Portable shaft vibration gauge

A measuring instrument and portable technology, which is applied in measuring devices, instruments, and measuring ultrasonic/sonic/infrasonic waves, etc., can solve the problems of delayed processing timing, blank shaft vibration signals, real-time and convenient monitoring of unfavorable rotating machinery shaft vibration, etc., to achieve Easy to carry, cost saving, small volume and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

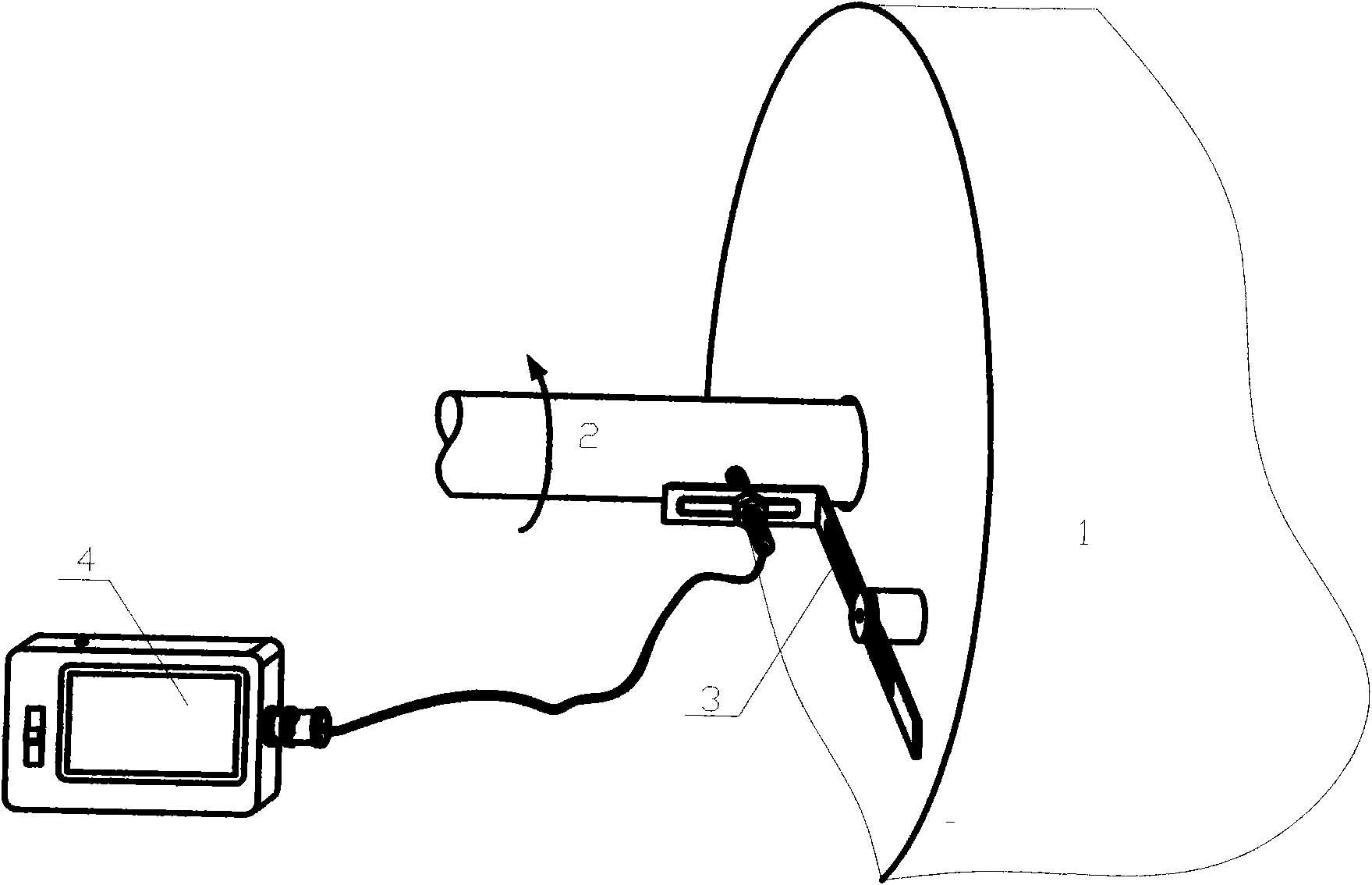

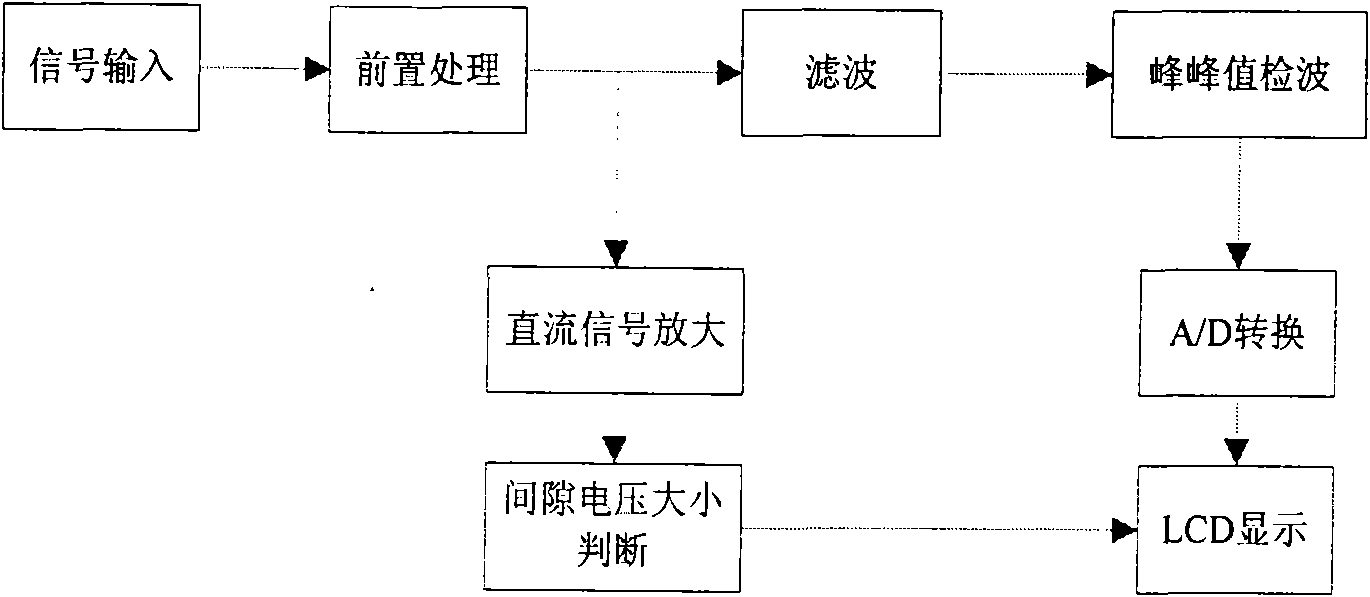

[0022] A portable shaft vibration measuring instrument is composed of a magnetic sensor 3 and a hand-held shaft vibration signal processing device 4 , the output end of the magnetic sensor 3 is connected to the input end of the hand-held shaft vibration signal processing device 4 .

