Floating raft type oil-water separator and method for separating volatile oil and water

An oil-water separator and volatile oil technology, which are applied in separation methods, chemical instruments and methods, liquid separation and other directions, can solve the problems of decreased volatile oil purity, mixed impurities, inconvenient operation, etc., to achieve simple separation operation, good separation effect, The loss of small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

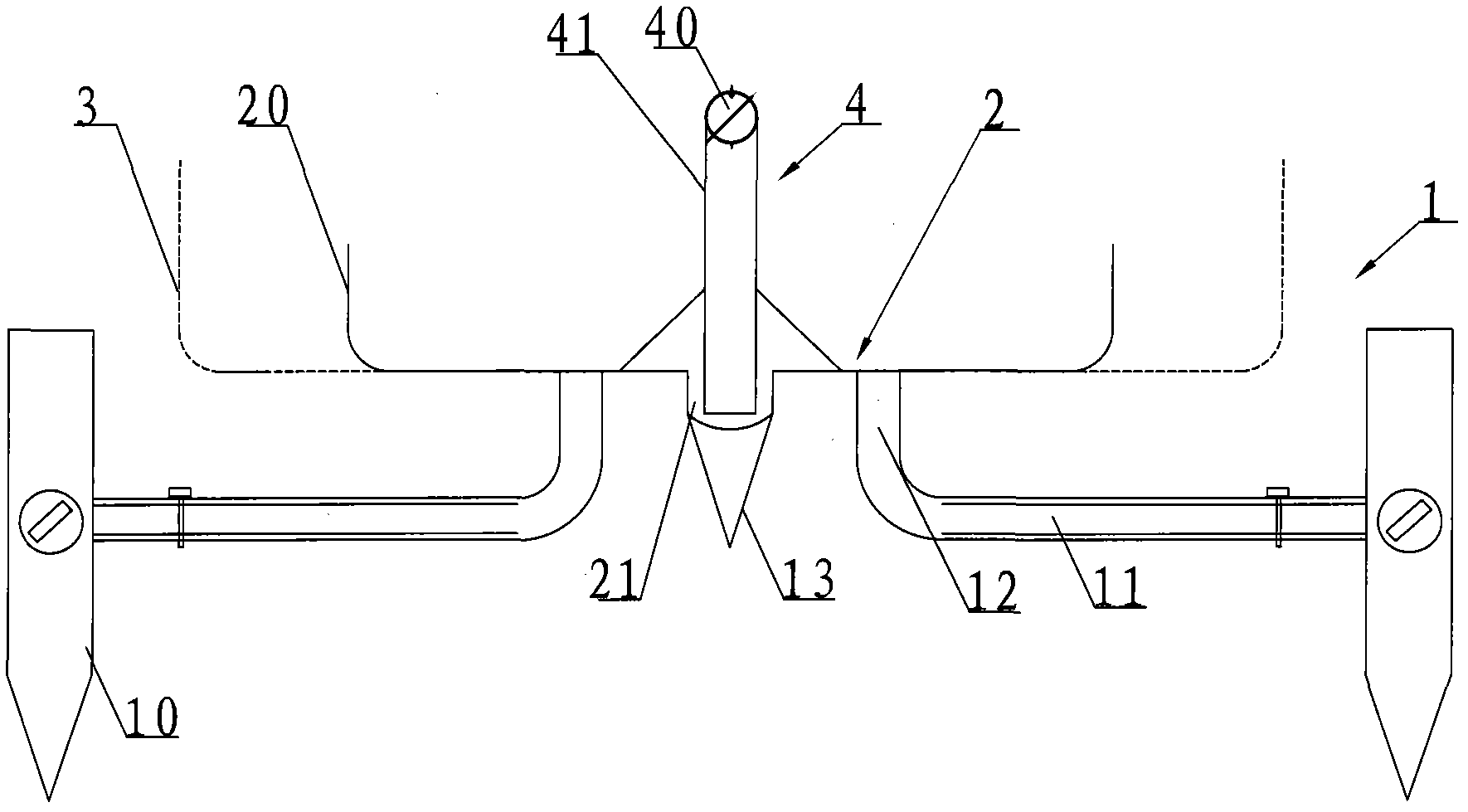

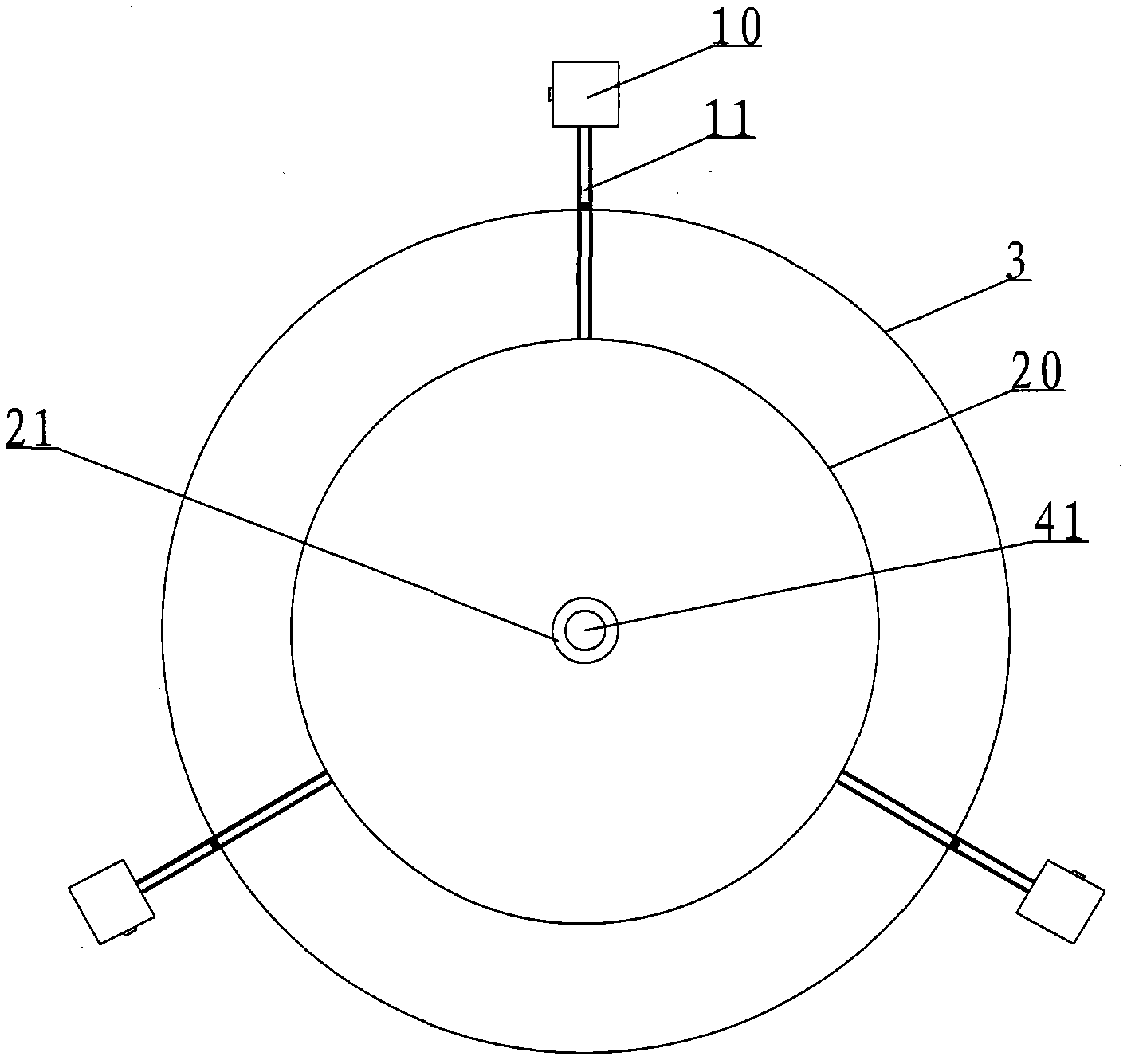

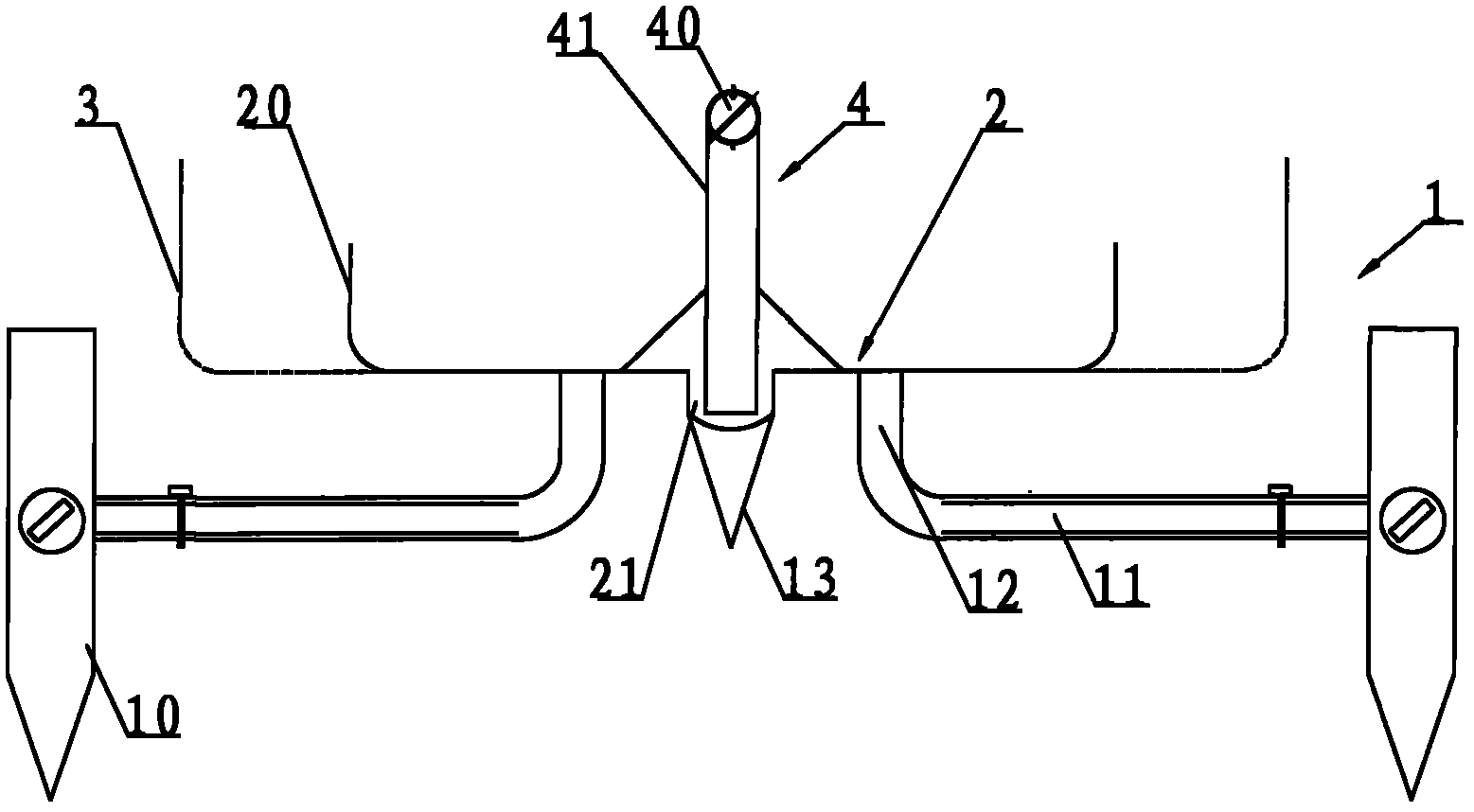

[0026] This embodiment provides an oil-water separator. Such as figure 1 and 2 As shown, the oil-water separator includes a base 1 , a collector 2 fixedly supported by the base 1 , a filter screen 3 surrounding the periphery of the collector 2 , and an extraction device 4 for extracting liquid in the collector 2 .

