C2 fraction selective hydrogenation method

A selective hydrogenation and fractionation technology, which is applied in the fields of hydrocarbons, chemical instruments and methods, and hydrogenation hydrocarbon production, can solve the problems of migration and aggregation of metal particles and the inability to form strong interactions, and achieve significant economic benefits and facilitate smooth operation , the effect of widening the operating range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

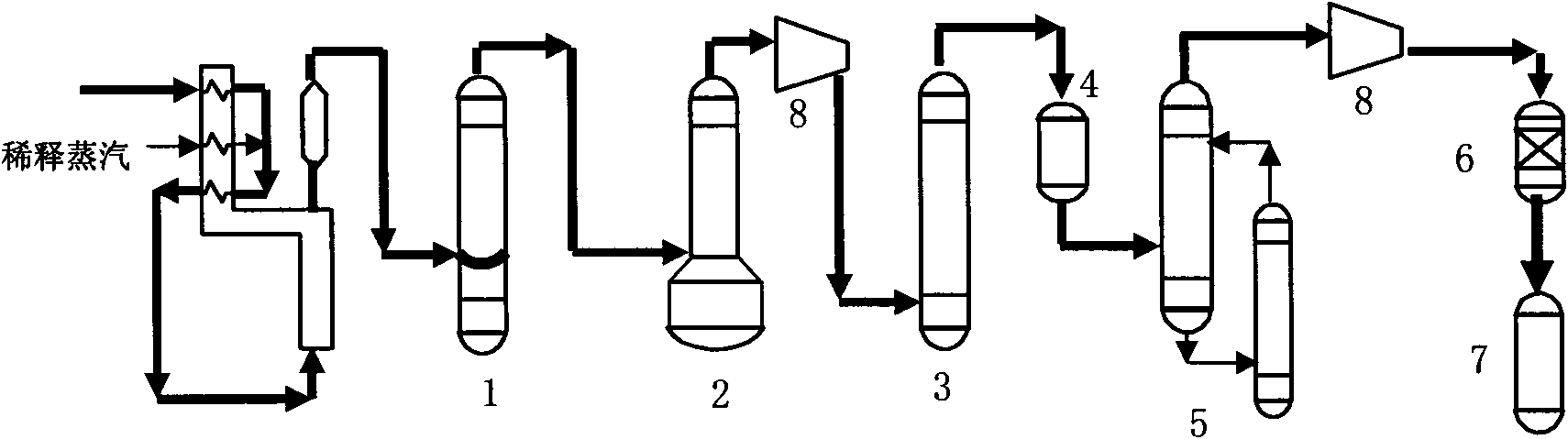

Method used

Image

Examples

Embodiment 1

[0044] The reaction material comes from the front depropanizer, and the composition of the raw material is shown in Table 1:

[0045] Table 1 hydrogenation raw material composition

[0046] Hydrogenation feedstock

H 2

C 2 h 2

C 2 h 4

C 2 h 6

CH 4

C 3 h 6

C 3 h 8

PDMA

CO

C 4 +

Content (v%)

21

0.64

34

4.36

23

14

2

0.50

0.2

0.3

[0047] Reaction process conditions: single reactor material volume space velocity: 25000h -1 ; Operating pressure: 3.9MPa; Catalyst loading capacity of each reactor: 500ml.

