Elastic clamping piece and liquid crystal module with same

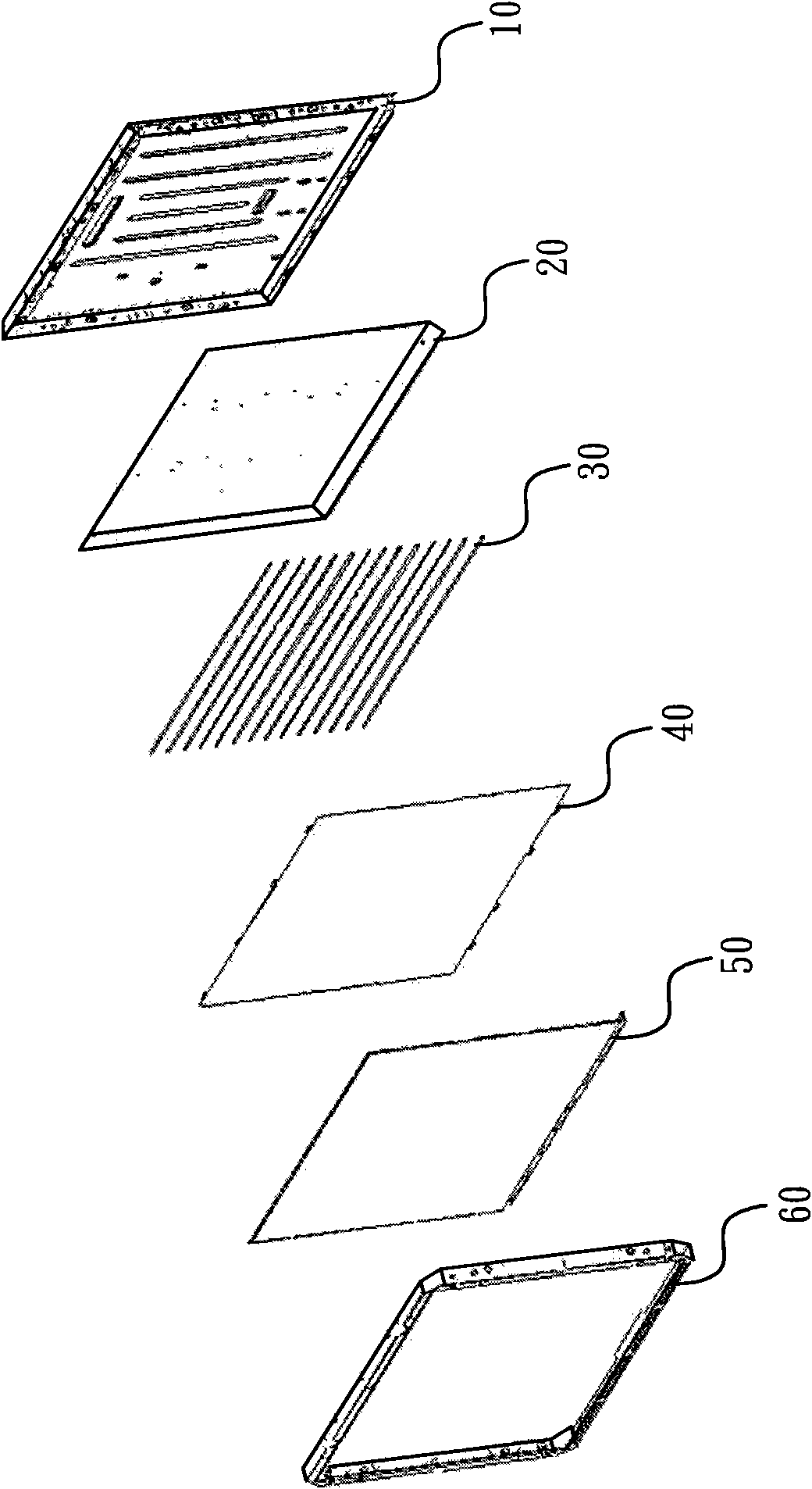

A technology of liquid crystal module and card firmware, applied in the field of flat panel display, can solve the problems of large thickness of liquid crystal module, poor impact resistance, complicated installation process, etc., and achieve the effects of simple assembly, reliable connection and good impact resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

