An automatic monitoring method for bridge pushing based on stakeout robot

An automatic monitoring and robot technology, which is applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of not being able to reflect the deviation of the jacking position in real time, the danger of high-altitude observation operations, etc., and achieve the goal of reducing labor costs and simplifying work procedures Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

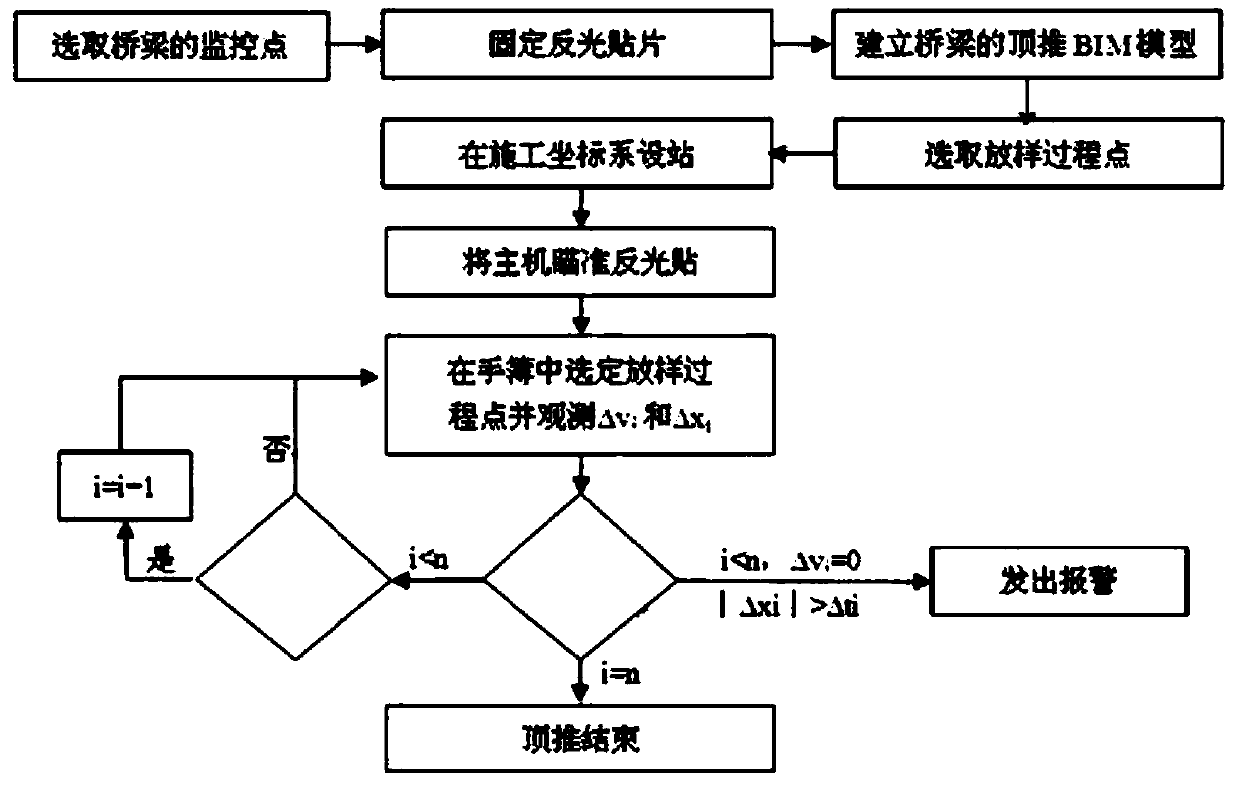

[0028] Such as figure 1 As shown, a bridge push automatic monitoring method based on a lofting robot includes the following steps: (1) select a monitoring point of the bridge, and fix a reflective patch at this point;

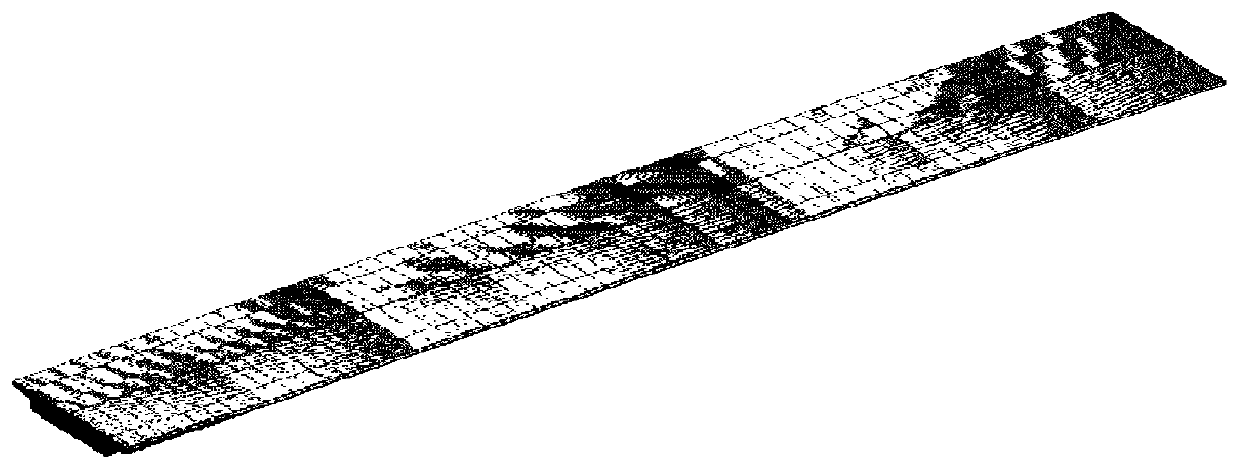

[0029] (2) Import the BIM model into the stakeout robot, and select several stakeout process points according to the monitoring points;

[0030] (3) The stakeout robot sets up a station on the construction coordinate system, and aims at the reflective patch for stakeout;

[0031] (4) During the pushing process, observe the lateral deviation displayed on the handbook of the stakeout robot, and issue an early warning when the deviation exceeds the limit.

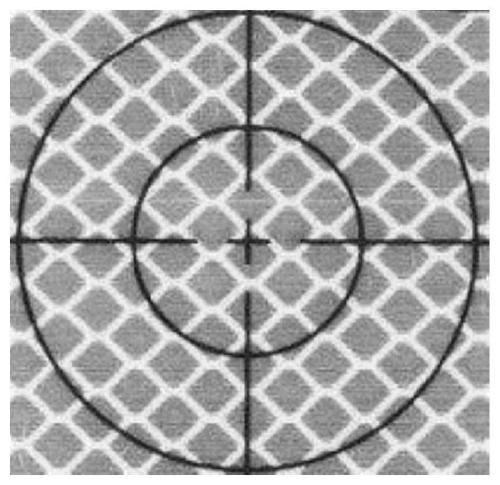

[0032] Such as figure 2 As shown, the reflective patch is fixed at the monitoring point of the bridge. Since the specific project is a straight-line push, only two monitoring points are set under the right pick arm of the end and the end, so it is assumed that two stakeout robot instruments monitor them res...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com