Mounting system special for accurately machining two supporting holes of elastic tube assembly and method

A precision processing and installation system technology, applied in the direction of support, metal processing equipment, metal processing machinery parts, etc., to achieve the effect of fast and precise positioning and U-turn installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

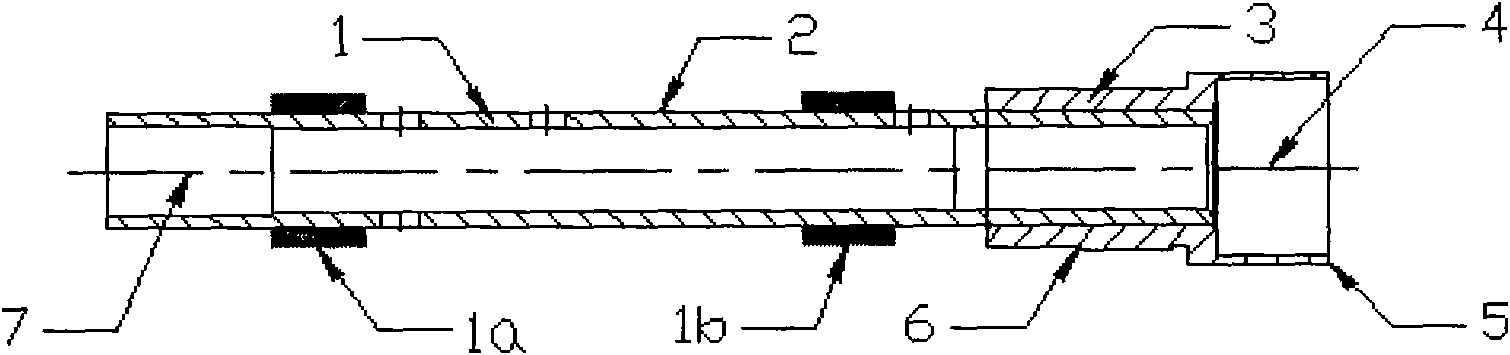

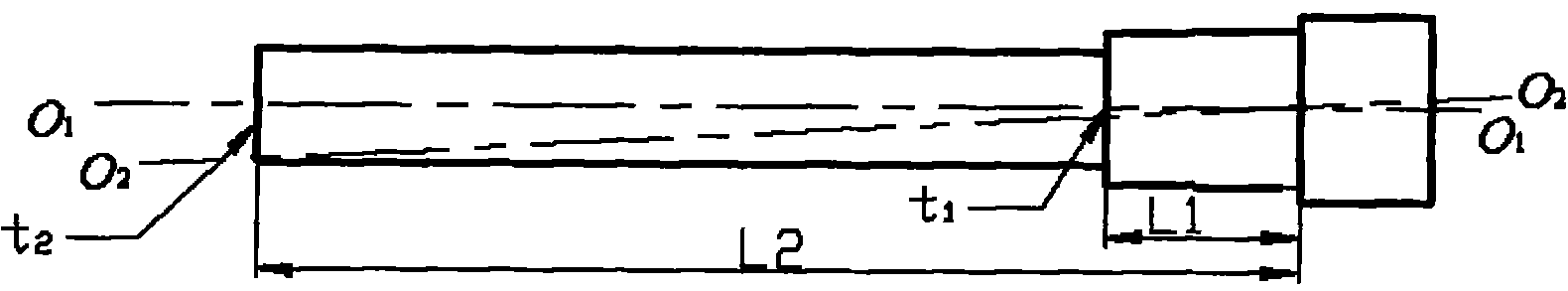

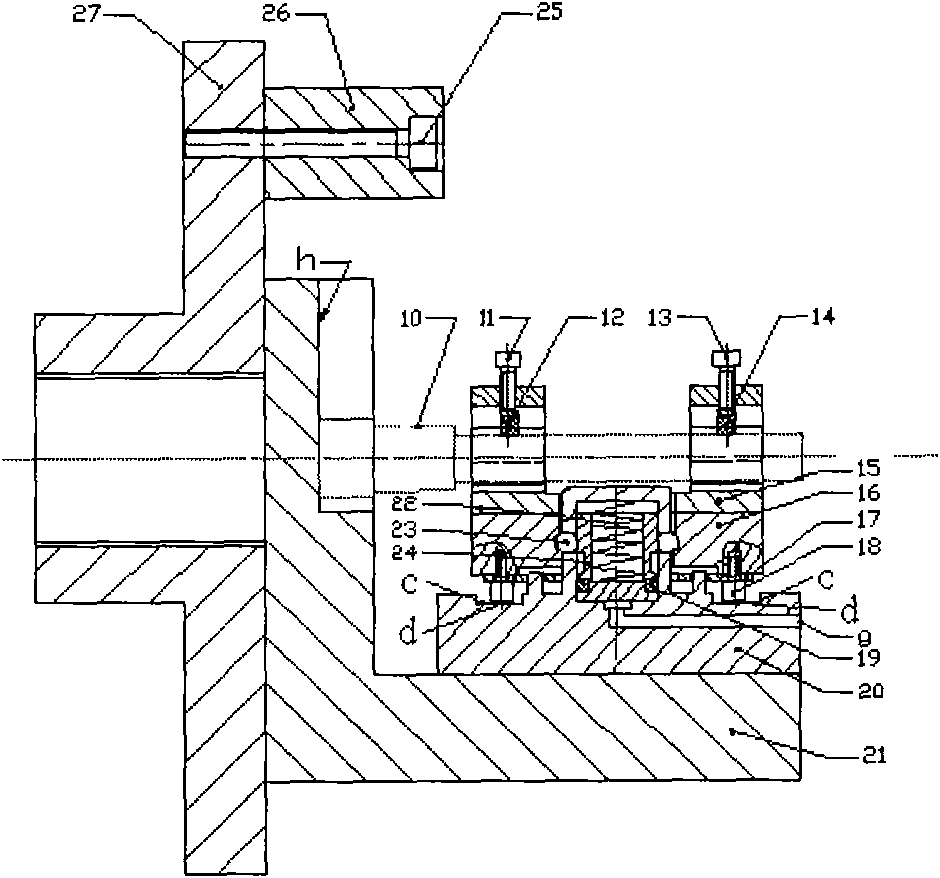

[0022] Such as image 3 As shown, a special installation system and method for precise machining of two supporting holes of an elastic tube assembly is composed of a workpiece initial installation mechanism, a quick positioning mechanism and a connection balance mechanism. The workpiece initial installation mechanism is composed of an initial positioning element 15, a support plate 16 and a clamping mechanism. Two V-shaped surfaces with a certain distance are processed on the initial positioning element 15, and are parallel to the bottom plane d of the base part, elastic The pipe assembly is placed on the positioning element 15 through the outer circles 1a and 1b, and is clamped by the clamping mechanism to form the workpiece / fixture as a whole; The positioning characteristic surface e matched with the position finder is composed of the positioning element 17 connected with the base part 16 and the pneumatic clamping mechanism, and the positioning plane d on the support plate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com