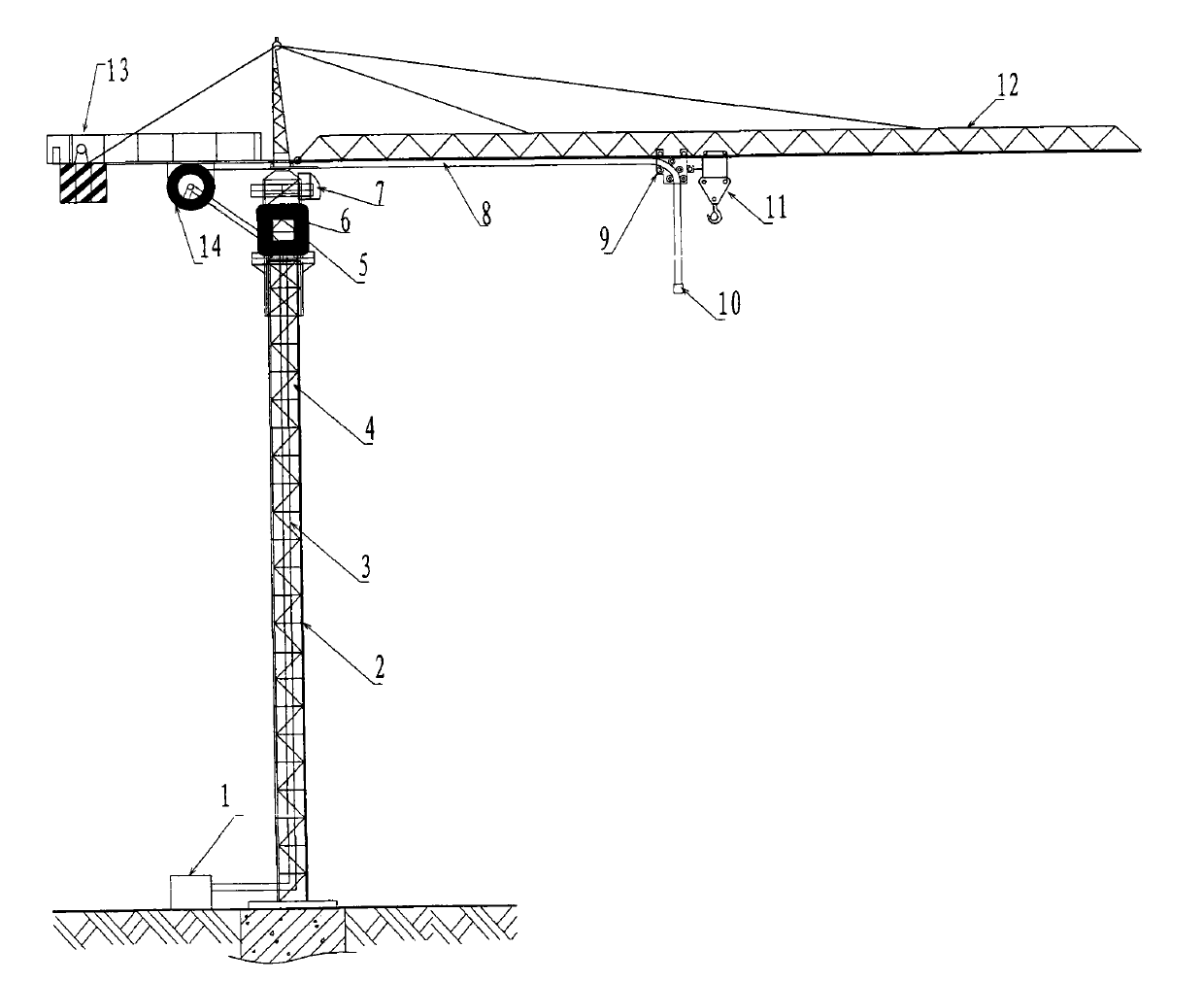

Material-distributing mechanism fixed on tower crane

A tower crane and cloth technology, which is applied in building construction, building material processing, construction, etc., can solve the problems of limited watering height and high cost, and achieve the effect of fast watering, reducing labor intensity and saving costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