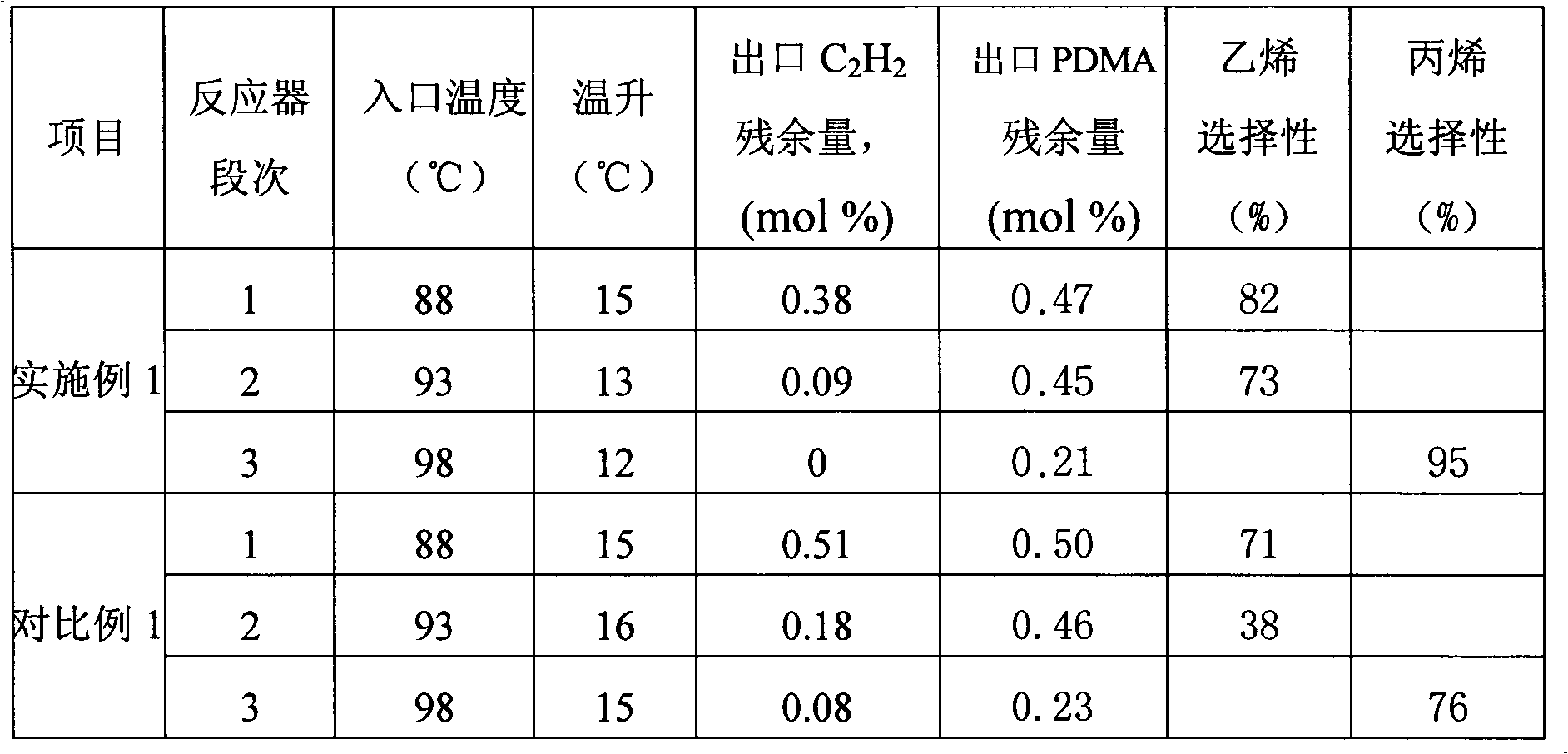

[0048] Adiabatic bed reactor, three-stage series process, and other process conditions are shown in Table 2.

[0049] The catalyst used is prepared by the method obtained in the present invention.

[0050] Weigh 500g of the carrier, the carrier is spherical Al 2 o 3 , with a specific surface area of 30m 2 / g, the pore volume is...