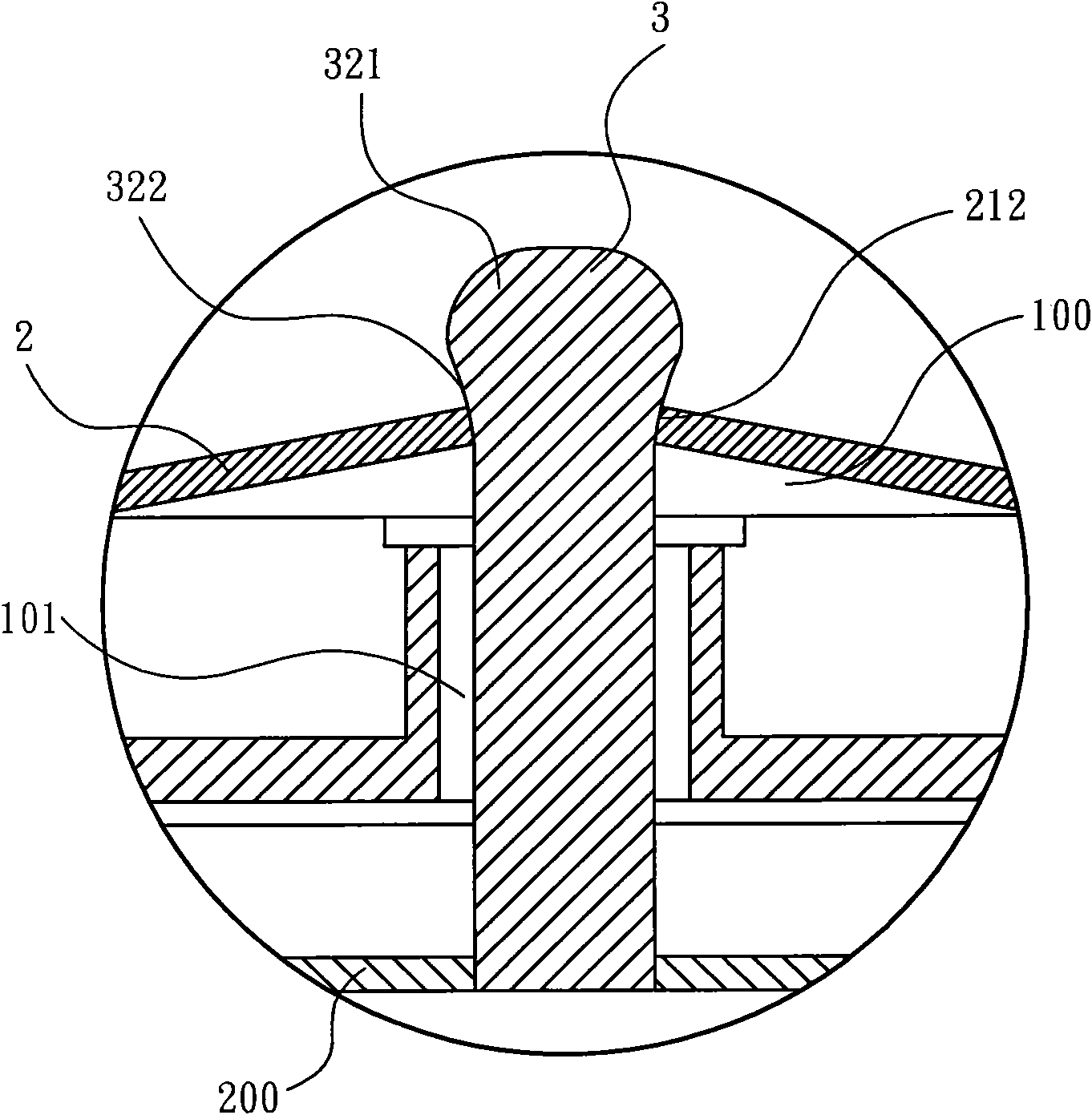

[0035] refer to Figure 2 to Figure 5 , the elastic clip 1 of the present invention includes a symmetrically shaped elastic piece 2 and a cylinder 3 with an arc-shaped mating surface 31 . The arc-shaped mating surface 31 of the cylinder 3 can be a part of a sphere, or any arc that facilitates the head 32 of the cylinder 3 to pass through the elastic piece 2, which is determined by the actual use. In this embodiment, only the spherical fitting surface is taken as an example for illustration.

[0036] The elastic piece 2 in this embodiment is an elastic clip connected to the backboard 100 , made of elastic material and integrally formed from the backboard 100 by stamping. Specifically, an opening and two symmetrical tongues 21 inside the opening are punched out on the back plate 100 . The connecting portion 211 at one end of the tongue 21 is connected to the side wall of the aforementioned opening of the backboard 100 , and the other end has a stop portion 212 (integrated with...

no. 2 example

[0049] For the convenience of description, the same components as in the first embodiment also use the same symbols and names in the second embodiment, and detailed descriptions are omitted.

[0050] refer to Figure 6 and Figure 7 , The elastic clip 1 of the present invention includes a symmetrically shaped elastic piece 2 and a cylinder 3 with an arc-shaped mating surface 31 . The arc-shaped mating surface 31 of the cylinder 3 may be a part of a sphere, or any arc that facilitates the head 32 of the cylinder 3 to pass through the elastic piece 2 and be fixed. In this embodiment, only the spherical fitting surface is taken as an example for illustration.

