Assembling method of clamp for assembling tool box

An assembly tool and assembly method technology, which is applied to manufacturing tools, assembly machines, workpiece clamping devices, etc., can solve the problems of assembly difficulty, bumping assembly personnel, and insecurity, and achieve rapid assembly, improve assembly efficiency, and assembly efficiency. improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

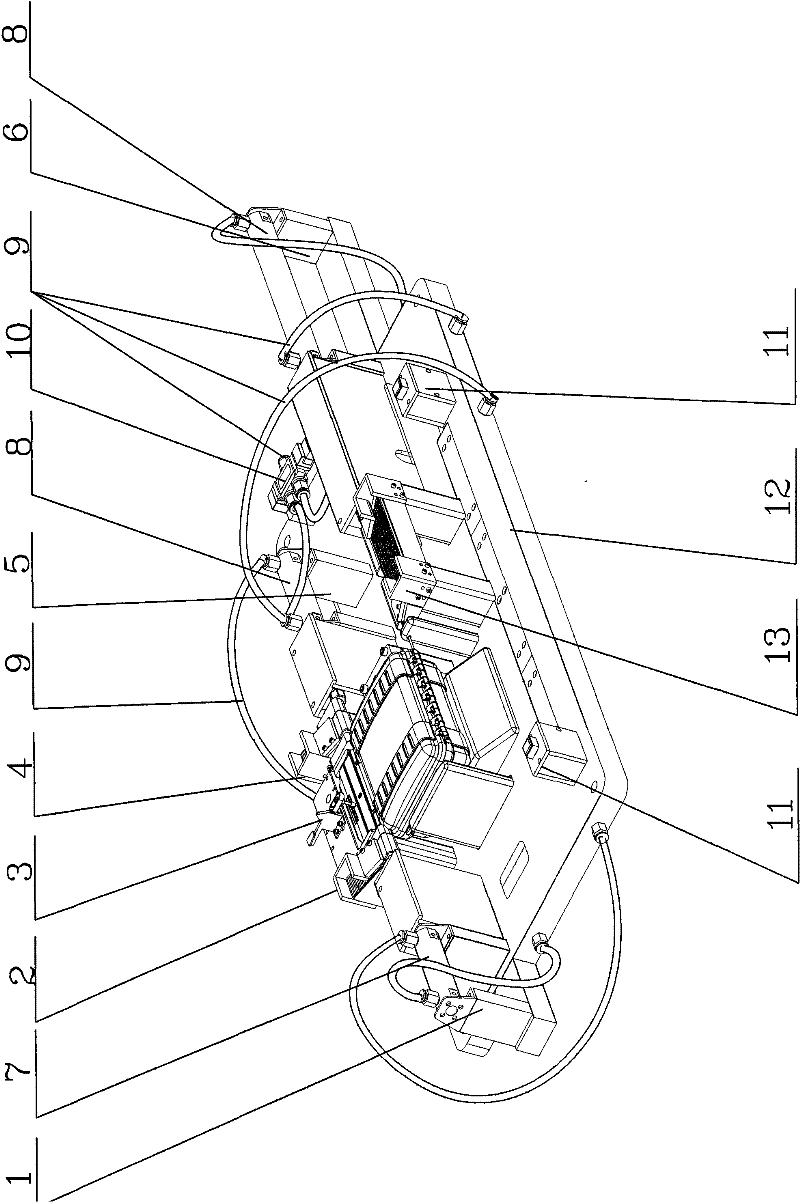

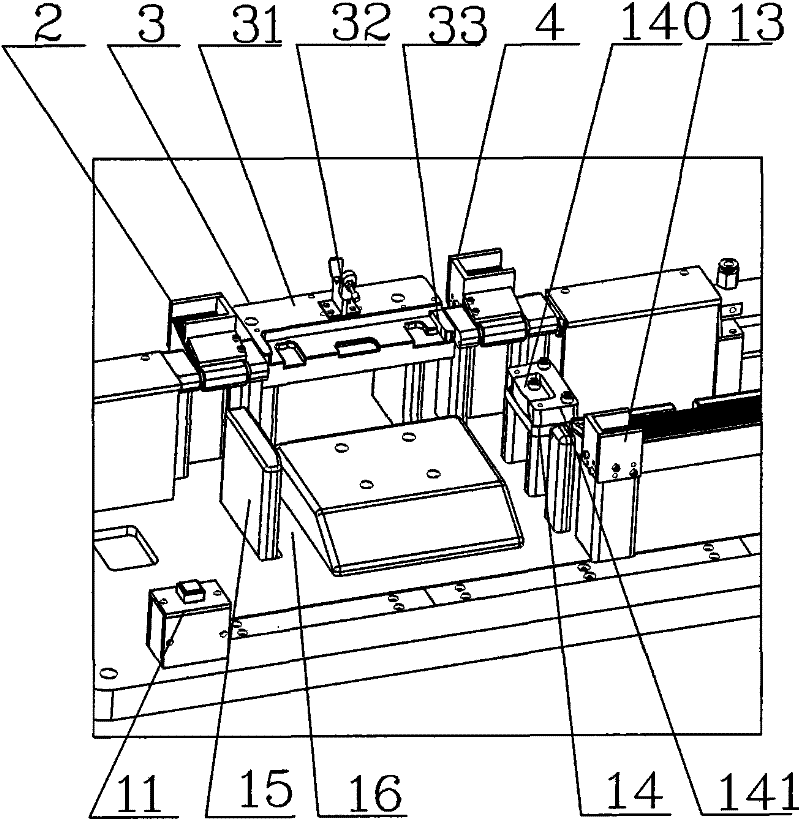

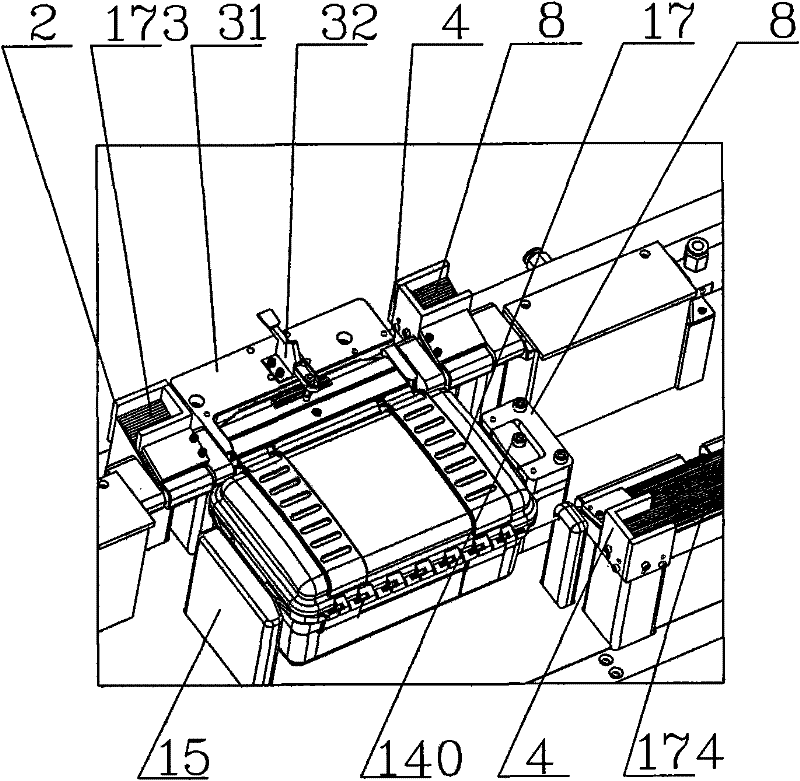

[0040] The present invention will be further described below in conjunction with the accompanying drawings of the description.

[0041] Such as Figures 1 to 4As shown, a fixture for assembling a tool box, the fixture includes a base 12, the base 12 is provided with an assembly section 16, and a fastening device is provided in the assembly section 16, and the fastening device It includes a front fastening device 3 located at the front of the assembly section 16 and two side fastening devices located at both sides of the assembly section 16 . The front fastening device 3 includes a fixing table 31 on which a quick fixing clip 32 and a first adjustable fastening device 33 are arranged. The quick fixing clip 32 is rotatable, and by rotating the quick fixing clip 32 , the fastening or loosening of the assembly parts can be realized. The first adjustable fastening device 33 includes a spring (not marked), a rotating shaft (not marked), a swing rod (not marked), the rotating shaft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com