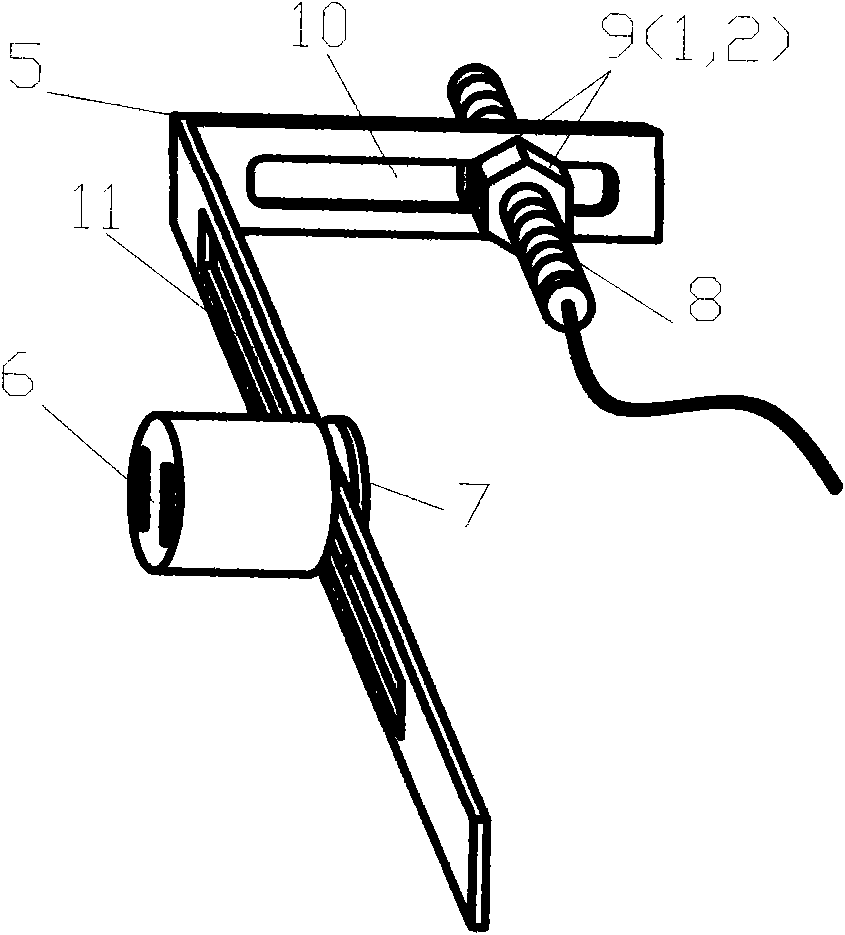

[0023] Described magnetic sensor 3 comprises: L-shaped support 5, is provided with sensor chute 10 on an arm of L-shaped support 5, is slidably connected with sensor 8 in sensor chute 10, and described sensor 8 is screwed with it And the first nut 91 and the second nut 92 that are positioned at an arm both sides of described L-shaped support 5 are fixed; On the other arm of L-shaped support 5, be provided with magnetic base chute 11, on the magnetic base slide A magnetic base 6 is slidably connected in the slot 11, and the magnetic base 6 is fixed by a third nut 7 threaded therewith. The magnetic base 6 enables the shaft vibration sensor 8 to be arranged on the steel surface 1 close to the rotatin...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap