Multifunctional civil stop valve

A stop valve, multi-functional technology, applied in the direction of lifting valve, valve device, engine components, etc., can solve the problems of particles, poor viscosity adjustment performance, large fluid resistance, large opening and closing, etc., to meet the requirements of multi-functional, structural Formal scientific and reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

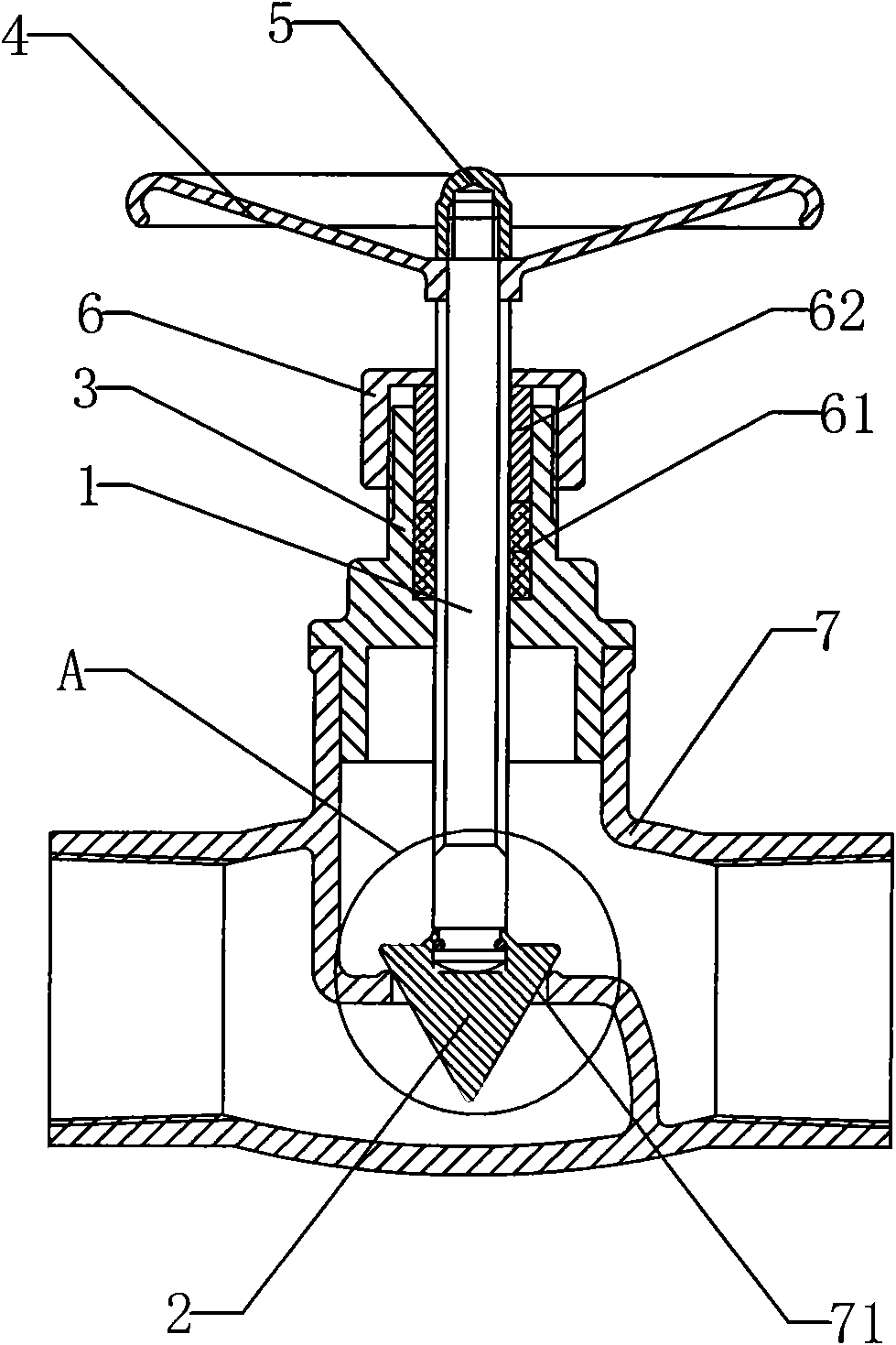

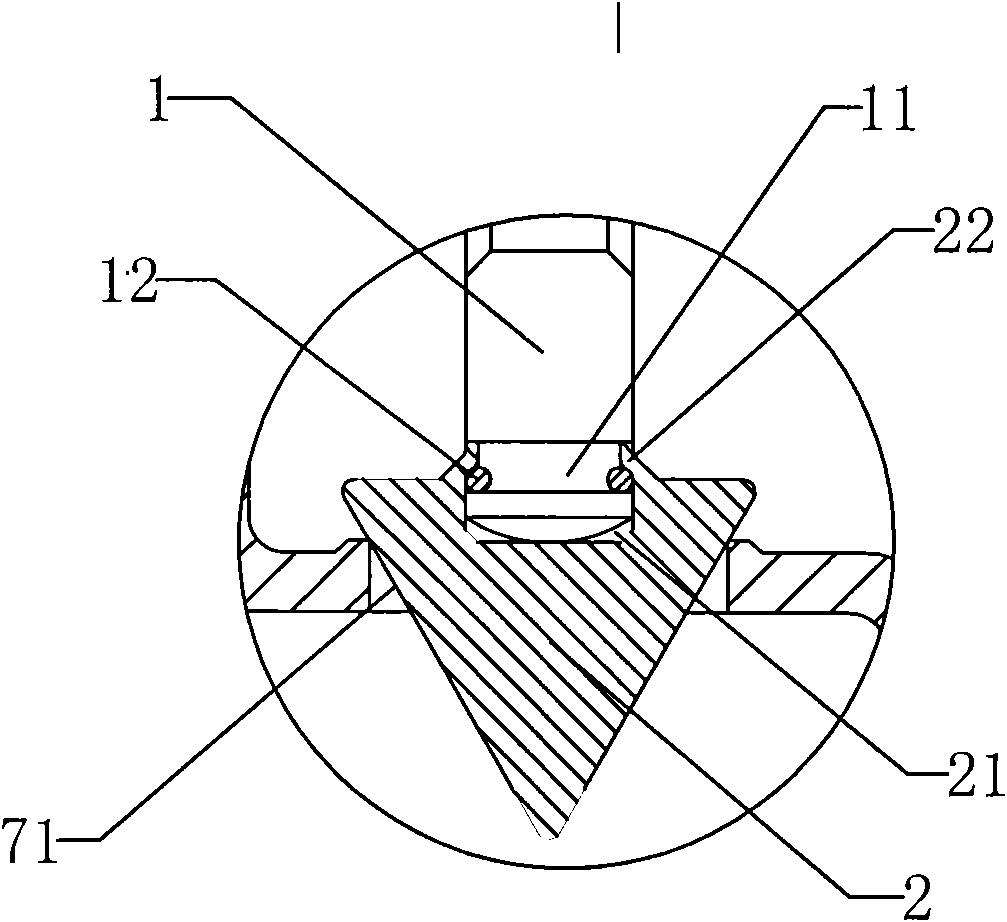