[0051] The elastic sheet 2 in this embodiment is an elastic structure integrally formed from the back plate 100 by stamping. The connecting portion 211 at one end of the tongue 21 is connected to the side wall of the aforementioned opening of the back plate 100 , and the other end has a circular-arc bent stop portion 21...

no. 3 example

[0054] For the convenience of description, the same components as in the first embodiment also use the same symbols and names in the second embodiment, and detailed descriptions are omitted.

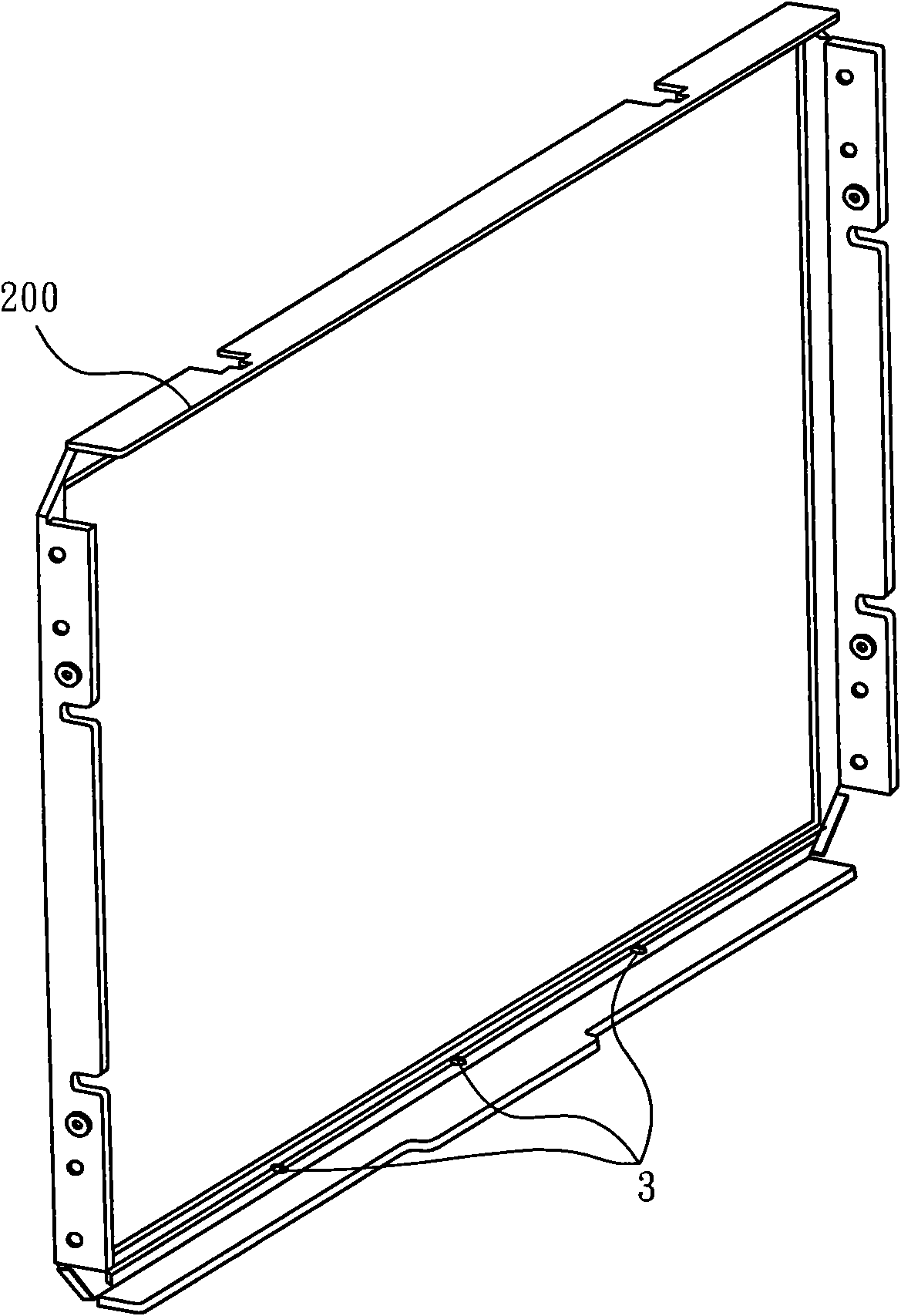

[0055] In the above two embodiments, the elastic piece 2 is directly stamped on the back plate 100 . However, shrapnel 2 is a prefabricated separate part. That is, an additional shrapnel is installed on the front frame or the back panel.

[0056] Such as Figure 8 As shown, the shrapnel 2 is made of elastic material, such as metal. It has two symmetrical connecting portions 211A on the same plane, a guiding portion 210 disposed between the connecting portions 211A, and a stop portion 212A located on the side of the guiding portion 210 away from the connecting portion 211A.

[0057] The connecting portion 211A can be in any shape, as long as the elastic piece 2 can be reliably installed on the backplane 100 . The method of connecting the elastic piece to the backboard may be various c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com