Crack closing stress determination method based on axial stress response

A technology of axial stress and closed stress, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc., can solve the problem of inconclusive stress threshold reliability, and solve the problem of determining the compaction point , the effect of improving the accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0052] In order to further understand the features, technical means, and specific objectives and functions achieved by the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

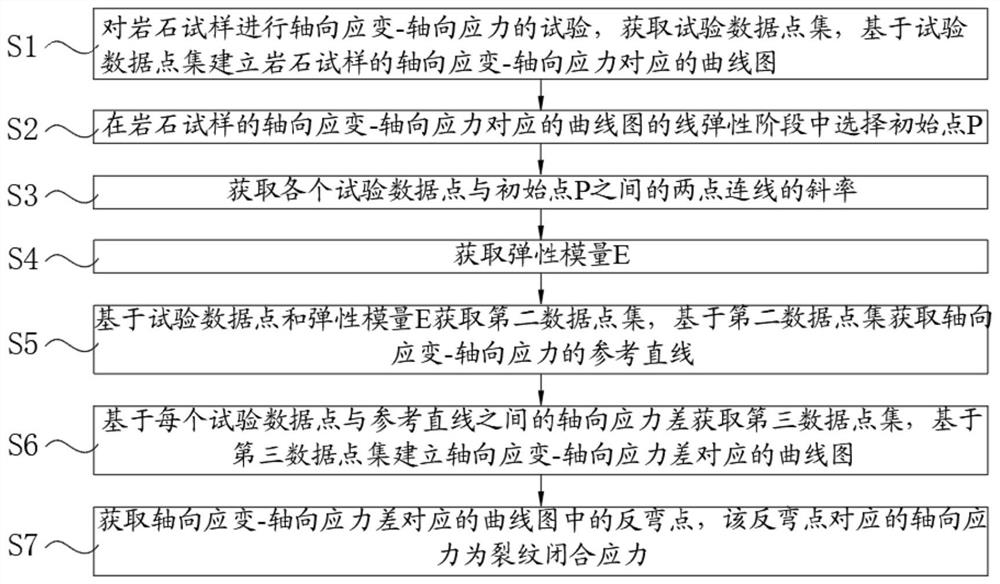

[0053] figure 2 is a schematic flowchart of a method for determining crack closure stress based on axial stress response provided by an embodiment of the present invention, as shown in figure 2 As shown, the method for determining the crack closure stress based on the axial stress response specifically includes the following steps:

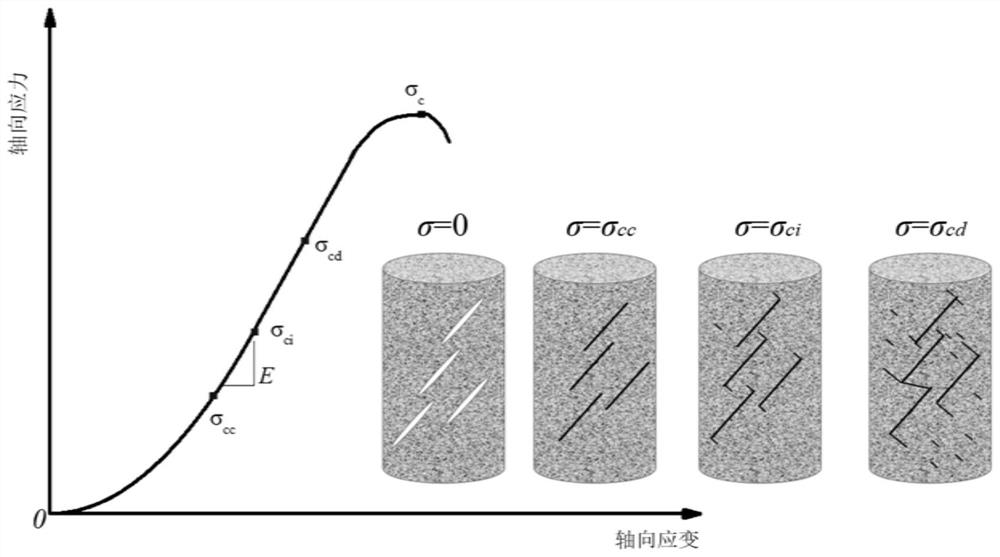

[0054] Step S1, carry out the compression test of the axial strain-axial stress relationship on the rock sample, and obtain the test data point set Based on the test data point set, the corresponding curve diagram of the axial strain-axial stress relationship of the rock sample is established, such as image 3 shown;

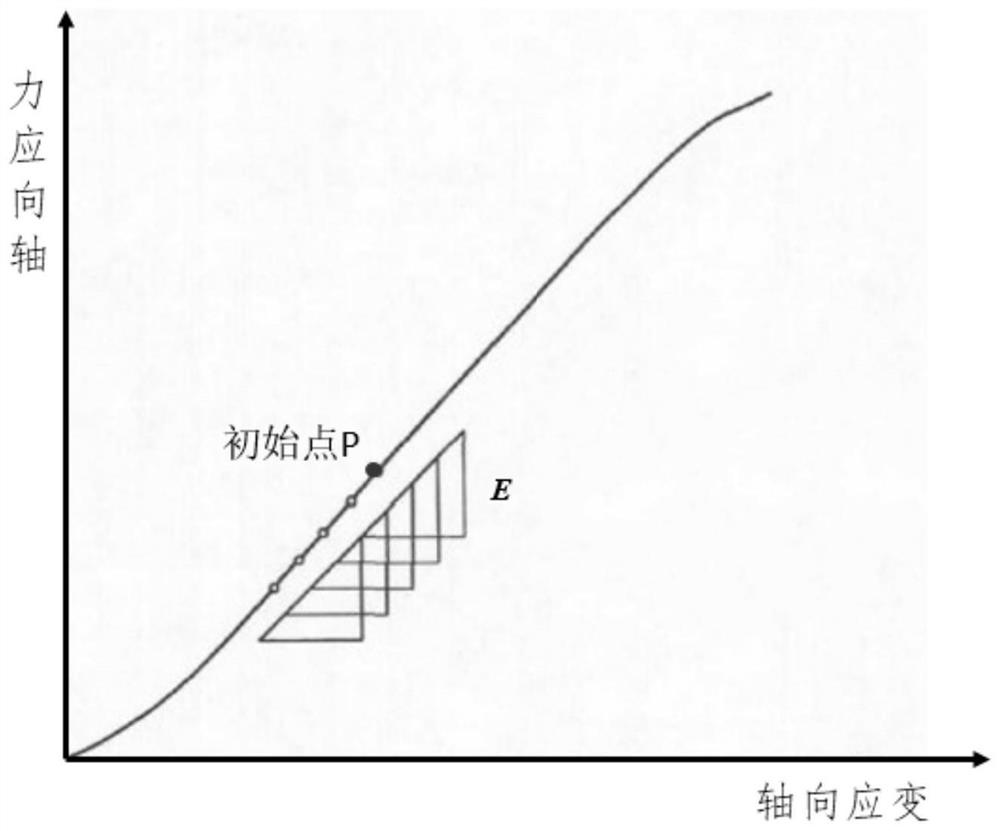

[0055] Step S2, select the initial point P(ε p ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com