Annular water-blowing device

An annular and annular groove technology, applied in furnaces, heat treatment equipment, quenching agents, etc., can solve problems such as troubled technicians, inconvenient handling, and unclean water blowing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

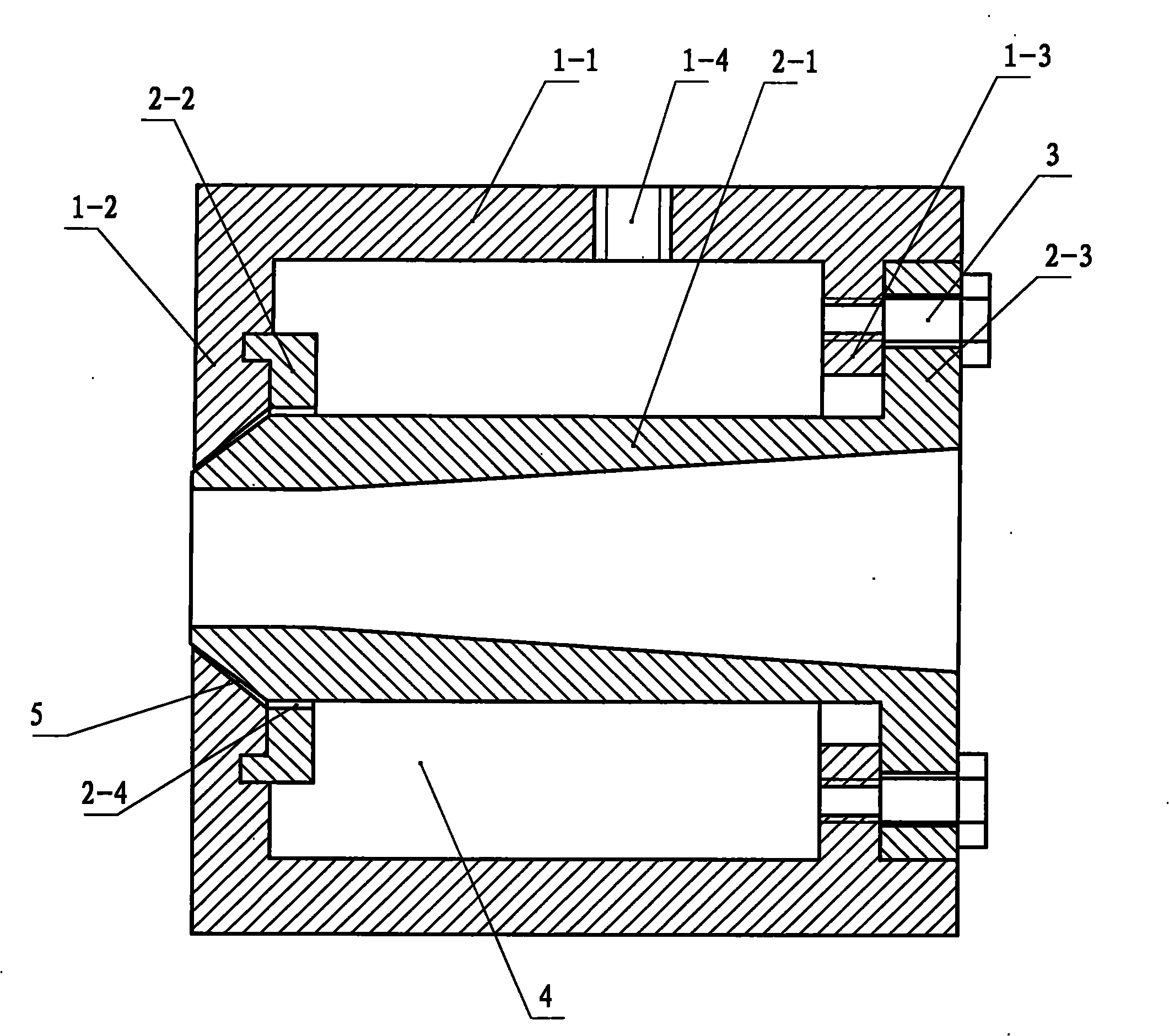

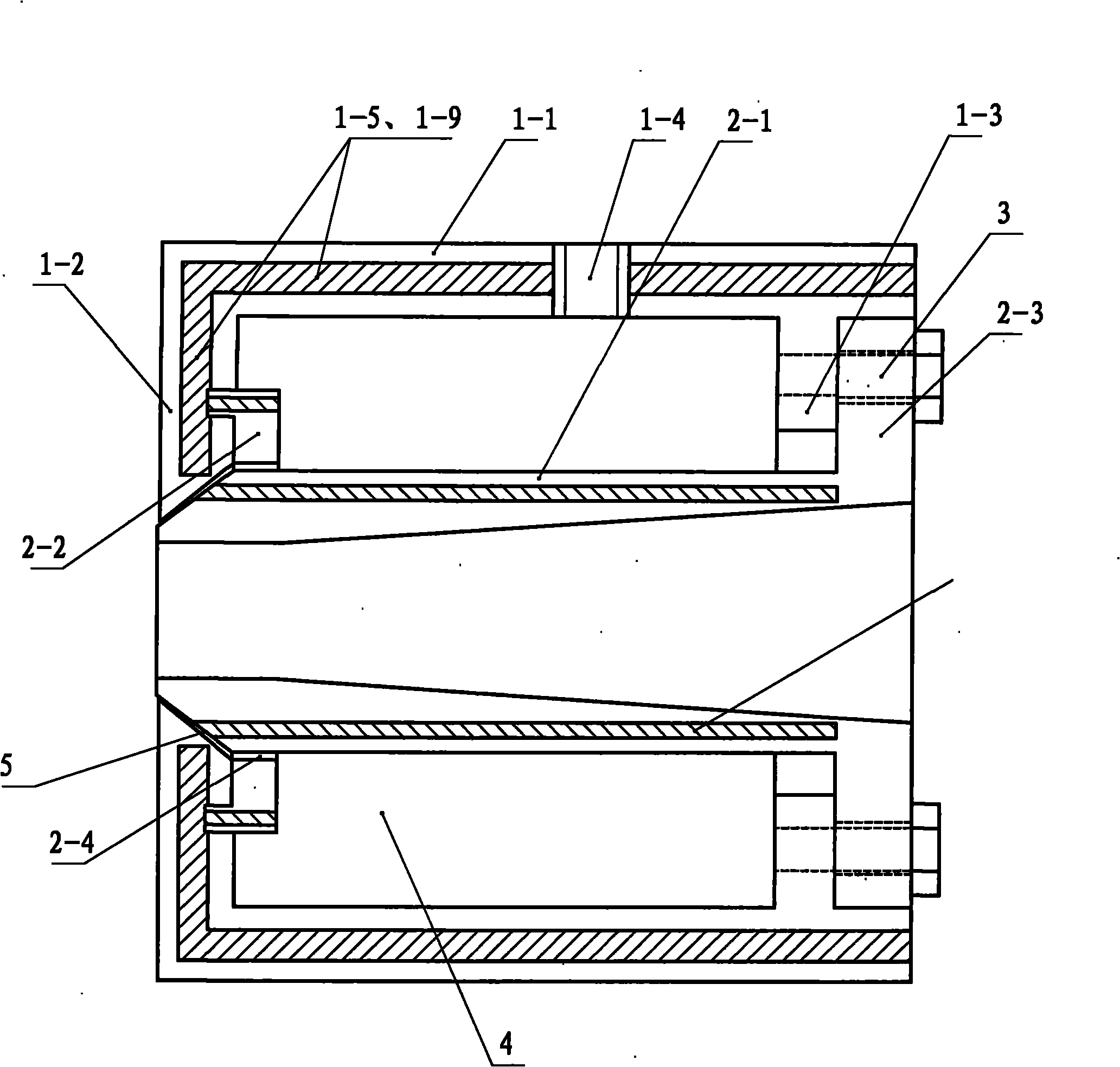

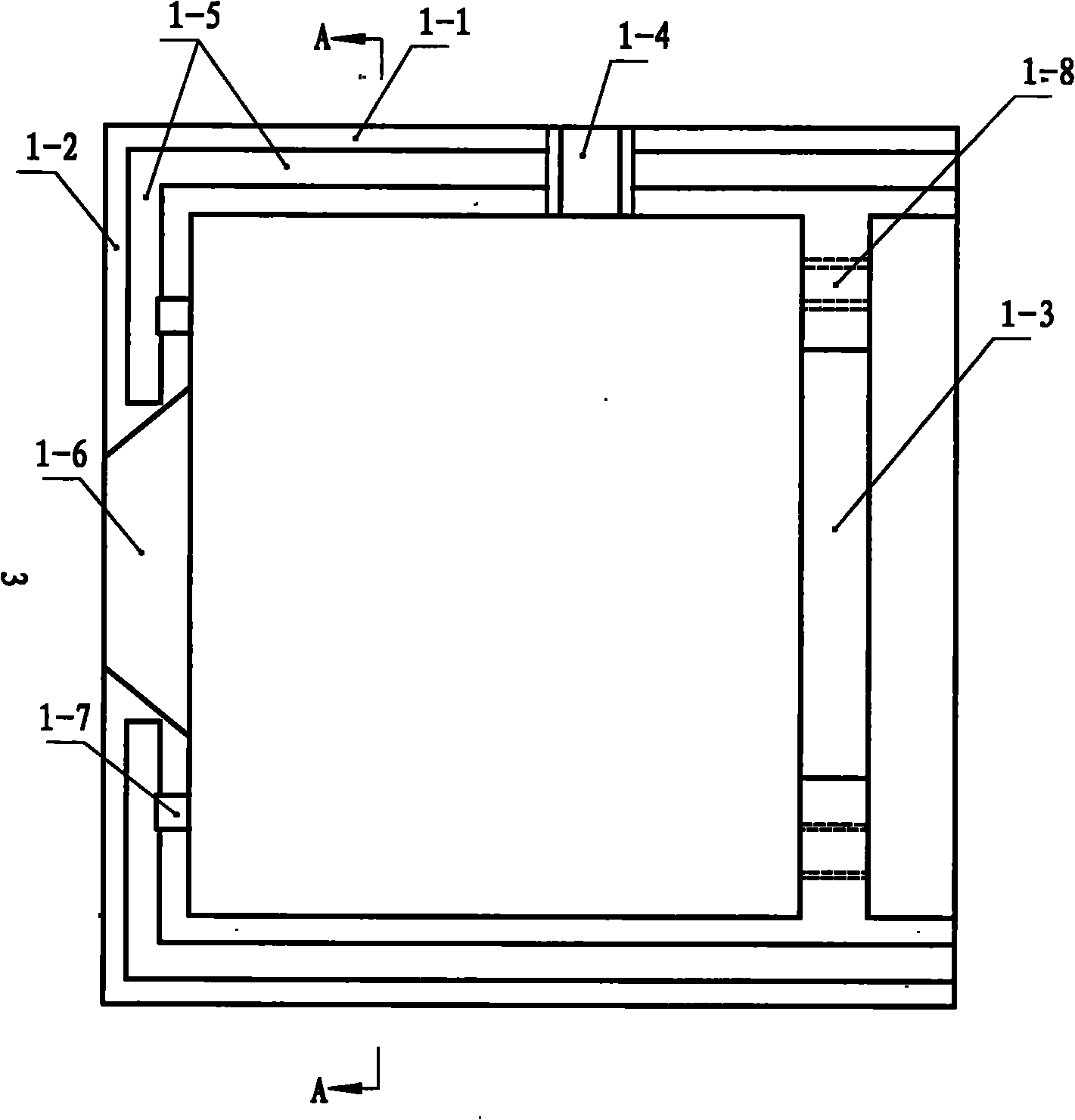

[0035] Embodiment one: see Figure 1-Figure 14 , a ring-shaped water blowing device in the figure, which contains a hollow inner sleeve and a hollow outer sleeve. The two ends of the inner tube body of the outer sleeve are respectively provided with a connecting plate and a positioning plate, and the outer two ends of the tube body of the inner sleeve There are matching connecting discs and positioning discs at the end, and the connecting discs of the outer sleeve and the inner sleeve are connected together by fasteners. There are bolt holes on the connecting discs of the outer sleeve and the inner sleeve, and the positioning discs of the outer sleeve and the inner sleeve are connected together. A matching positioning structure is provided between them; an annular air chamber is formed inside the outer sleeve body and the inner sleeve body; the side wall of the outer sleeve is provided with an air inlet to communicate with the air chamber; the middle part of the positioning pla...

Embodiment 2

[0044] Embodiment two: see Figure 15 , the second embodiment is basically the same as the first embodiment, and the similarities will not be repeated. The difference is that the annular groove on the inner surface of the positioning plate of the outer jacket in the second embodiment is a trapezoidal groove with an outer width and an inner narrowness. The annular convex edge of the outer surface of the positioning plate of the inner sleeve is a trapezoidal convex edge matching the above-mentioned trapezoidal groove, and the positioning plate and the connecting plate of the inner sleeve are respectively press-fitted on the positioning plate and the connecting plate of the outer sleeve in the same direction. plate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com