Three-jaw chuck

A three-jaw chuck and clamping structure technology, applied in the field of mechanical processing, can solve the problems of low pressure of deformation pressing screw and rear platen, cumbersome clamping adjustment, uneven force, etc. Reliable and even force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

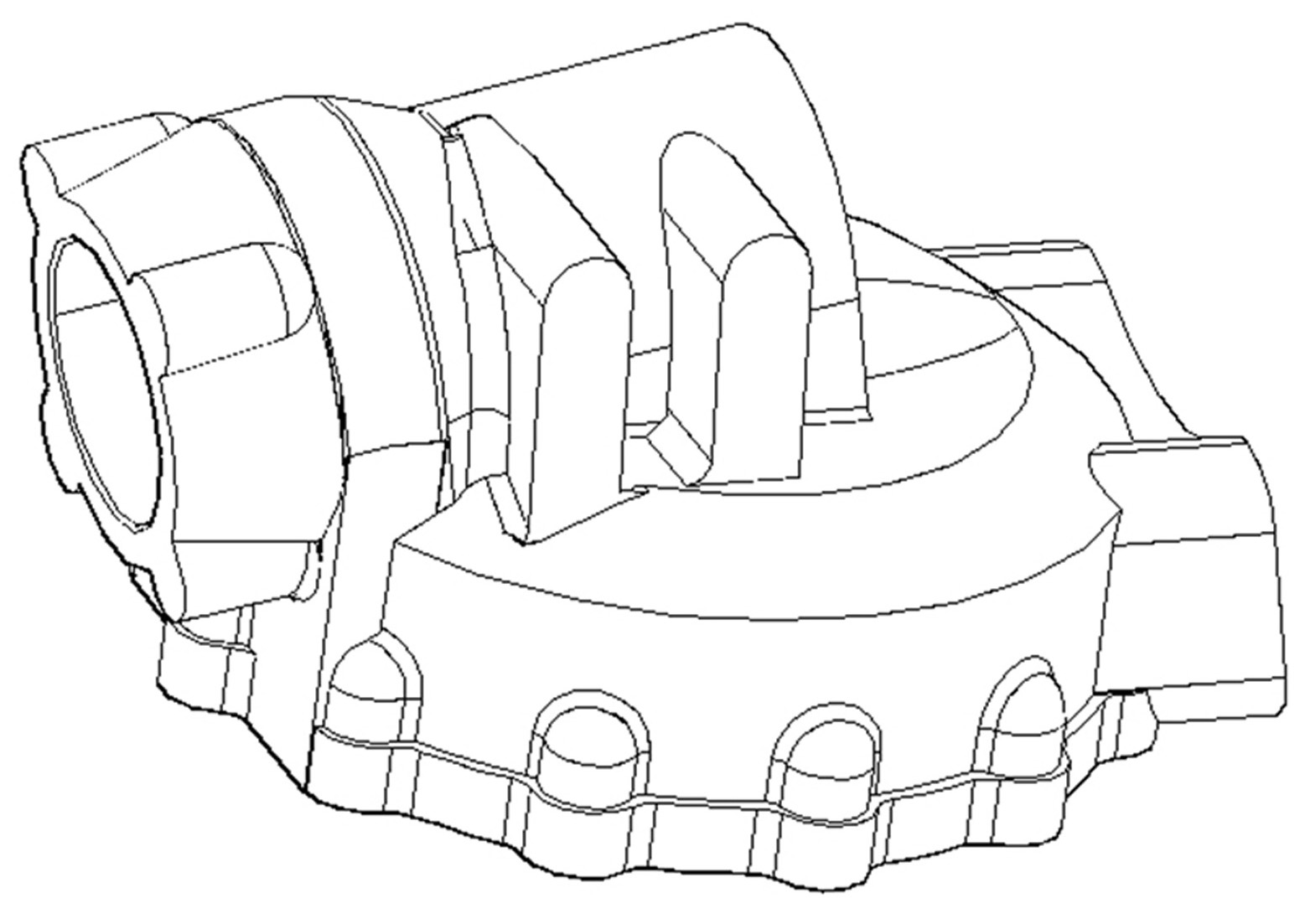

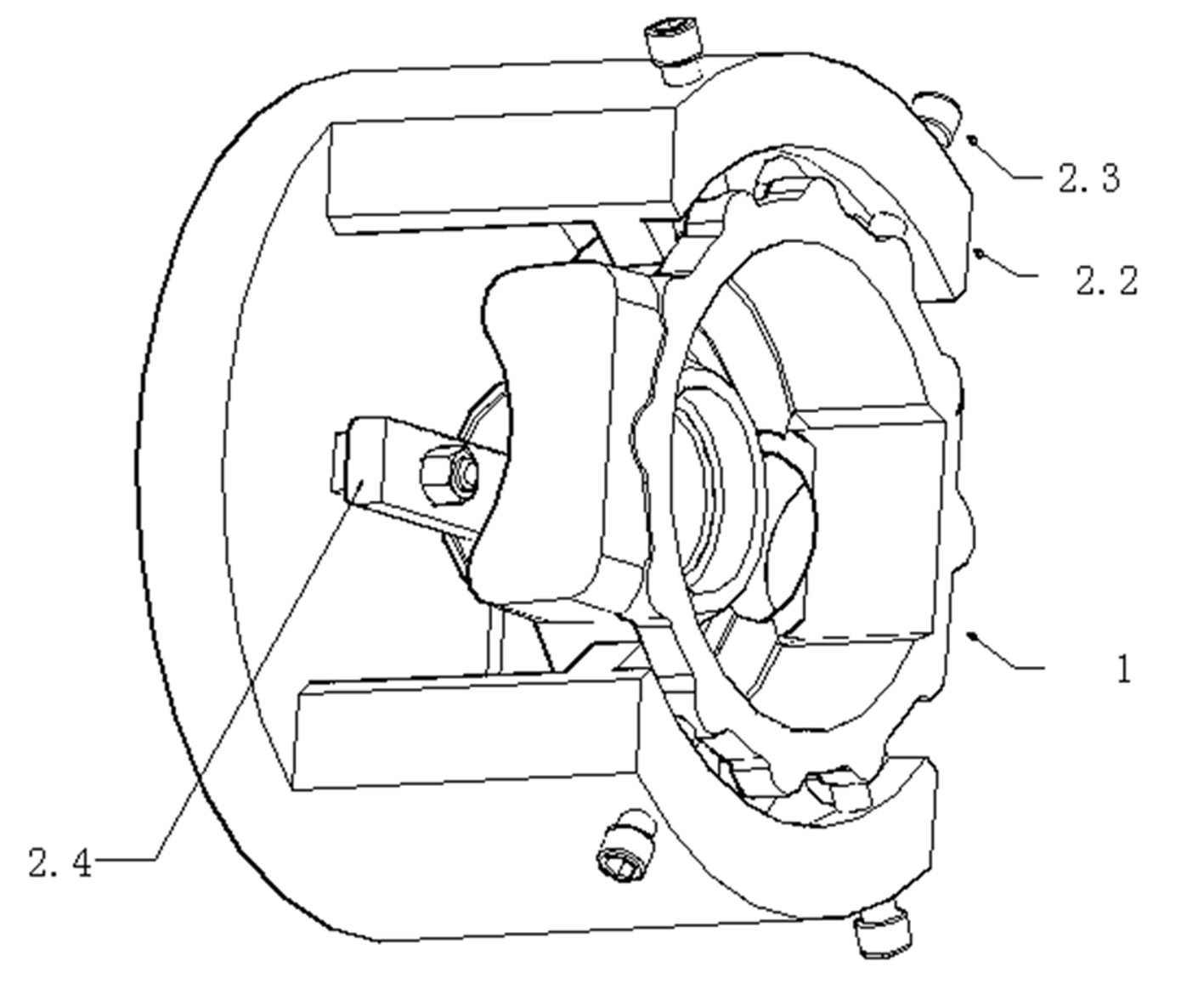

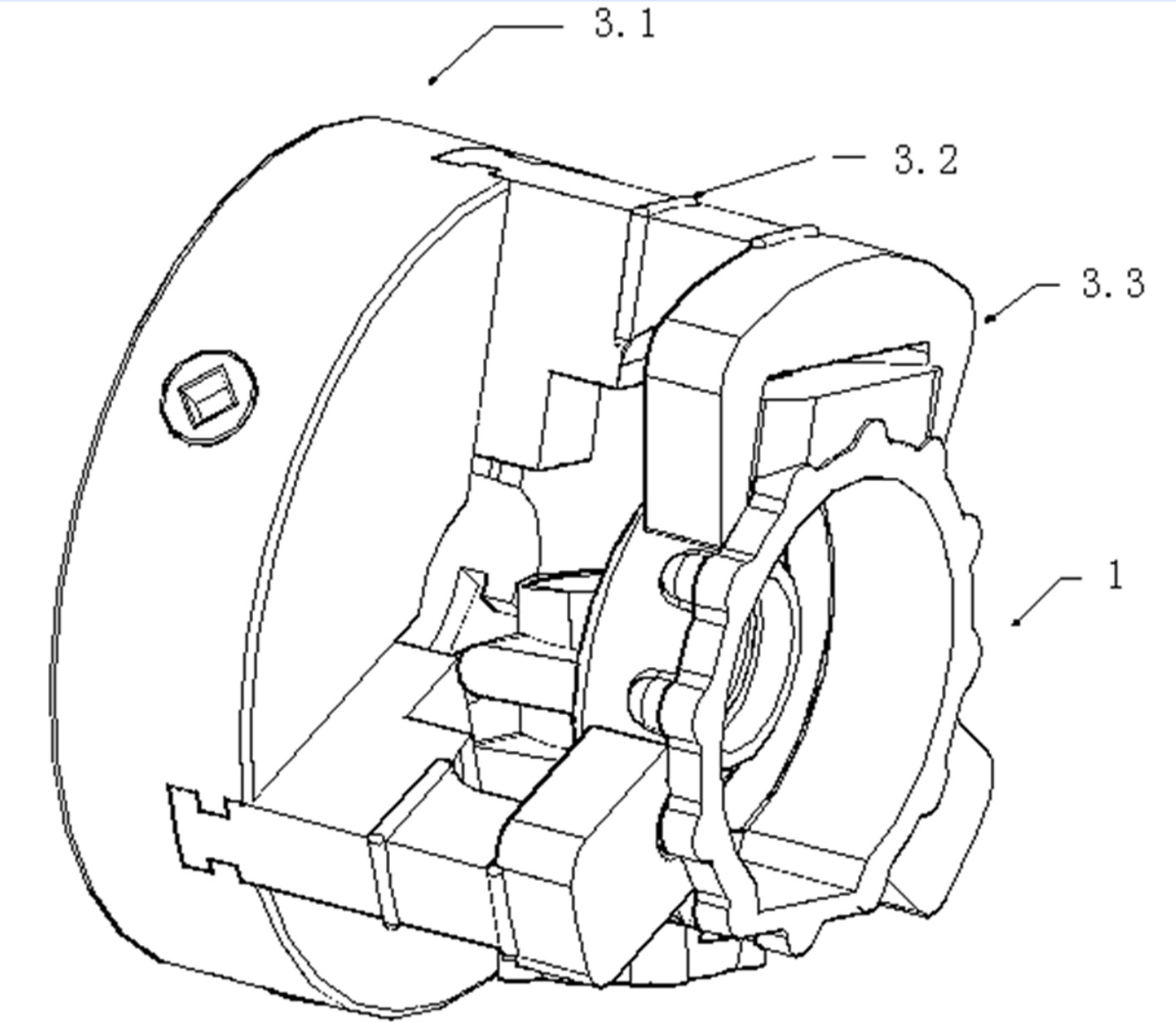

[0014] A three-jaw chuck, comprising a three-jaw chuck body 3.1, on which three bevel teeth 3.2 of the three-jaw chuck body 3.1 are respectively provided with locking structures 3.3; The structure 3.3 corresponds to the shape of the corresponding part of the processed workpiece. After the processed workpiece is clamped in the clamping structure 3.3, the axis of the processed workpiece corresponds to the axis of the three-jaw chuck body 3.1.

[0015] The connection between the clamping structure 3.3 and each bevel tooth 3.2 is a fixed connection or a detachable connection.

[0016] The fixed connection between the locking structure 3.3 and the respective bevel teeth 3.2 is realized by welding.

[0017] The realization structure of the detachable connection between the locking structure 3.3 and the respective bevel tooth 3.2 is that a correspond...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com