Hydraulic expansion-type rotary liner hanger

A liner hanger and expansion technology, which is applied in wellbore/well components, earthwork drilling, sealing/isolation, etc., can solve the problems of inconvenient assembly of feeding joints, unguaranteed cementing quality, and poor sealing performance. Unreliable and other problems, to achieve the effect of improving displacement efficiency, avoiding mud dead zone, and improving cementing success rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described now in conjunction with the accompanying drawings of the description.

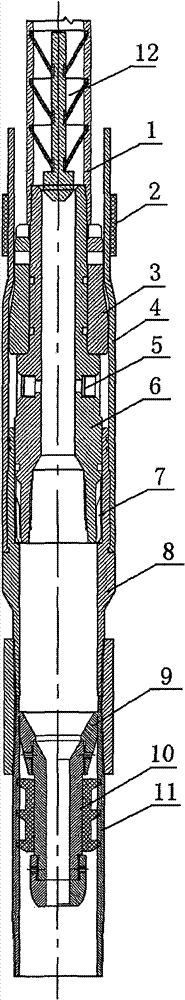

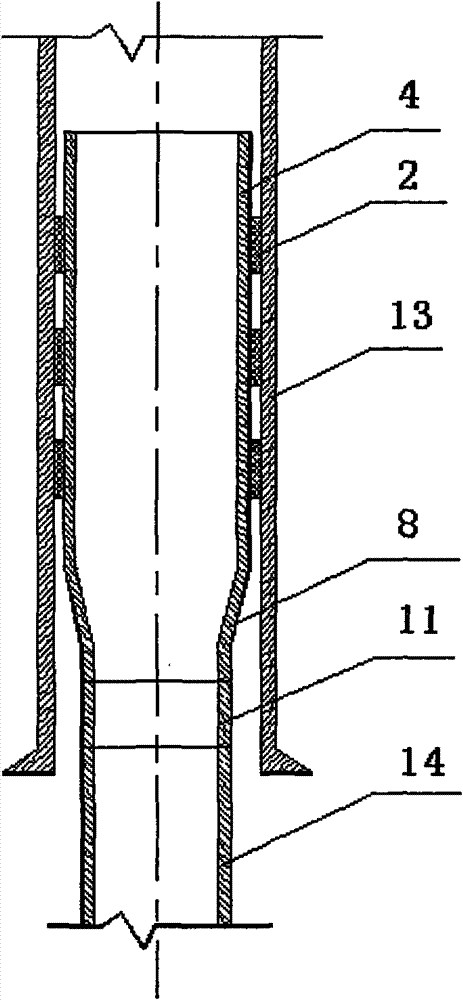

[0018] as attached figure 1 , attached figure 2 As shown, the hydraulic expansion rotary liner hanger is mainly composed of a center tube 1, a rubber ring 2, an expansion cone 3, a hanger body 4, a spline shaft 6, a double male joint 8, a rubber plug shear seat 9, and a hollow rubber Plug 10, cementing plug 12 and plug conduit 11. The hanger body 4 is a section of expansion tube with reduced diameter, a rubber ring 2 is added to the small diameter end, the lower end of the body is connected with the double male joint 8, and the double male joint [8] is internally processed with a spline groove, and the spline groove and the spline shaft 6 The spline 7 on the coupling is fixed. The upper end of the spline shaft 6 is connected with the central pipe 1, and a burst disc 5 is installed in a pair of through holes in the circumferential direction of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com