[0027] The collector 2 has a collector body 20 in the shape of a barrel and a central groove 21 formed by a downward depression at the center of the collector body 20. When separating, oil with a lower density flows from the upper end of the side wall of the collector body 20. The edge overflows in and finally flows into the central groove 21 . The bottom surface of the central groove 21 is arc-shaped. The lower end of the oil outlet pipe 41 of the extraction device 4 is correspondingly inserted into the central groove 21, and under the action of the oil pump 40, the oil in the central groove 21 is drawn away. The filter screen 3 is set on the outer periphery o...

Embodiment 2

[0031] A method for separating peppercorn essential oil from a mixture of peppercorn essential oil extracted by steam distillation and water, the specific process is as follows: after the mixture is layered, insert the oil-water separator of Example 1 into it, and adjust the connecting rod 11 The height makes the upper end of the side wall of the collector body 20 be in the position between the liquid level of the mixed liquid and the interface, so that after the prickly ash essential oil on the upper layer is filtered out solid suspended matter through the filter screen 3, it will flow from the side wall of the collector body 20 The upper end overflows into the collector body 20, and finally the oil well pump 40 is drawn away from the collector body 20 to realize oil-water separation. After testing, the purity of the pepper essential oil can reach more than 90%, does not contain solid suspended impurities, and the loss rate of the pepper essential oil is less than 1%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com