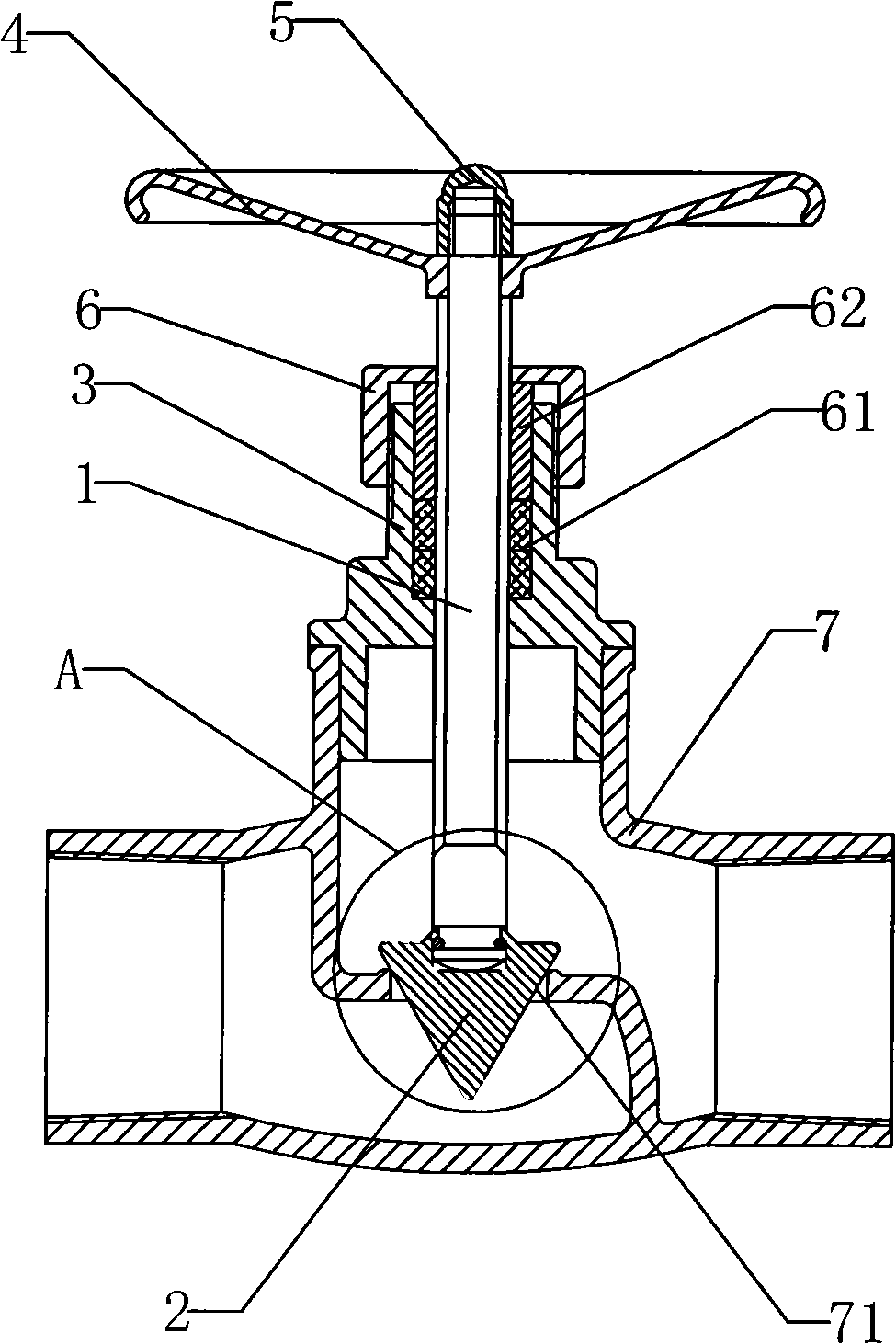

[0014] The multi-functional civil shut-off valve of the present invention will be further described below in conjunction with the accompanying drawings of the description.

[0015] see figure 1 and figure 2 , a multifunctional civil shut-off valve of the present invention includes a valve body 7, a valve stem 1 whose lower part is placed inside the valve body 7, and a conical disc 2 fixed to the bottom end of the valve stem 1 through a buckle-type connection structure. The coupling structure includes an annular groove 11 at the bottom of the valve stem 1 and a groove 21 at the center of the top end of the valve disc 2. A traveler 12 is installed inside the annular groove 11, and a buckle joint extends upward from the top of the valve disc 2. part 22, the fastening part 22 wraps the traveler 12 in the annular groove 11, the valve cover 3 is arranged in the middle of the valve stem 1 and the lower end of the valve cover 3 is connected with the upper part of the valve body 1, t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com