Confirmation method of working curved surface of window lifter guide rail of vehicle door

A determination method and technology of the window-swing machine, applied in the direction of door/window accessories, doors, vehicle parts, etc., can solve the problem of unstable operation of the window-swing machine.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

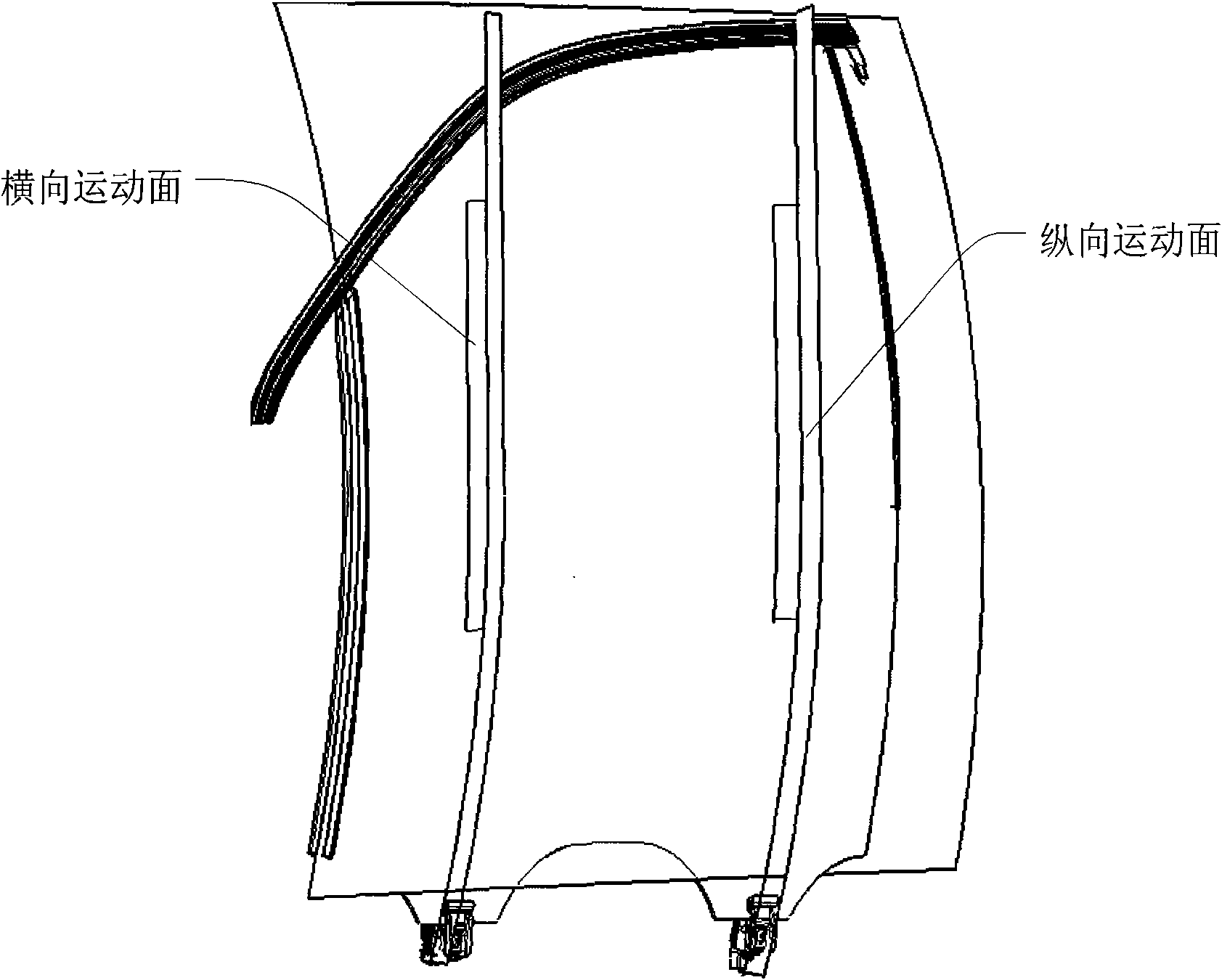

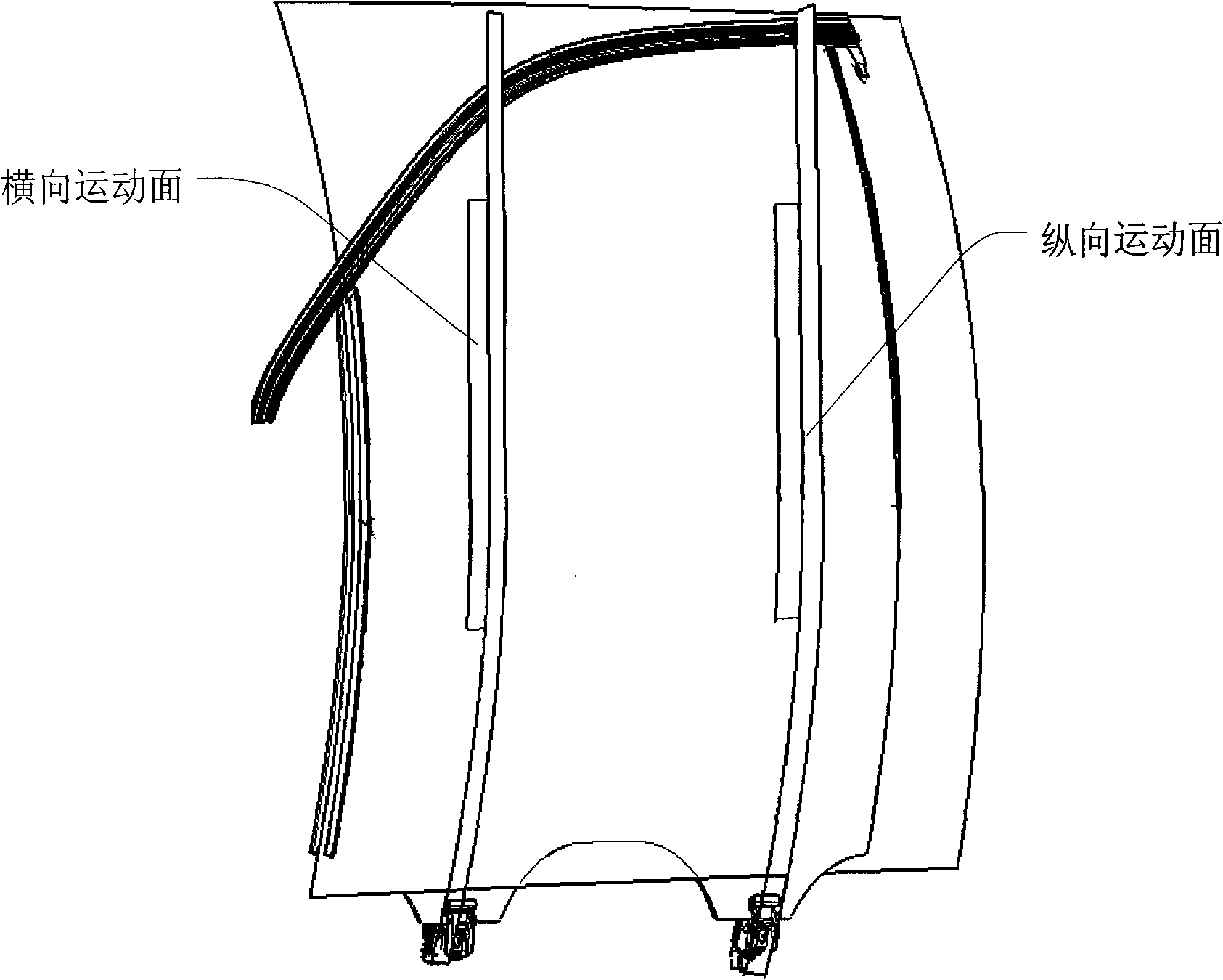

[0013] Such as figure 1 As shown, take the design of the guideway surface of a certain vehicle as an example. Since the guide groove of the car door and the shape of the glass have been given in the body, the first problem in the design of the window shaker is to determine the position of the slider. The window shaker is divided into single guide rail and double guide rail.

[0014] For the determination of the position of the single-rail slider, the effect of the resistance moment on the glass moving up and down should be considered. The principle is that the position of the fulcrum of the slider should maintain a moment balance during the sliding process: ∑M=0 is the principle. In these moments There are the gravity of the glass itself and the resistance of the glass movement, but one point of the guide rail is the center of moment, and one of the fulcrums of the double guide rail is the center of moment. In this way the position of the slides of the single and double guid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com