Embodiment 2

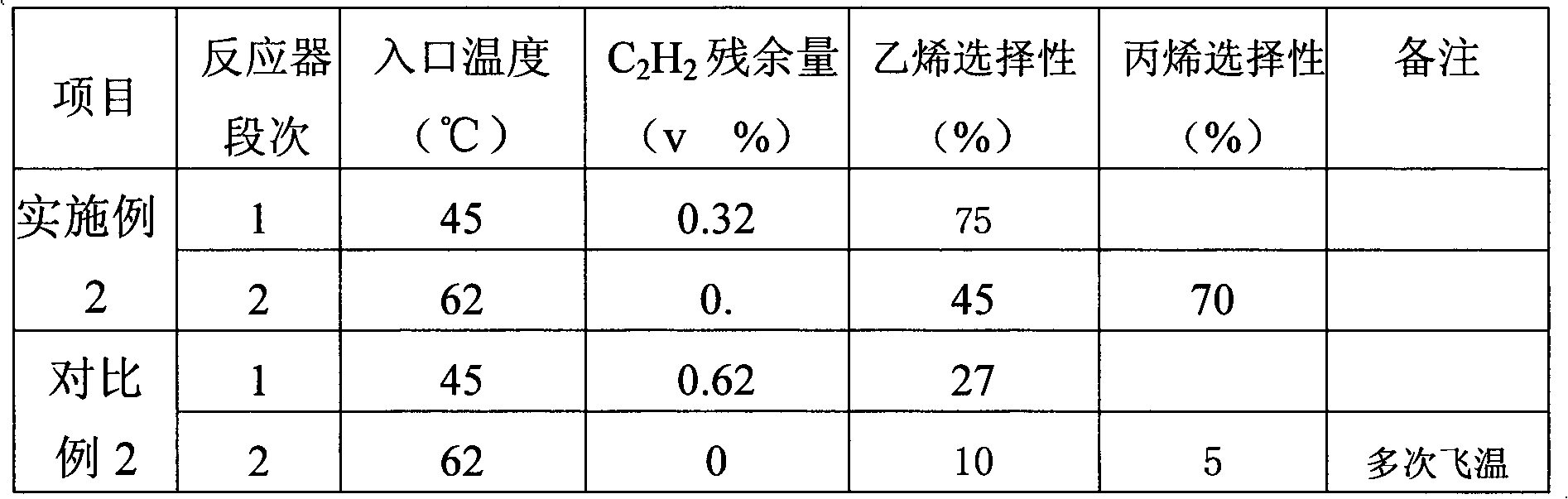

[0064] Reaction process conditions: pre-depropanization pre-hydrogenation process.

[0065] Material air speed: 10000h -1 , Operating pressure: 3.5MPa, single-stage adiabatic bed reactor, catalyst loading: 800ml.

[0066] The hydrogenation reaction material comes from the top of the front depropanizer, and its composition is shown in Table 3.

[0067] Table 3 hydrogenation raw material composition

[0068] Hydrogenation feedstock

H 2

C 2 h 2

C 2 h 4

C 2 h 6

CH 4

CO

C 3 h 6

C 3 h 8

PDMA

Content (V%)

20

1.0

40.68

6..8

17

0.02

12

2

0.50

[0069] Catalyst preparation:

[0070] Weighing length is 4.5mm, specific surface area is 2m 2 / g, the pore volume is 0.20ml / g, the bulk density is 1.2g / cm 3 Cylindrical Al2 o 3 Carrier 500g.

[0071] Weigh 0.60g Pd(NO 3 ) 2 2H 2 O, 5.27g Mg(NO 3 ) 2 ·6H 2 O, 4.8g g urea, is dissolved in deionized w...

Embodiment 3

[0085] Reaction process conditions: pre-depropanization and pre-hydrogenation process, two-stage adiabatic reactor; single-stage or each-stage material volume space velocity: 3000h -1 ;Operating pressure: 4.5MPa, each catalyst filling volume: 300ml.

[0086] The raw material for hydrogenation also comes from the front depropanizer, and its composition is shown in Table 5.

[0087] Table 5 hydrogenation raw material composition

[0088] Hydrogenation feedstock

H 2

C 2 h 2

C 2 h 4

C 2 h 6

CH 4

C 3 h 6

C 3 h 8

PDMA

CO

C 4 +

Content (v%)

15

0.4

32

4.28

30

15

2.3

0.7

0.02

0.3

[0089] Weigh spherical Al 2 o 3 Carrier 500g, its specific surface area is 10.3m 2 / g, the pore volume is 0.40ml / g, the bulk density is 1.1g / cm 3 .

[0090] Weigh 0.47g Pd(NO 3 ) 2 2H 2 O, 23g Mg(NO 3 ) 2 ·6H 2 O, 3.1g of urea is prepared into a mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com