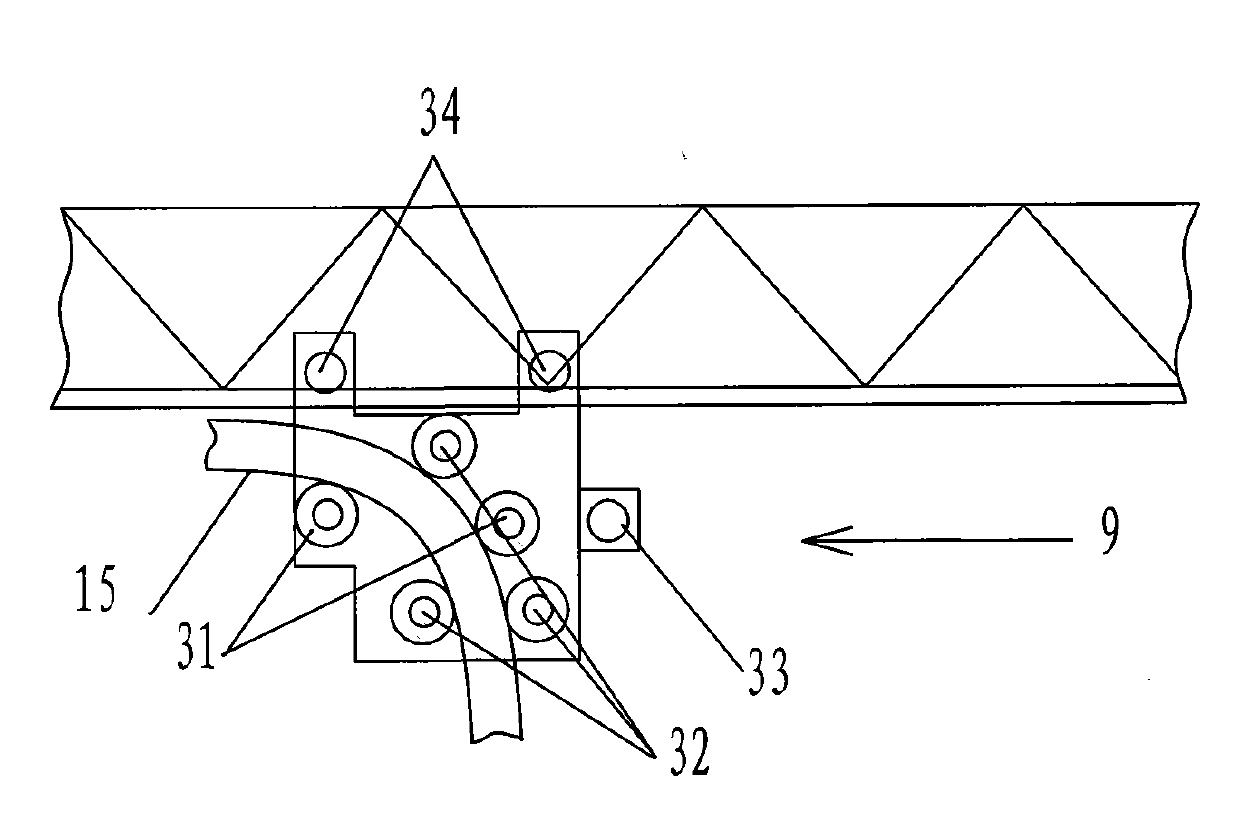

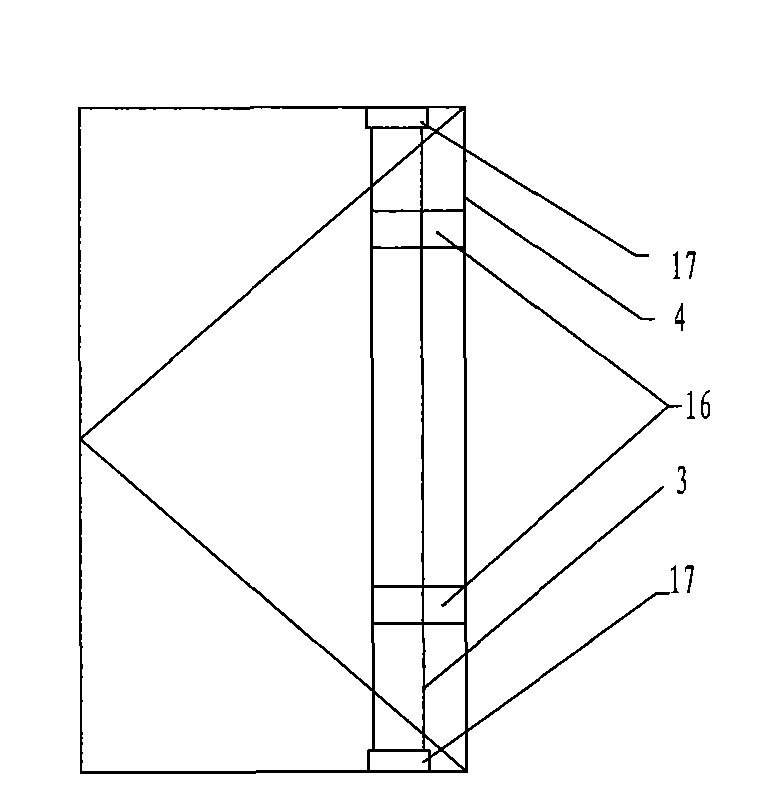

[0018] See Figure 1-3 , the concrete structure of the present invention is as follows: the unit cement slurry conveying steel pipe 3 that length is consistent with 2 heights of tower body standard section is fixed on tower body standard section main beam 4 with clamp 16 (being the fixed connector that generally uses), and a plurality of The unit cement slurry delivery steel pipe 3 is connected up and down by the flange 17. Corrugated metal tubes with a certain amount of expansion and contraction can be arranged at intervals (see image 3 ), the delivery steel pipe 3 is connected with the corrugated metal pipe with the flange 17. See Figure 4 , the upper and lower rotation 5 of the tower body is provided with an upper rotation 18 and a lower rotation 19, a slewing support 20 is set between the upper rotation 18 and the lower rotation 19, the conveying steel pipe 3 passes through the upper and lower rotation 5, and the conveying steel pipe 3 is provided with a rotary joint o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com