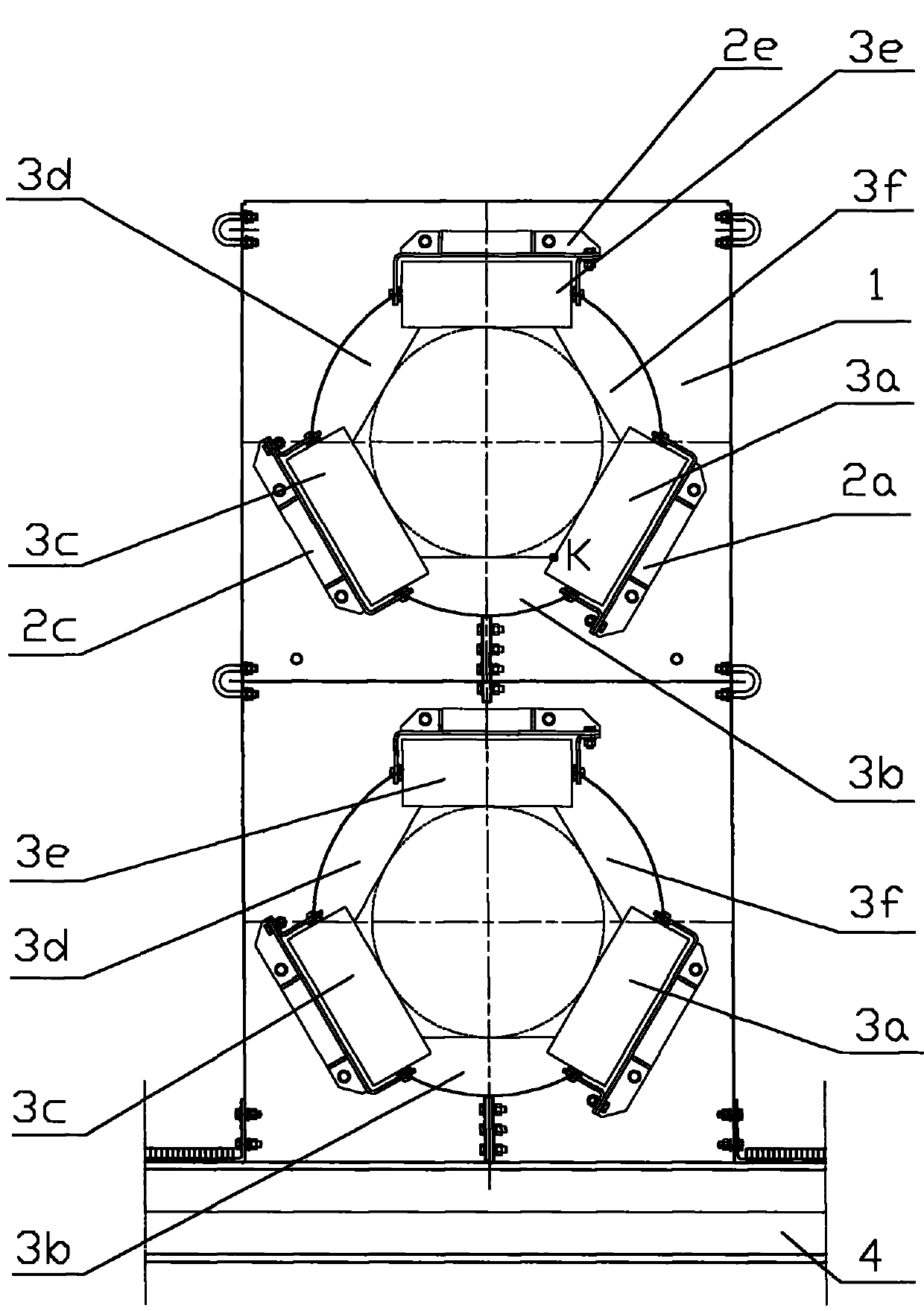

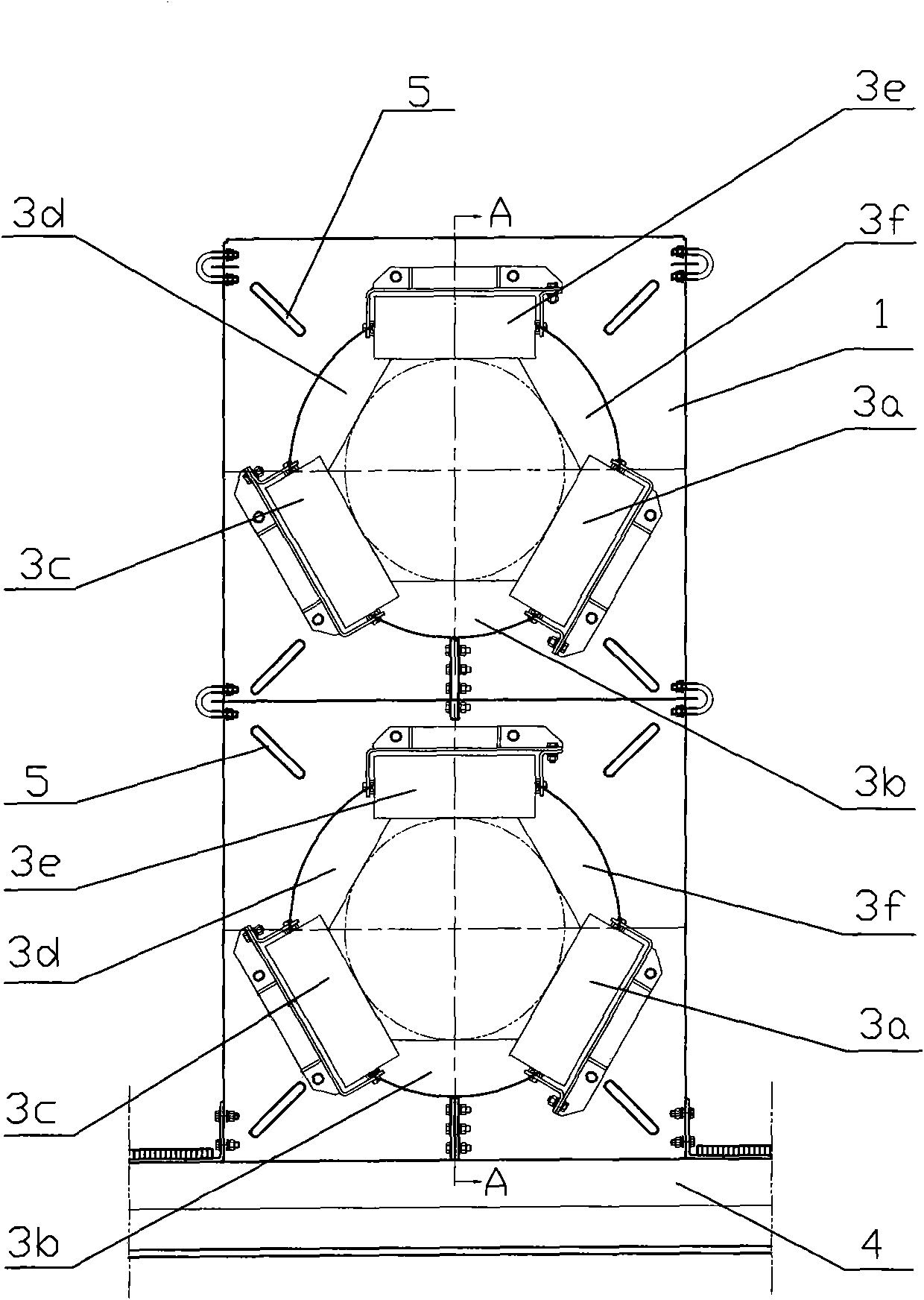

[0026] Attached figure 1 The front view of the roller device of this embodiment, attached figure 2 Is the rear view of the roller device, attached image 3 In order to omit part of the unpainted right side view of the roller frame.

[0027] As attached Figure 1~3 As shown, the supporting roller device in this embodiment is composed of a partition plate 1, a supporting roller frame 2, and a supporting roller 3. Among them, the partition 1 is fixedly installed on the frame 4 of the tubular belt conveyor, and the idler 3 is supported by the roller frame 2 and fixedly installed on the partition 1. In this embodiment, there are 6 rollers in a group, so in the figure, a, b, c, d, e, f are used to represent the 6 rollers 3 in the same group, and the corresponding roller rack 2 . Any two adjacent rollers 3, such as rollers 3a and 3b, are respectively located on both sides of the partition 1, so that both sides of the partition 1 are uniformly stressed and the rigidity is improved.

[...

Embodiment 2

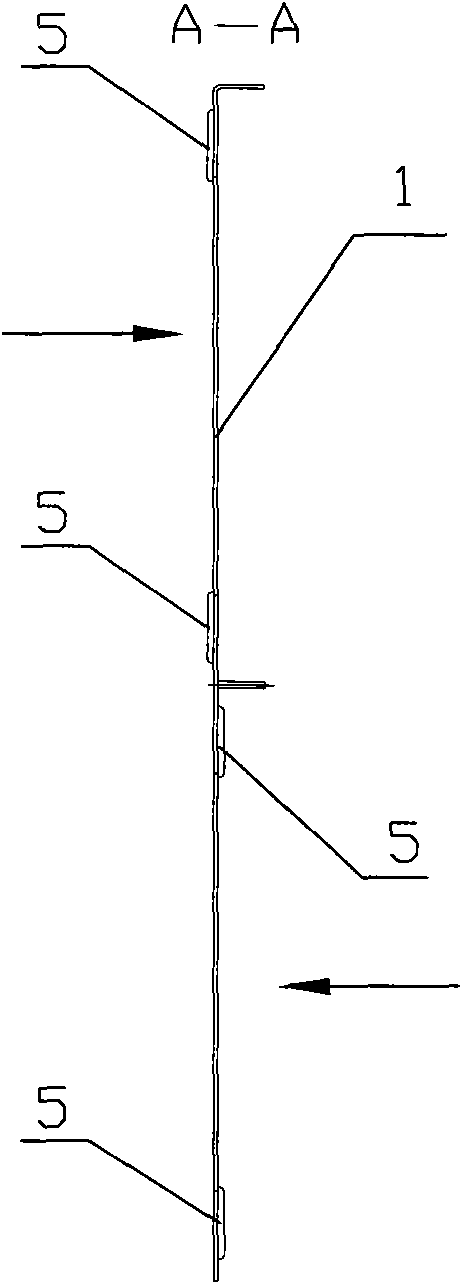

[0031] As attached Figure 4 And Figure 5 As shown, the difference between Embodiment 2 and Embodiment 1 is that four strip-shaped grooves 5 are pressed on each partition 1 to further improve the rigidity of the partition 1.

[0032] Since the adhesive tape exerts a large shear force on the partition 1 during operation, the partition 1 is likely to bend in the running direction of the tape. Therefore, a plurality of grooves 5 are pressed on the partition 1 in a direction opposite to the running direction of the tape.

[0033] These grooves 5 extend along the radial direction of the cylinder enclosed by the tape. If the partition 1 is bent due to the shearing force of the tape running for a long time, the creases are mostly around the circumference of the tape tube. Therefore, the groove 5 extending in the radial direction is perpendicular to the direction in which bending may occur, thereby resisting bending, improving the rigidity, and prolonging the service life of the separato...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com