Ceramic metal halide lamp shell

A metal halide and light bulb technology, applied in the field of ceramic light sources, can solve the problems affecting the working efficiency and life of the lamp, the erosion of ceramic metal halide lamps, the loss of halogens, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

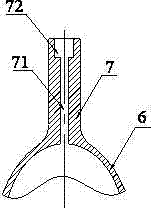

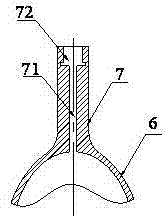

[0032] Such as figure 2 As shown, the present invention discloses a ceramic metal halide bulb shell, which includes a discharge chamber 6 and capillary tubes 7 arranged at both ends of the discharge chamber 6. The capillary tube 7 includes a connected inner tube section 71 and a welding groove 72. The inner tube section 71 is close to In the discharge chamber 6 , the welding groove 72 is located at the end surface, and the inner diameter of the welding groove 72 is larger than that of the inner pipe section 71 , and the welding groove 72 realizes the airtight sealing of the discharge chamber 6 by filling the solder 73 . In this embodiment, the inner diameter of the welding groove 72 is in the range of 1 to 4 mm, the depth is in the range of 1-4 mm, and the inner diameter of the inner pipe section is in the range of 0.4-1.5 mm.

[0033] The cold end ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com