Armature coil of rotating electric machine

A technology for armature windings and rotating electrical machines, applied in the shape/pattern/structure of winding conductors, and the shape/pattern/structure of winding insulation, etc., can solve problems such as unbalanced electromagnetic force, increase terminal voltage, transmission or setting restrictions, etc. , to achieve the effects of suppressing corona discharge, improving reliability, and reducing potential difference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

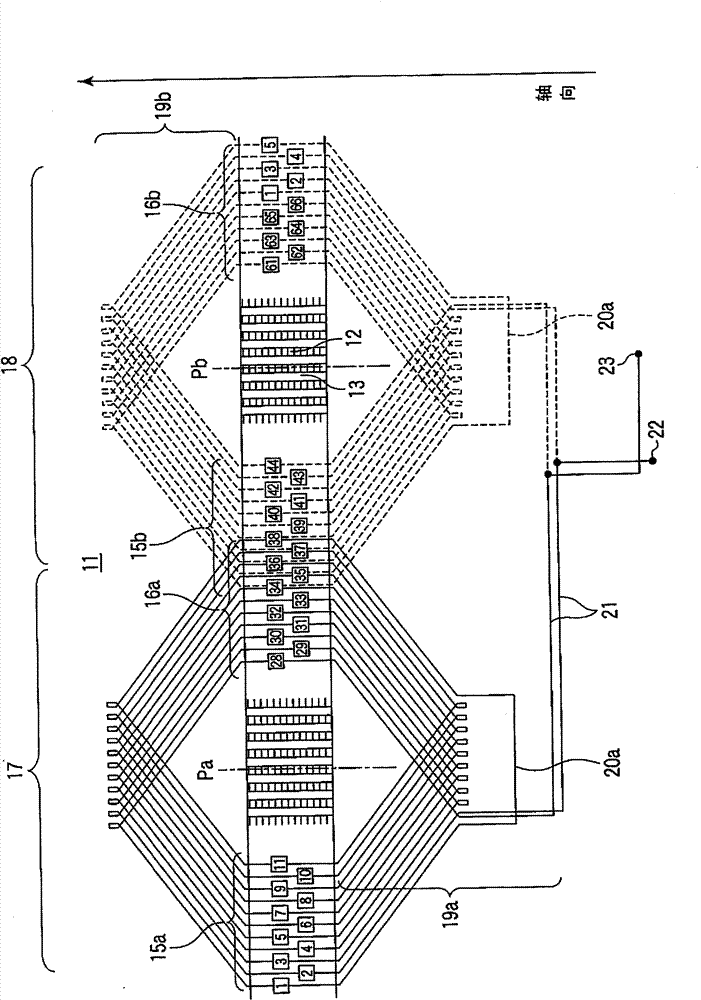

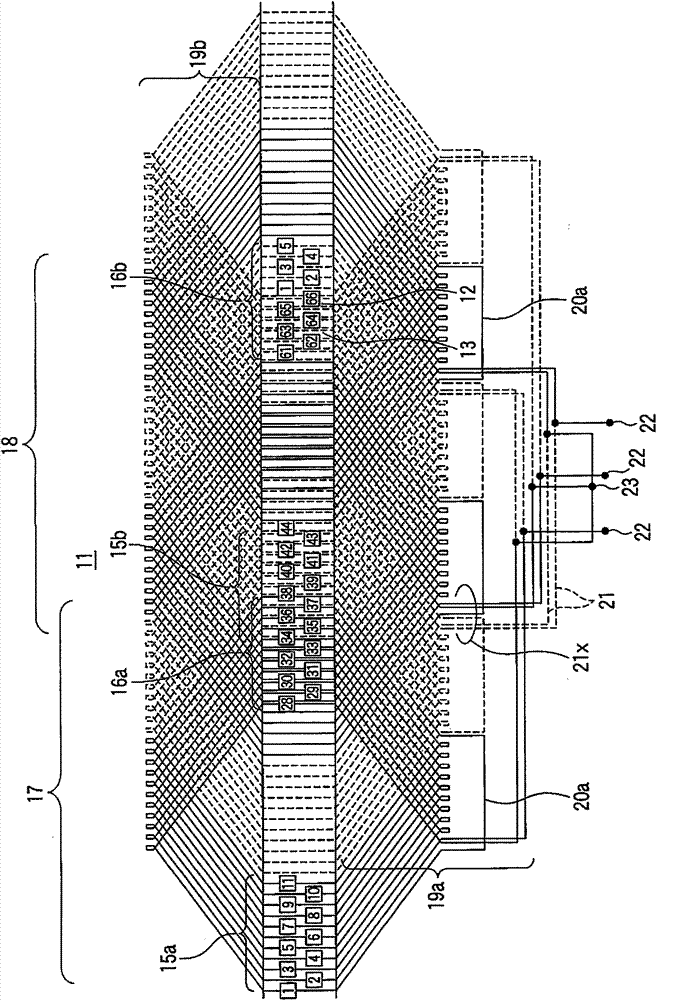

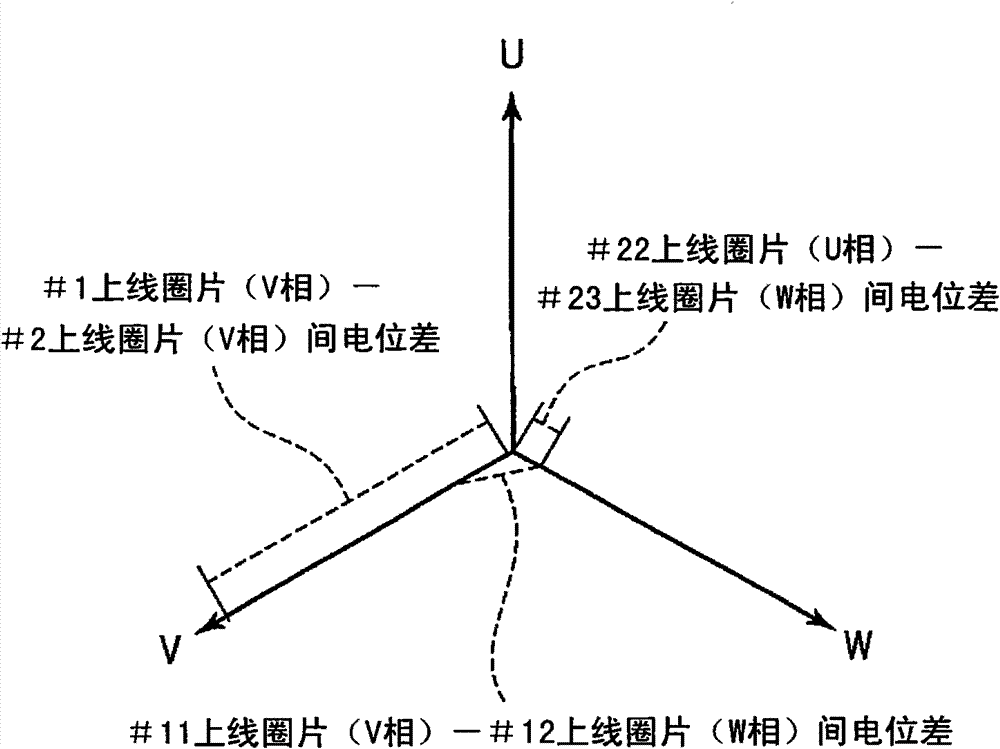

[0116] figure 1 It is an expanded schematic view showing a phase portion of the first embodiment of the armature winding of the rotating electric machine according to the present invention, figure 2 is an expanded pattern diagram of the 3-phase part of the same embodiment, for figure 1 The structure of the armature winding of the 1-phase portion shown is shown by adding 2 phases arranged so that the electrical angles are shifted by 120 degrees and 240 degrees, respectively.

[0117] Such as figure 1 As shown, the armature 11 of the rotating electrical machine is provided with 66 slots 13 on the armature core 12 composed of laminated iron cores, and the armature windings 14 of the 2-pole, 3-phase, 2-parallel circuit are accommodated in two layers in these slots. . The armature winding 14 of each phase has: an upper coil piece 15 (15a, 15b) accommodated in the opening side of the slot; a lower coil piece 16 (16a, 16b) accommodated in the bottom side of the slot; The ends...

no. 2 Embodiment approach

