Tower for wind turbine

A technology for wind turbines and turbine blades, which is applied in the assembly of wind engines, wind engines, wind turbine components, etc. It can solve the problems of cost and quality reduction, increase the road transportation of parts at the bottom of the tower, and achieve improved strength and corrosion resistance performance, efficient production and maintenance, and reduced load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

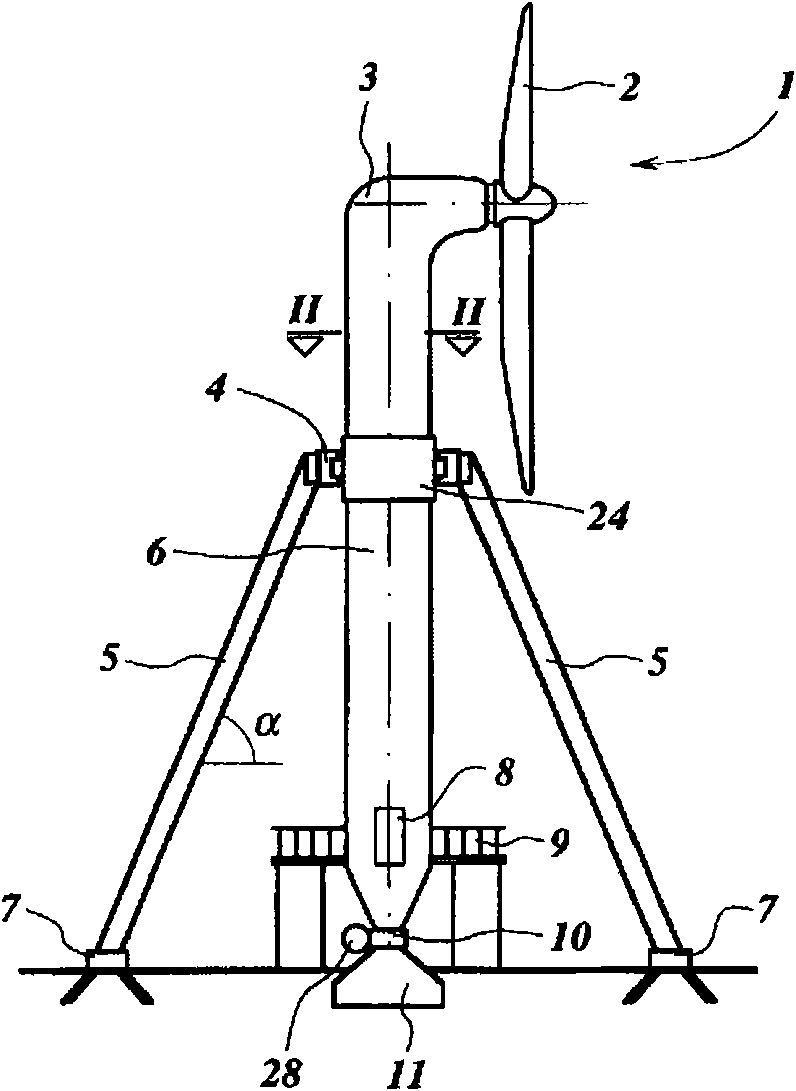

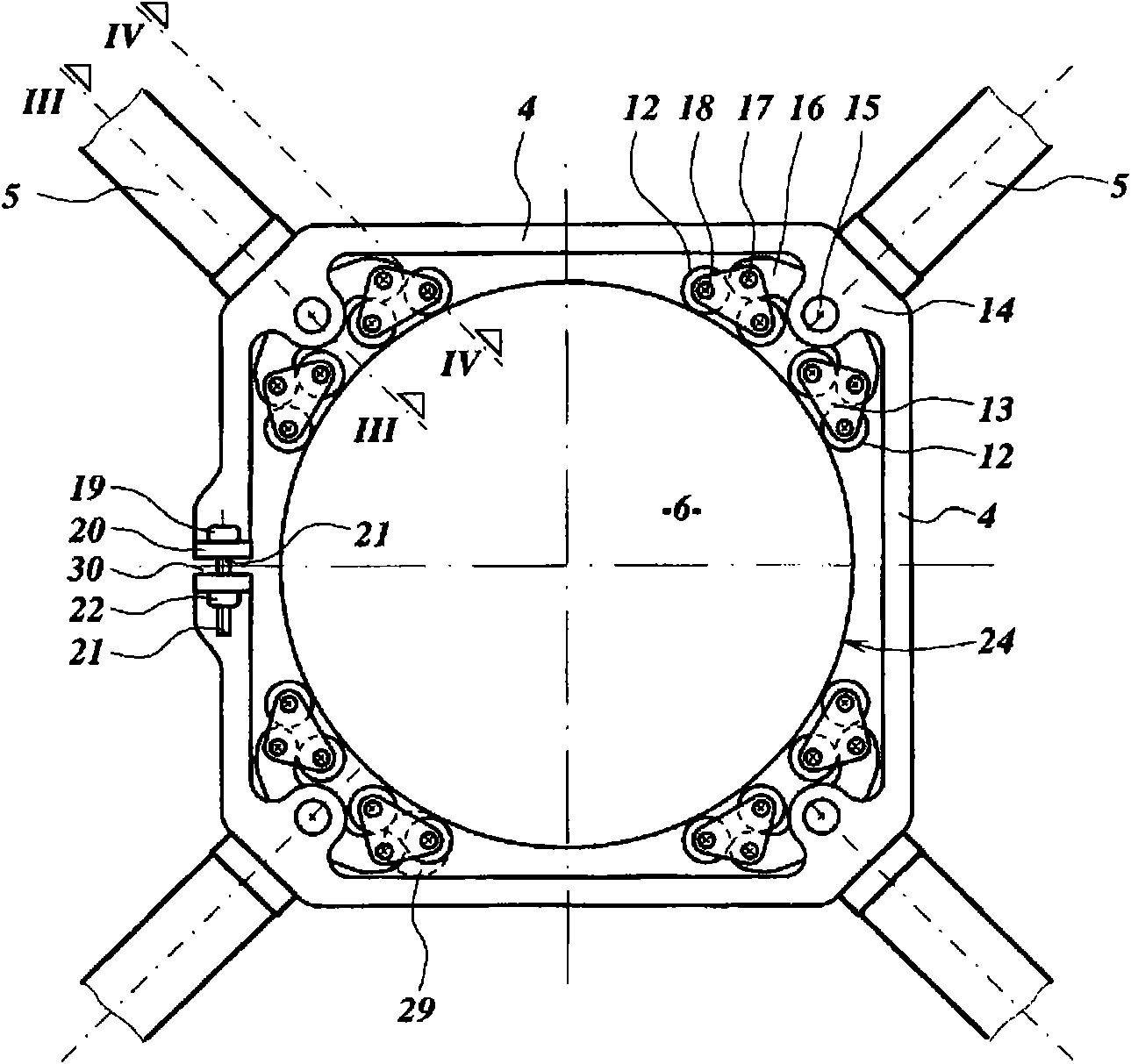

