Spherical catalyst for 1-butene polymerization as well as preparation method and application thereof

A technology for butene polymerization and catalyst is applied in the field of spherical catalyst and its preparation, and achieves the effects of improving processability, saving cost and improving performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

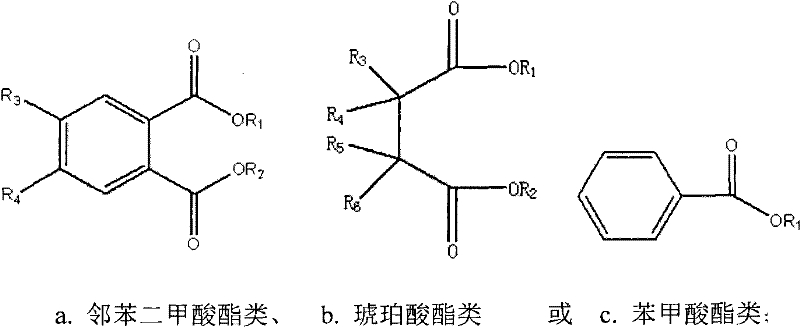

Method used

Image

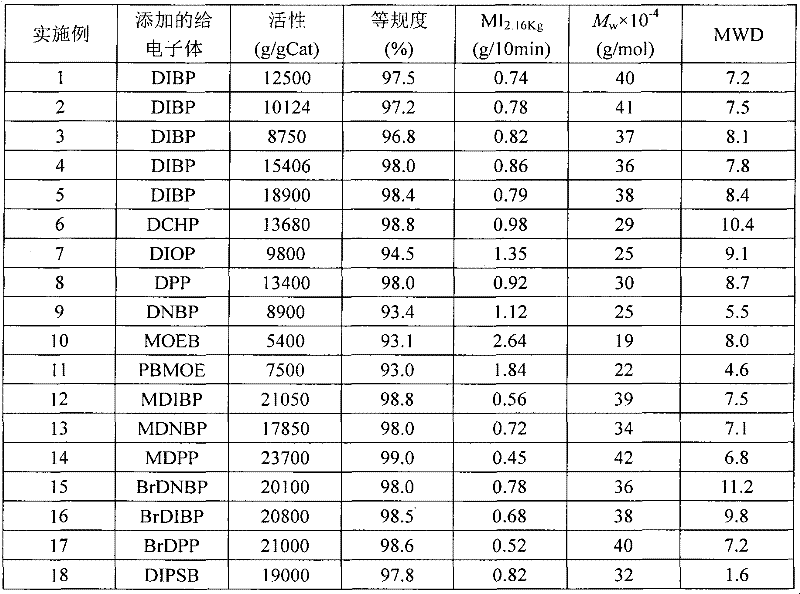

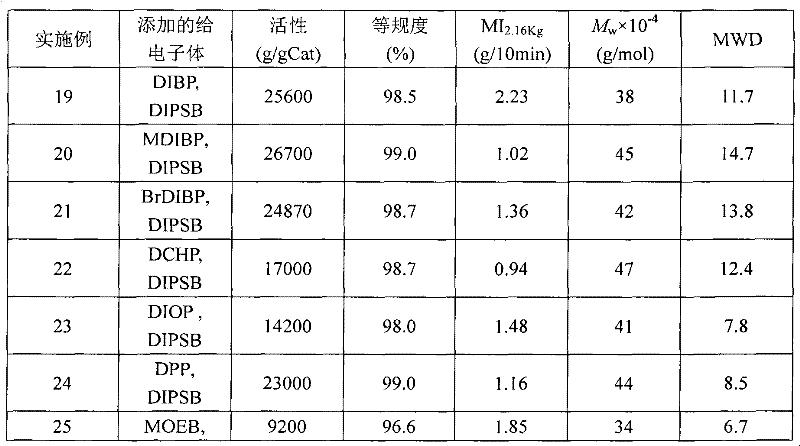

Examples

Embodiment 1

[0054] (1) Preparation of magnesium chloride spherical carrier

[0055] In a 250ml glass reactor equipped with a reflux condenser, a mechanical stirrer and a thermometer, and fully replaced by high-purity argon, add 18.3ml of dehydrated alcohol, 10.6g of anhydrous magnesium chloride (molar ratio dehydrated alcohol: anhydrous magnesium chloride =2.8:1, heat up under stirring, add 60ml of inert solvent (a mixture of methyl silicone oil and liquid paraffin in a volume ratio of 1:1) after the magnesium chloride is completely dissolved, stir to disperse and emulsify it for 15min (pre-dispersion), and the stirring speed is 600rpm, and maintain the temperature at 120°C. In another reactor with a mechanical stirrer with a volume of 250ml, first add 60ml of inert solvent (identical to the composition of the above inert solvent), preheat to 120°C, and prepare the above-mentioned The mixture was quickly transferred to the second reactor, maintained at a temperature of 120°C, and stirred ...

Embodiment 2 and Embodiment 3

[0061] Change the molar ratio of absolute ethanol to magnesium chloride in the preparation of magnesium chloride alcoholate in Example 1 to 3.5:1 and 6:1, and other conditions and methods are the same as in Example 1. The composition of the magnesium chloride alcoholate carrier is MgCl 2 2.56C 2 h 5 OH and MgCl 2 2.67C 2 h 5 OH, the percentages of titanium and ester in the catalyst are respectively Ti=2.21%, ester=3.72% and Ti=2.87%, ester=4.23%, and the specific surface area is 256m 2 / g and 224m 2 / g. Liquid-phase butene-1 bulk polymerization is the same as in Example 1, and the results are listed in Table 1.

Embodiment 4

[0063] Change the final dispersion speed in the preparation of magnesium chloride alcoholate in embodiment 1 to 1000rpm, and other conditions and methods are all the same as in embodiment 1. The composition of the magnesium chloride alcoholate carrier is MgCl 2 2.32C 2 h 5 OH, Ti in the catalyst = 1.91%, ester 4.50%, specific surface area 249m 2 / g. Liquid-phase butene-1 bulk polymerization is the same as in Example 1, and the results are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com