[0166] Figure 9 It is a developed schematic diagram showing the phase 1 of the second embodiment of the armature winding of the rotating electric machine according to the present invention, and the remaining two phases are constructed by shifting the electrical angles by 120 degrees and 240 degrees. related to and figure 1 The same structure, its description is omitted.

[0167] Such as Figure 9 As shown, the armature 11 of the rotating electric machine is provided with 66 slots 13 on the armature core 12 composed of laminated iron cores, and in these slots 13, the armature windings 14 of the 2-pole, 3-phase, 2-parallel circuit are accommodated in 2 layer.

[0168] In the present embodiment, the coil pitch of the coil end portion 19a on the connection side is 28, which is 1 larger than the winding pitch, and the coil pitch of the coil end portion 19b on the counter-connection side is 27, which is equal to the winding pitch.

[0169] In the second embodiment, if Figure...

no. 3 Embodiment approach

[0177] Figure 10 It is an expanded schematic view showing a 1-phase portion of a third embodiment of an armature winding of a rotating electrical machine according to the present invention, which is a 2-pole, 3-phase, 2-parallel circuit and has 66 slots in the armature core. For the remaining two phases, they are configured by shifting the electrical angle by 120 degrees and 240 degrees. related to and figure 1 The same structure, its description is omitted.

[0178] In the drawing, on the connection side, the first upper coil piece and the 28th lower coil piece are connected, and the coil pitch is 27, which is equal to the winding pitch. On the other hand, on the reverse connection side, the second upper coil piece and the 28th lower coil piece are connected, and the coil pitch is 26, which is one less than the winding pitch.

[0179] In this embodiment, if Figure 10 As shown, on the connection side coil end portion 19a of the first phase belt 17, the lead-out connecti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com