Method for optimizing structure of finished cut tobacco

A shredded tobacco structure and shredded tobacco technology, applied in the field of tobacco, can solve problems such as not optimizing the shredded tobacco structure, achieve the effect of reducing the coefficient of variation of quality and improving the uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

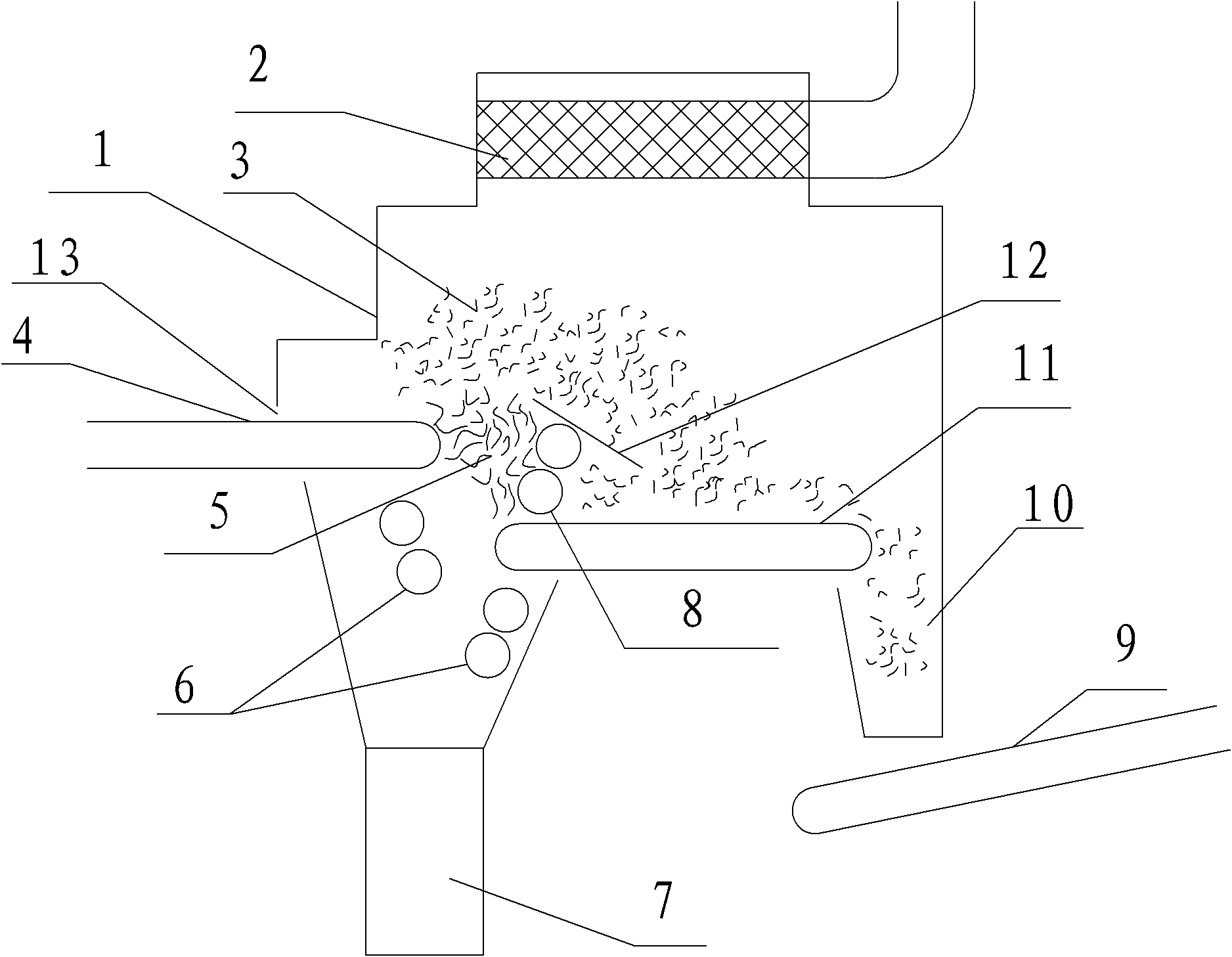

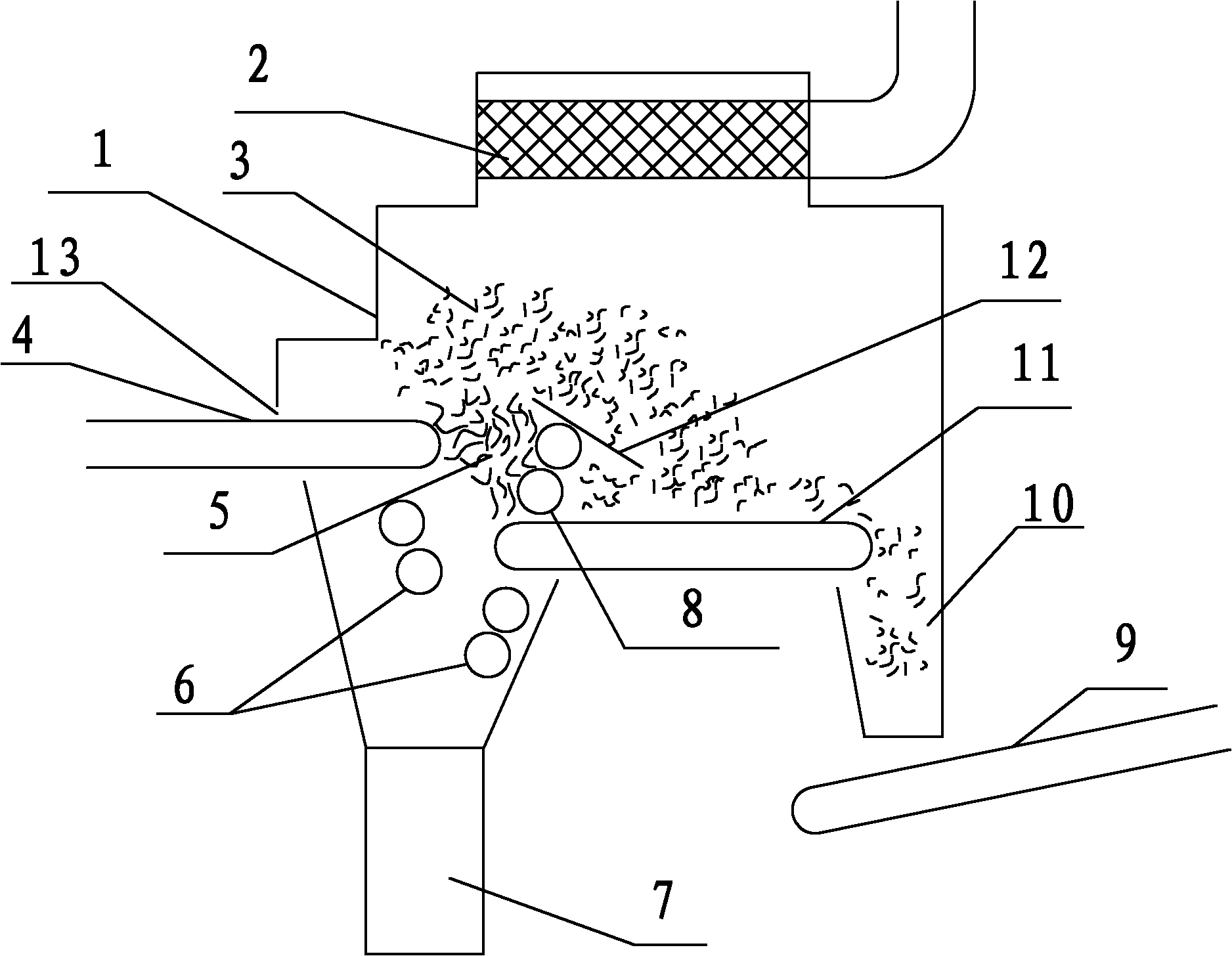

[0021] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0022] Such as figure 1 As shown, a method for optimizing the structure of finished tobacco shreds comprises the following steps:

[0023] 1). Feeding, the shredded tobacco is thrown and suspended into the winnowing device 1;

[0024] 2). Selection of shredded tobacco, selecting long shredded tobacco 5>3.35mm;

[0025] 3). Introduce the broken wire channel, and guide the long shredded tobacco 5>3.35mm into the broken wire channel;

[0026] 4). Slitting and cutting the long shredded tobacco, cutting the agglomerated and braided long shredded tobacco 5 in the broken wire passage;

[0027] 5). Mix evenly, transport the qualified shredded tobacco and the remaining qualified shredded tobacco to the next process in step 4), and mix the aforementioned two evenly;

[0028] 6). Return, the cut unqualified agglomerated shredded tobacco in step 4) falls on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com