Guide rope pulley assembly

A pulley assembly, pulley technology, applied in building components, walls, buildings, etc., can solve problems such as guide wire damage, damage, and hoisting device failure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

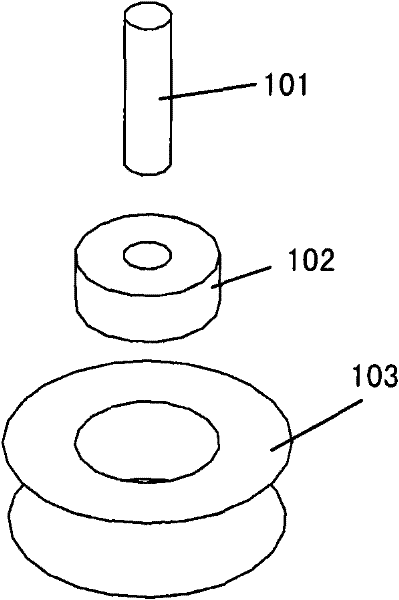

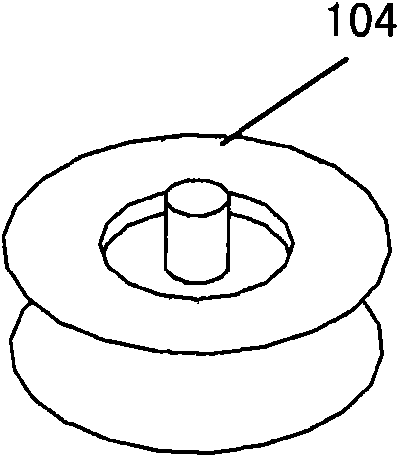

[0035] Such as figure 1 and figure 2 As shown, the pulley 104 includes a shaft 101 , a bearing 102 and a concave wheel 103 , and an annular groove is formed on the outer circumference of the concave wheel 103 . Such as figure 2 As shown, the concave wheel 103 is installed on the shaft 101 through a bearing, and the concave wheel 103 rotates around the shaft 101, and the shaft 101 is used to install the entire pulley. Both the base pulley and the rotating part pulley described later adopt the structure of the pulley 104, but in an embodiment of the present invention, the base pulley and the rotating part pulley are pulleys with different diameters.

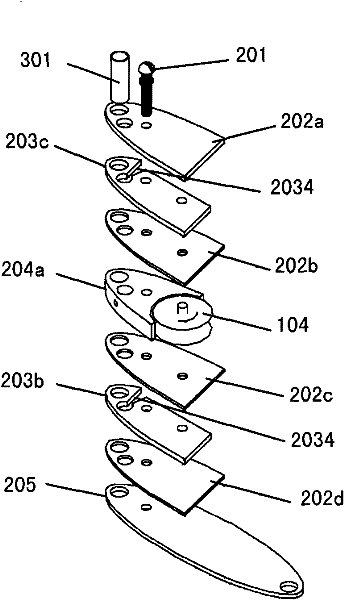

[0036] Such as image 3 and Figure 4 As shown, the pulley base 10 includes a pulley base including a first base clip 202a, a second base clip 202b, a third base clip 202c and a fourth base clip 202d, and also includes a first connecting bracket The piece 203a and the second connecting piece 203b, as well as the base rear cl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com