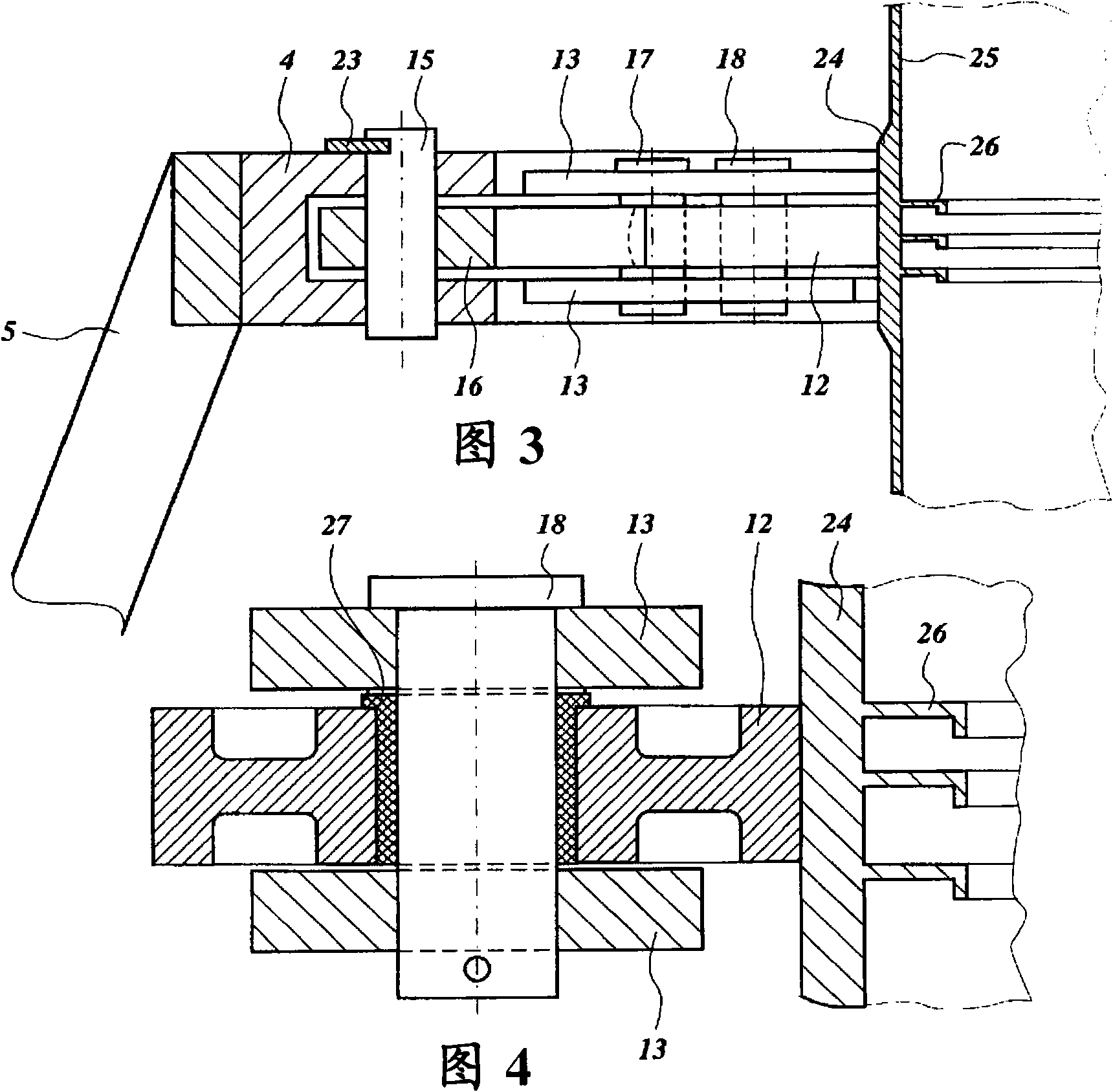

[0024] figure 1 A wind turbine 1 is shown with a blade 2 which is rotatable about a substantially horizontal axis of rotation. Bearings supporting the rotating shaft and blades 2 are mounted in a nacelle 3 mounted on top of a tower 6 . A base 11 supports the tower 6 and a bearing 10 between the base 11 and the tower 6 makes it possible to turn the tower 6 so that the blades 2 can face the wind. A support ring 4 surrounds the tower 6 at approximately half the height between the nacelle 3 and the ground and holds the tower 6 in an upright position. In the embodiment shown, four feet 5 support the support ring 4 and position the support ring 4 approximately at half the height of the housing 3, preferably at a height between one-third and two-thirds of the height of the housing 3 . In other embodiments, the number of legs 5 may be three or five or more.

[0025] The leg support 7 supports and holds the lower end of a leg 5 whose upper end is fixed to the support ring 4 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com