Multi-parameter compound environmental tester

An environmental test device and multi-parameter technology, applied in measuring devices, simulators of space navigation conditions, transportation and packaging, etc., can solve problems such as low precision, poor test effect, and inability to fully simulate the working environment of devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

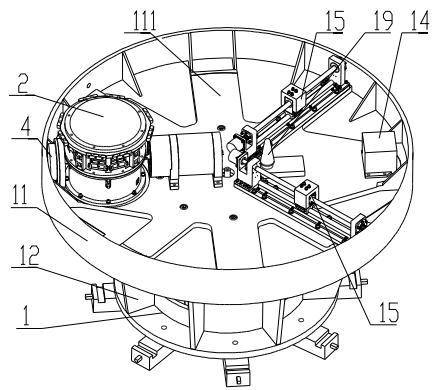

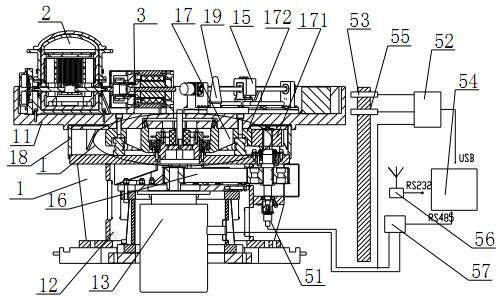

[0112] refer to figure 1 , 2 , 3, 16, 18, 19, 20, 21, 22

[0113] A multi-parameter composite environmental test device, including a centrifuge 1 for simulating environmental linear acceleration and an environmental chamber 2 installed on the arm 11 of the centrifuge 1 to simulate vibration acceleration, environmental noise, ambient temperature and air pressure in the environment;

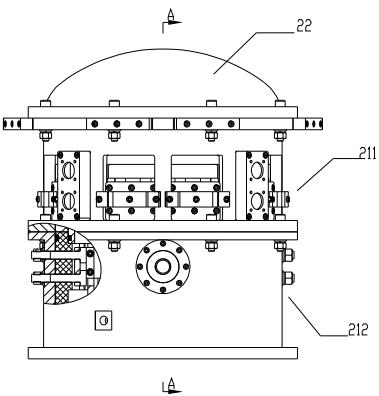

[0114] Described environmental cabin 2 comprises airtight box body, and described box body is connected with a box cover 22 sealingly, and described box body and box cover 22 all comprise to be made by metal, to guarantee the outer layer of box body rigidity and An insulation layer made of non-metal to maintain the internal temperature of the composite cavity, the inner cavity of the box body forms an environmental composite cavity independent of the outside world;

[0115] The interior of the compound chamber is provided with from top to bottom in turn: the noise generating mechanism 23 fixed on...

Embodiment 2

[0136] refer to Figure 19

[0137] The difference between this embodiment and Embodiment 1 is that the deviation correction mechanism 4 includes: a partition 41 affixed to the deviation correction push rod, and airtight hyperbaric chambers located on both sides of the partition 41 42, and the low pressure chamber 43 that communicates with the atmosphere, the displacement sensor 44 that is positioned at the hyperbaric chamber 42 and facing the partition 41 to monitor the displacement of the deviation correction push rod 243, and supports the hyperbaric chamber 42 and The support of the low pressure cabin 43; the support is fixed on the web 111 of the machine arm 11, and the output signal of the displacement sensor 44 is input into a controller;

[0138] The hyperbaric chamber 42 is provided with an air inlet connected to the high-pressure air pump through an inflation solenoid valve, and an air outlet connected to the atmosphere through a deflation solenoid valve, and the inf...

Embodiment 3

[0148] refer to Figure 11-1~15

[0149] The difference between the present embodiment and the second embodiment is that the centrifuge 1 includes a base 12, a drive motor 13 fixed on the base 12, a machine arm 11 carrying a composite parameter test device, and the The power of the drive motor 13 is transmitted to the transmission mechanism of the machine arm 11, the static balance mass 14 fixed on the machine arm and the dynamic balance installed on the machine arm 11 to realize adaptive dynamic balance executive body;

[0150] The arm 11 is disc-shaped, the arm 11 is evenly provided with a web 111, and the environmental chamber 2 is installed on the web 111;

[0151] Described transmission mechanism comprises the belt transmission mechanism 16 that is connected with the output shaft of described drive motor and the gear mechanism 17 that is connected with described machine arm 11; The pinion gear 171 and the bull gear 172 affixed to the machine arm 11;

[0152] The upper...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com